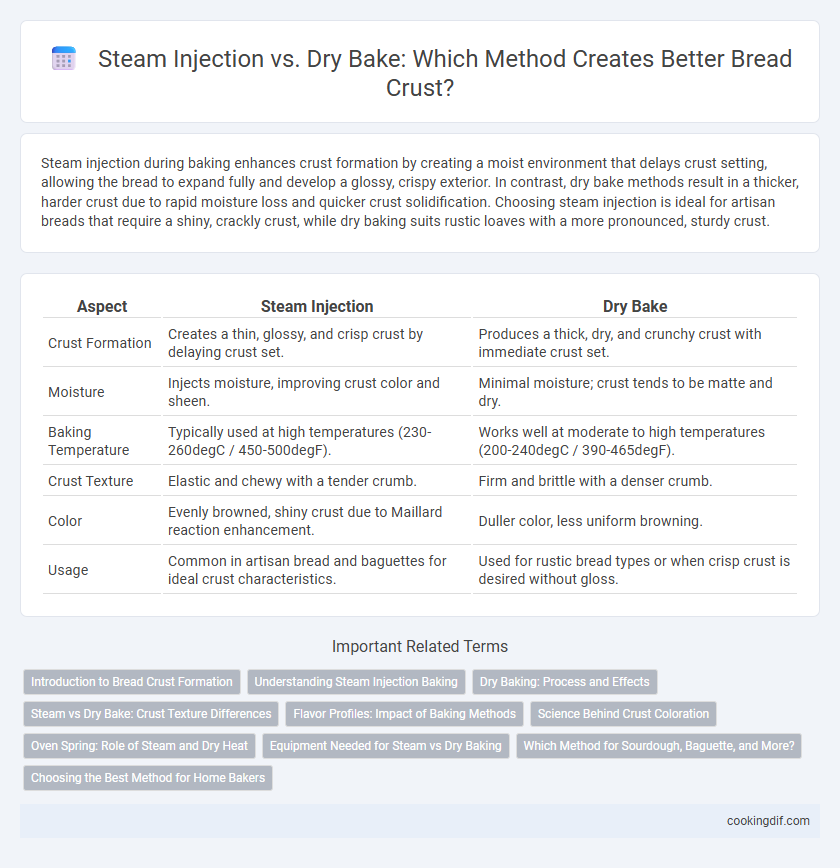

Steam injection during baking enhances crust formation by creating a moist environment that delays crust setting, allowing the bread to expand fully and develop a glossy, crispy exterior. In contrast, dry bake methods result in a thicker, harder crust due to rapid moisture loss and quicker crust solidification. Choosing steam injection is ideal for artisan breads that require a shiny, crackly crust, while dry baking suits rustic loaves with a more pronounced, sturdy crust.

Table of Comparison

| Aspect | Steam Injection | Dry Bake |

|---|---|---|

| Crust Formation | Creates a thin, glossy, and crisp crust by delaying crust set. | Produces a thick, dry, and crunchy crust with immediate crust set. |

| Moisture | Injects moisture, improving crust color and sheen. | Minimal moisture; crust tends to be matte and dry. |

| Baking Temperature | Typically used at high temperatures (230-260degC / 450-500degF). | Works well at moderate to high temperatures (200-240degC / 390-465degF). |

| Crust Texture | Elastic and chewy with a tender crumb. | Firm and brittle with a denser crumb. |

| Color | Evenly browned, shiny crust due to Maillard reaction enhancement. | Duller color, less uniform browning. |

| Usage | Common in artisan bread and baguettes for ideal crust characteristics. | Used for rustic bread types or when crisp crust is desired without gloss. |

Introduction to Bread Crust Formation

Bread crust formation primarily depends on baking methods where steam injection introduces moisture to delay crust hardening, resulting in a thinner, crispier crust. Dry baking promotes rapid moisture evaporation, creating a thicker, denser, and darker crust due to Maillard reactions and caramelization on the dough surface. The choice between steam injection and dry bake significantly affects the texture, color, and overall sensory qualities of the bread crust.

Understanding Steam Injection Baking

Steam injection baking enhances crust formation by introducing moisture at the start of baking, which delays crust setting and allows the dough to expand more fully. This method produces a glossy, crisp crust with a tender crumb compared to dry bake techniques, which result in a thicker, tougher crust due to rapid moisture loss. Understanding steam injection is crucial for bakers aiming to achieve artisanal bread characteristics with optimal volume and texture.

Dry Baking: Process and Effects

Dry baking involves baking bread without steam, allowing the crust to form through direct heat exposure that promotes Maillard reactions and caramelization. This process yields a thicker, darker, and crunchier crust with enhanced flavor complexity and a rustic appearance. Without steam, evaporation of surface moisture intensifies, resulting in a crackly texture and a more firm, robust crust structure.

Steam vs Dry Bake: Crust Texture Differences

Steam injection during bread baking produces a thin, glossy crust with a crackly texture by delaying starch gelatinization and promoting caramelization, enhancing oven spring and crust color. Dry bake methods result in a thicker, matte crust with a more uniform and firm texture due to faster moisture evaporation and less surface gelatinization. Steam also helps form a crispy crust by creating a humid environment that prevents premature drying, while dry baking leads to a sturdier crust that is less prone to cracking.

Flavor Profiles: Impact of Baking Methods

Steam injection during baking enhances crust development by promoting a glossy, thin, and slightly chewy exterior with complex caramelized flavors due to Maillard reactions. Dry bake methods produce a thicker, crunchier crust with more pronounced toasty and nutty notes, emphasizing a robust, rustic flavor profile. The choice between steam injection and dry baking directly influences the sensory experience, balancing moisture retention and crust texture in artisanal bread.

Science Behind Crust Coloration

Steam injection during the initial baking phase promotes Maillard reactions by maintaining surface moisture, which enhances enzymatic activity and results in a glossy, caramelized crust with deeper brown hues. In contrast, dry baking accelerates water evaporation, leading to a thicker, matte crust with lighter coloration due to limited sugar caramelization. The interplay of heat, moisture, and protein-sugar interactions fundamentally determines crust texture and color intensity in artisanal bread baking.

Oven Spring: Role of Steam and Dry Heat

Steam injection during the initial baking phase significantly enhances oven spring by keeping the dough surface moist, delaying crust formation, and allowing maximum expansion. Dry bake, lacking moisture, causes immediate crust hardening, limiting the bread's rise and resulting in a denser crumb. The controlled use of steam optimizes crust texture and volume, while dry heat promotes a thicker, crisper crust with reduced oven spring.

Equipment Needed for Steam vs Dry Baking

Steam injection ovens require specialized equipment such as steam generators or boilers integrated into the baking chamber to produce consistent, controllable steam levels essential for crust development. In contrast, dry baking can be performed in traditional convection ovens without additional steam equipment, relying on high heat and air circulation to form a crust. The investment and maintenance for steam injection setups are generally higher due to the complexity of the steam delivery systems compared to the simpler infrastructure needed for dry baking.

Which Method for Sourdough, Baguette, and More?

Steam injection creates a glossy, blistered crust ideal for sourdough by promoting oven spring and a chewy texture, while dry baking produces a thicker, crunchier crust preferred for baguettes. Sourdough benefits from steam to maintain moisture during the initial bake, enhancing crust elasticity and caramelization. Baguettes often favor dry baking to achieve their characteristic crispness and golden hue without moisture softening the crust.

Choosing the Best Method for Home Bakers

Steam injection creates a moist environment that promotes a thin, crispy crust with a glossy finish, ideal for artisan-style breads, while dry baking yields a thicker, crunchier crust suited for rustic loaves. Home bakers benefit from steam methods using simple tray water or misting techniques in conventional ovens to mimic professional steam injection systems. Selecting between steam and dry bake depends on desired crust texture and available kitchen equipment, making steam injection the preferred choice for refined crust quality at home.

Steam injection vs dry bake for crust formation Infographic

cookingdif.com

cookingdif.com