Retarding and cold proofing are techniques used to control yeast activity during bread fermentation by slowing gas production. Retarding involves placing dough in a refrigerator immediately after mixing to develop flavor and improve texture over time. Cold proofing typically refers to fermenting the dough slowly at low temperatures, allowing for better gluten structure and enhanced crumb quality.

Table of Comparison

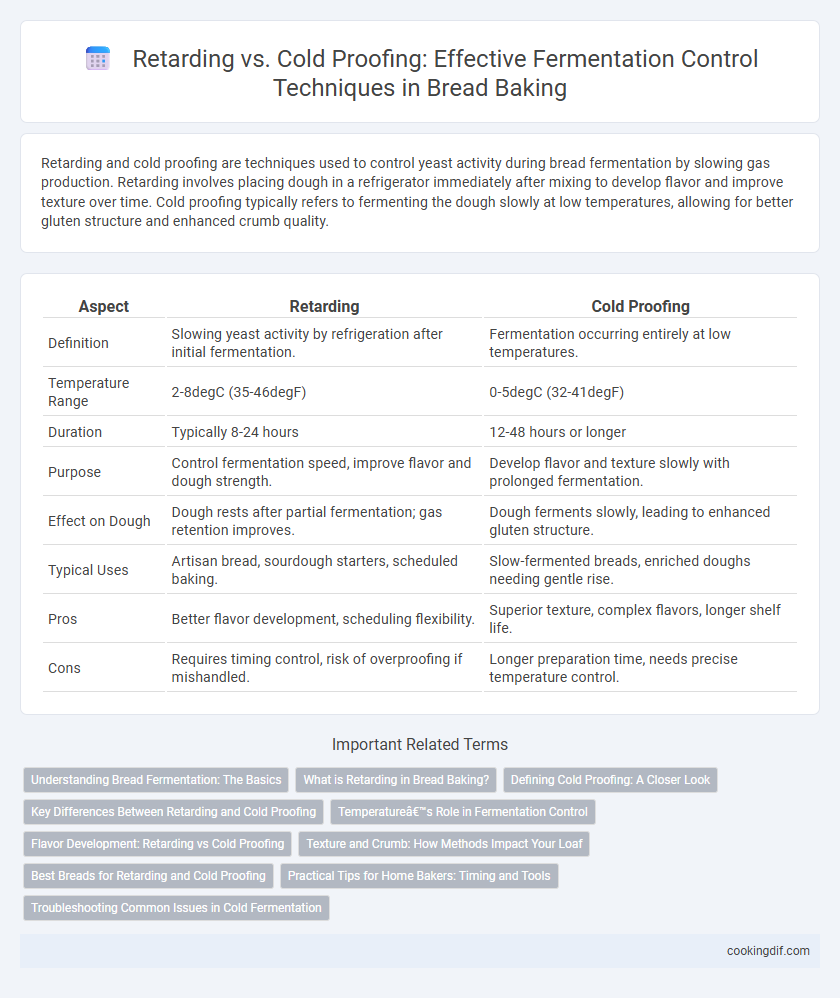

| Aspect | Retarding | Cold Proofing |

|---|---|---|

| Definition | Slowing yeast activity by refrigeration after initial fermentation. | Fermentation occurring entirely at low temperatures. |

| Temperature Range | 2-8degC (35-46degF) | 0-5degC (32-41degF) |

| Duration | Typically 8-24 hours | 12-48 hours or longer |

| Purpose | Control fermentation speed, improve flavor and dough strength. | Develop flavor and texture slowly with prolonged fermentation. |

| Effect on Dough | Dough rests after partial fermentation; gas retention improves. | Dough ferments slowly, leading to enhanced gluten structure. |

| Typical Uses | Artisan bread, sourdough starters, scheduled baking. | Slow-fermented breads, enriched doughs needing gentle rise. |

| Pros | Better flavor development, scheduling flexibility. | Superior texture, complex flavors, longer shelf life. |

| Cons | Requires timing control, risk of overproofing if mishandled. | Longer preparation time, needs precise temperature control. |

Understanding Bread Fermentation: The Basics

Retarding and cold proofing slow down yeast activity by fermenting dough at low temperatures, allowing flavors to develop more fully without overproofing. Retarding involves placing shaped dough in the refrigerator after initial fermentation, while cold proofing typically occurs during the final rise before baking. Both techniques enhance bread texture and flavor by extending fermentation, improving gas retention, and stabilizing dough structure.

What is Retarding in Bread Baking?

Retarding in bread baking refers to the process of slowing down fermentation by placing the dough in a cold environment, typically around 38degF (3degC), to control flavor development and improve texture. This technique allows yeast activity to pause temporarily, extending fermentation time and enhancing dough strength and crust characteristics. Retarding is commonly used for doughs that require longer proofing periods without overproofing, resulting in more complex flavors and better oven spring.

Defining Cold Proofing: A Closer Look

Cold proofing, also known as retarding, is a fermentation technique where dough is placed in a controlled low-temperature environment, typically between 38degF to 50degF (3degC to 10degC), to slow yeast activity and extend fermentation time. This method enhances flavor development by allowing enzymes more time to break down starches and proteins, resulting in a more complex crumb structure and improved texture. Professional bakers utilize cold proofing to better manage dough scheduling and achieve consistent, artisanal-quality bread.

Key Differences Between Retarding and Cold Proofing

Retarding in bread fermentation involves slowing down yeast activity by refrigerating the dough after the initial rise to develop flavor and improve texture, whereas cold proofing refers specifically to the final rise of shaped dough at low temperatures before baking. Retarding typically occurs at temperatures around 38degF to 45degF (3degC to 7degC) over an extended period, often overnight, while cold proofing can be done at slightly higher temperatures to control dough expansion and surface drying. The key difference lies in timing and purpose: retarding enhances flavor development during bulk fermentation, whereas cold proofing controls the dough's final volume and readiness for oven spring.

Temperature’s Role in Fermentation Control

Retarding and cold proofing both leverage low temperatures to slow yeast activity during bread fermentation, enabling flavor development and improved texture over extended periods. Retarding typically occurs in the refrigerator at around 37degF (3degC), significantly delaying fermentation and allowing complex flavor compounds to form. Cold proofing at slightly higher temperatures, approximately 50degF to 60degF (10degC to 15.5degC), balances yeast activity and dough expansion, optimizing fermentation control for artisanal bread.

Flavor Development: Retarding vs Cold Proofing

Retarding fermentation involves placing the dough in a cooler environment, typically around 38-50degF (3-10degC), to slow yeast activity and extend fermentation time, which enhances complex flavor compounds and improves crumb texture. Cold proofing specifically refers to the final proof in the refrigerator, allowing the dough to develop a deeper, more nuanced flavor profile by encouraging enzymatic reactions while controlling gas production. Both techniques contribute to superior taste, but retarding offers more pronounced sour notes and aromatic richness due to prolonged yeast and bacterial activity.

Texture and Crumb: How Methods Impact Your Loaf

Retarding fermentation by refrigerating the dough slows yeast activity, allowing gluten to develop more fully, which results in a chewier texture and a more open, airy crumb. Cold proofing similarly extends fermentation time but can enhance flavor complexity by encouraging enzymatic activity while maintaining a tighter crumb structure in the final loaf. Understanding these methods lets bakers manipulate texture and crumb characteristics to achieve the desired bread quality.

Best Breads for Retarding and Cold Proofing

Retarding fermentation by refrigerating dough slows yeast activity, enhancing flavor complexity and improving crust texture, making it ideal for sourdough and artisan breads. Cold proofing is particularly effective for high-hydration doughs and enriched breads like brioche, as it controls fermentation speed while preserving moisture. Both methods optimize crumb structure and extend fermentation time, benefiting breads that require slow development for better taste and texture.

Practical Tips for Home Bakers: Timing and Tools

Retarding dough by placing it in the refrigerator slows fermentation, enhancing flavor and texture through extended enzyme activity, while cold proofing controls rise time and improves dough handling. Home bakers can optimize timing by refrigerating dough for 12 to 24 hours and using a digital kitchen thermometer to monitor internal dough temperature, ensuring consistent results. Tools like a clear-proofing box and a dough scraper help maintain proper humidity and shape during fermentation, making it easier to manage the process at home.

Troubleshooting Common Issues in Cold Fermentation

Cold proofing in bread fermentation often causes slower yeast activity, which can lead to underproofed dough and dense bread if not monitored closely. To troubleshoot, ensure the dough temperature remains consistently between 38degF and 50degF, as fluctuations can disrupt fermentation and gluten development. Monitoring dough rise times and adjusting refrigeration duration helps prevent issues like off-flavors and poor texture during cold fermentation.

Retarding vs Cold Proofing for fermentation control Infographic

cookingdif.com

cookingdif.com