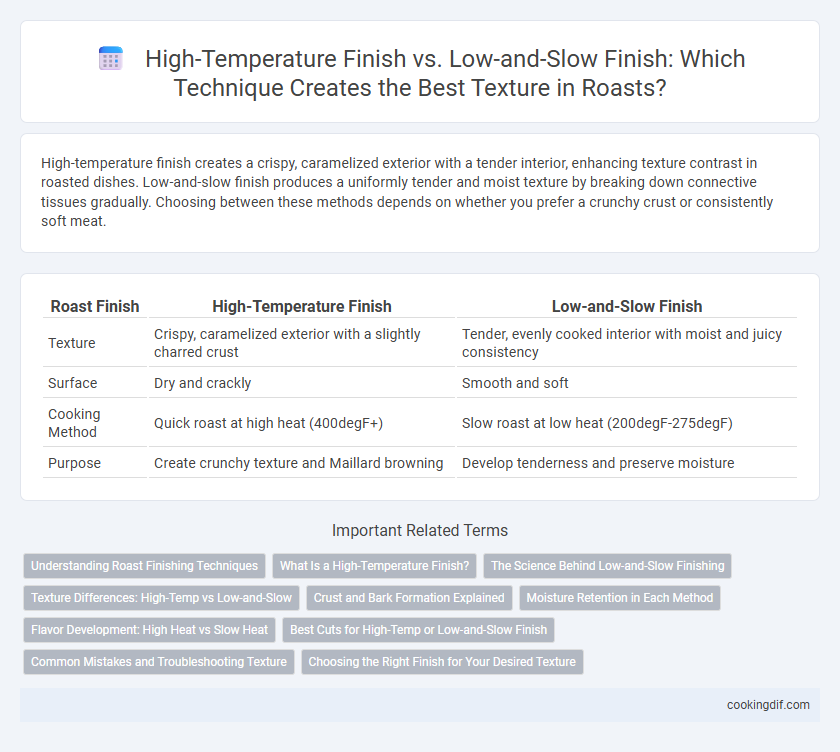

High-temperature finish creates a crispy, caramelized exterior with a tender interior, enhancing texture contrast in roasted dishes. Low-and-slow finish produces a uniformly tender and moist texture by breaking down connective tissues gradually. Choosing between these methods depends on whether you prefer a crunchy crust or consistently soft meat.

Table of Comparison

| Roast Finish | High-Temperature Finish | Low-and-Slow Finish |

|---|---|---|

| Texture | Crispy, caramelized exterior with a slightly charred crust | Tender, evenly cooked interior with moist and juicy consistency |

| Surface | Dry and crackly | Smooth and soft |

| Cooking Method | Quick roast at high heat (400degF+) | Slow roast at low heat (200degF-275degF) |

| Purpose | Create crunchy texture and Maillard browning | Develop tenderness and preserve moisture |

Understanding Roast Finishing Techniques

High-temperature finish in roasting creates a crisp, caramelized surface by rapidly elevating the bean's temperature, enhancing texture with a pronounced crunch and complex flavor compounds. Low-and-slow finish, by contrast, allows gradual development of the roast, resulting in a smoother, more uniform texture with subtle sweetness and balanced acidity. Mastering these finishing techniques enables precise control over bean texture, optimizing sensory experience and roast profile consistency.

What Is a High-Temperature Finish?

A high-temperature finish in roasting involves rapidly increasing the heat towards the end of the roast, enhancing the Maillard reaction and creating a crisp, caramelized texture on the surface of the beans. This method intensifies the development of complex flavors and produces a more pronounced, crunchy exterior compared to low-and-slow finishes that yield smoother, evenly developed textures. Temperature peaks around 450degF to 480degF characterize high-temperature finishes, significantly impacting the final cup's mouthfeel and aroma.

The Science Behind Low-and-Slow Finishing

Low-and-slow finishing in roasting enhances texture by allowing gradual Maillard reaction progression, which develops complex flavor profiles and tenderizes the product through controlled protein denaturation. This method promotes even heat distribution, reducing surface charring and preserving moisture for a juicy, consistent bite. High-temperature finishes, in contrast, speed up crust formation but often create a drier, less uniform texture due to rapid surface caramelization and moisture loss.

Texture Differences: High-Temp vs Low-and-Slow

High-temperature finish creates a crisp, crunchy exterior with a caramelized, complex texture due to rapid Maillard reactions. Low-and-slow finish yields a tender, evenly cooked interior with succulent juiciness and a soft bite, preserving moisture and enhancing connective tissue breakdown. The contrast between a brittle crust and a melt-in-mouth interior defines the textural distinction of high-temp versus low-and-slow roasting methods.

Crust and Bark Formation Explained

High-temperature roasting promotes rapid crust and bark formation through Maillard reactions and caramelization, creating a crisp, flavorful exterior with complex aromas. Low-and-slow finishes develop a thicker, more evenly textured bark by allowing gradual moisture evaporation and collagen breakdown over extended time. The choice influences not only texture but also the depth of flavor and visual appeal in the final roast.

Moisture Retention in Each Method

High-temperature roasting creates a crisp, caramelized crust that locks in juices quickly, resulting in a texture with a contrast between a crunchy exterior and tender interior while retaining moderate moisture. Low-and-slow finishes allow gradual moisture redistribution, producing uniformly tender meat with enhanced juiciness and minimal moisture loss throughout the cooking process. Choosing between these methods depends on desired texture--high heat excels in creating a textured crust, whereas low-and-slow optimizes overall moisture retention and tenderness.

Flavor Development: High Heat vs Slow Heat

High-temperature finish in roasting rapidly develops Maillard reactions, intensifying flavors with robust caramelization and creating a crisp, bold texture. Low-and-slow finish allows enzymes more time to break down complex compounds, resulting in nuanced, layered flavors and a tender, balanced mouthfeel. Flavor development differs as high heat emphasizes sharp, smoky notes, while slow heat highlights sweetness and depth.

Best Cuts for High-Temp or Low-and-Slow Finish

High-temperature finish excels with tender cuts like ribeye and sirloin, delivering a crispy crust while locking in juiciness. Low-and-slow finish suits tougher, collagen-rich cuts such as brisket and chuck, breaking down connective tissue for a tender, melt-in-your-mouth texture. Choosing the right finish method enhances the mouthfeel and flavor profile specific to each cut's muscle composition and fat content.

Common Mistakes and Troubleshooting Texture

High-temperature finish in roasting often leads to a crispy, caramelized texture but can cause uneven cooking and burnt spots if the heat is too intense or applied too long. Low-and-slow finish promotes tender, evenly cooked meat; however, common mistakes include insufficient moisture retention and overcooking, resulting in a dry, fibrous texture. Troubleshooting texture involves balancing heat, monitoring internal temperatures, and adjusting cooking duration to achieve the desired tenderness without compromising juiciness.

Choosing the Right Finish for Your Desired Texture

High-temperature finishes create a crisp, caramelized exterior with a tender interior, ideal for achieving a crunchy texture in roasted dishes. Low-and-slow finishes allow collagen and fats to break down gradually, resulting in a juicy, fall-apart tenderness perfect for slow-roasted meats. Selecting the right finish depends on whether a crisp crust or melt-in-your-mouth softness best suits your desired texture and flavor profile.

High-Temperature Finish vs Low-and-Slow Finish for Texture Infographic

cookingdif.com

cookingdif.com