Bench rest allows dough to relax and hydrate after initial mixing, improving extensibility and making shaping easier. Bulk fermentation promotes yeast activity and flavor development as the dough ferments in one mass, enhancing texture and crumb structure. Choosing between bench rest and bulk fermentation depends on desired dough handling and final bread characteristics.

Table of Comparison

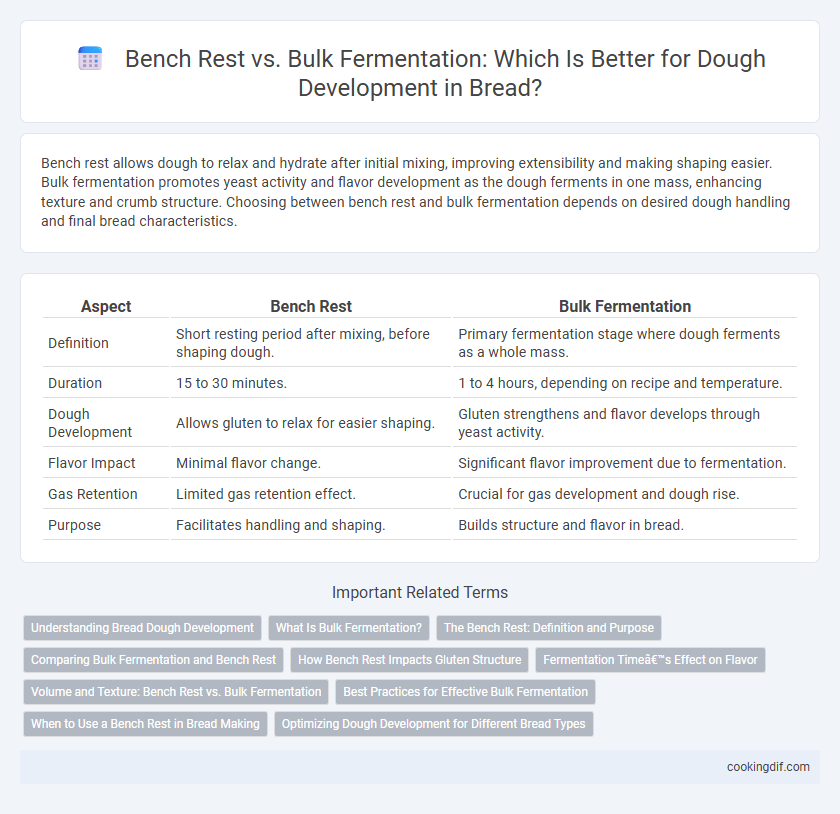

| Aspect | Bench Rest | Bulk Fermentation |

|---|---|---|

| Definition | Short resting period after mixing, before shaping dough. | Primary fermentation stage where dough ferments as a whole mass. |

| Duration | 15 to 30 minutes. | 1 to 4 hours, depending on recipe and temperature. |

| Dough Development | Allows gluten to relax for easier shaping. | Gluten strengthens and flavor develops through yeast activity. |

| Flavor Impact | Minimal flavor change. | Significant flavor improvement due to fermentation. |

| Gas Retention | Limited gas retention effect. | Crucial for gas development and dough rise. |

| Purpose | Facilitates handling and shaping. | Builds structure and flavor in bread. |

Understanding Bread Dough Development

Bench rest enhances gluten relaxation and yeast activity by allowing dough to rest after initial mixing, improving extensibility and shaping ability. Bulk fermentation involves the primary rise, during which yeast ferments sugars, producing gas that leavens the dough and develops flavor complexity. Understanding the balance between bench rest and bulk fermentation optimizes dough structure, texture, and final bread quality.

What Is Bulk Fermentation?

Bulk fermentation is the initial rise of dough after mixing, where yeast activity produces carbon dioxide, causing the dough to expand and develop flavor. This stage allows gluten networks to strengthen and enzymes to break down starches, enhancing texture and taste. Unlike bench rest, bulk fermentation occurs before dividing and shaping, making it essential for optimal dough development.

The Bench Rest: Definition and Purpose

The bench rest is a short, intermediate dough fermentation period that occurs after initial mixing and before shaping, allowing gluten strands to relax and the dough to hydrate evenly. This rest improves dough extensibility, making shaping easier and preventing overworking, which enhances the final bread's texture and crumb structure. By controlling the bench rest duration, bakers optimize fermentation timing to develop flavor and dough strength effectively.

Comparing Bulk Fermentation and Bench Rest

Bulk fermentation allows yeast to develop flavor and gluten structure over an extended period, producing more complex and airy bread crumb. Bench rest, a shorter resting phase after shaping, relaxes the gluten for easier shaping and final proofing without significant fermentation activity. Comparing both, bulk fermentation primarily enhances dough volume and taste, whereas bench rest optimizes dough elasticity and handling before baking.

How Bench Rest Impacts Gluten Structure

Bench rest allows the dough to relax after initial mixing, promoting gluten strand realignment and improved extensibility, which results in a more elastic and manageable dough. This resting period reduces dough resistance during shaping by relieving internal tension and encouraging a more cohesive gluten network. Consequently, bench rest enhances the dough's ability to trap gas, contributing to better crumb structure and volume in the final baked bread.

Fermentation Time’s Effect on Flavor

Bench rest allows dough to undergo a short fermentation period, resulting in a mild flavor profile with less complexity. Bulk fermentation extends fermentation time, encouraging yeast and bacterial activity that produces rich, tangy, and nuanced flavors essential for artisan bread. Optimizing bulk fermentation time enhances dough development by deepening flavor through organic acid and alcohol formation.

Volume and Texture: Bench Rest vs. Bulk Fermentation

Bulk fermentation allows dough to develop greater volume and a more open crumb structure due to extended yeast activity and gas retention, enhancing texture with increased airiness and chewiness. Bench rest, occurring after bulk fermentation, helps relax gluten strands, making the dough easier to shape without significantly altering volume but contributing to a finer, more uniform crumb. Optimizing the balance between bulk fermentation and bench rest times is critical to achieving optimal bread volume and texture.

Best Practices for Effective Bulk Fermentation

Bulk fermentation is essential for dough development, allowing yeast to produce carbon dioxide and develop gluten structure effectively. Maintaining a consistent temperature between 75-80degF (24-27degC) and fermenting for 1 to 3 hours optimizes yeast activity and flavor complexity. Using a glass or plastic container with a tight cover helps retain moisture and prevents dough surface drying during the bulk fermentation stage.

When to Use a Bench Rest in Bread Making

Bench rest is ideal for doughs requiring short fermentation times, such as high-hydration or enriched doughs, where gluten relaxation and easier shaping are essential. It allows the dough to rest at room temperature for 20 to 30 minutes, improving extensibility without overfermentation. Use a bench rest when immediate baking follows shaping or when the dough needs a quick gluten development boost before bulk fermentation.

Optimizing Dough Development for Different Bread Types

Bench rest allows gluten relaxation and yeast activity to stabilize, enhancing dough extensibility for artisan breads like ciabatta, while bulk fermentation promotes total yeast fermentation time, developing complex flavors essential in sourdough and rye breads. Optimizing dough development depends on balancing fermentation time, hydration, and temperature specific to bread types, ensuring desired crumb structure and crust characteristics. Fine-tuning the bench rest and bulk fermentation phases influences gas retention and gluten network strength, crucial for achieving optimal volume and texture in enveloping crust and open crumb profiles.

Bench rest vs bulk fermentation for dough development Infographic

cookingdif.com

cookingdif.com