Roasting lamb using indirect heat allows for slow, even cooking that preserves moisture and enhances tenderness, making it ideal for larger cuts. Direct heat, on the other hand, sears the exterior quickly, creating a flavorful crust but risking uneven cooking and dryness if not carefully monitored. Choosing between indirect and direct heat depends on desired texture and cooking time for the perfect roast lamb.

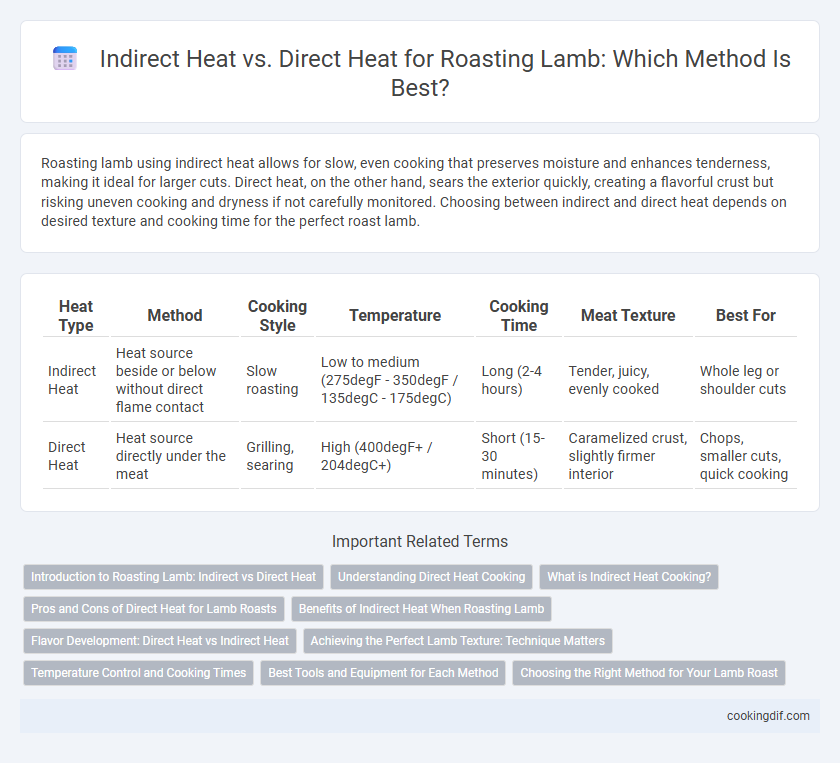

Table of Comparison

| Heat Type | Method | Cooking Style | Temperature | Cooking Time | Meat Texture | Best For |

|---|---|---|---|---|---|---|

| Indirect Heat | Heat source beside or below without direct flame contact | Slow roasting | Low to medium (275degF - 350degF / 135degC - 175degC) | Long (2-4 hours) | Tender, juicy, evenly cooked | Whole leg or shoulder cuts |

| Direct Heat | Heat source directly under the meat | Grilling, searing | High (400degF+ / 204degC+) | Short (15-30 minutes) | Caramelized crust, slightly firmer interior | Chops, smaller cuts, quick cooking |

Introduction to Roasting Lamb: Indirect vs Direct Heat

Indirect heat in roasting lamb allows slow, even cooking by surrounding the meat with gentle heat, preserving juiciness and tenderness. Direct heat exposes the lamb to intense flames or high temperatures, creating a seared crust and caramelized flavors but risks drying the interior if overcooked. Understanding the temperature and positioning of the lamb relative to the heat source optimizes texture and flavor in roasted lamb dishes.

Understanding Direct Heat Cooking

Direct heat cooking for roast lamb involves placing the meat close to an intense heat source, such as a grill or open flame, resulting in rapid surface searing that locks in juices and creates a flavorful crust. This method typically requires careful monitoring to prevent burning while achieving a caramelized exterior and a tender interior. Understanding direct heat cooking enhances the ability to produce succulent roast lamb with a distinct char and robust aroma.

What is Indirect Heat Cooking?

Indirect heat cooking involves placing the roast lamb away from the direct flame or heat source, allowing the meat to cook slowly and evenly through convection. This method preserves moisture, ensuring a tender and juicy lamb roast with a flavorful crust. Ideal for larger cuts, indirect heat reduces the risk of burning while enhancing the development of rich, caramelized flavors.

Pros and Cons of Direct Heat for Lamb Roasts

Direct heat for lamb roasts offers faster cooking times and a rich, caramelized crust enhancing flavor through Maillard reaction. However, it carries the risk of uneven cooking, with exterior charring before the interior reaches the desired doneness. This method requires careful attention to avoid drying out lean cuts, making it more suitable for well-marbled lamb sections.

Benefits of Indirect Heat When Roasting Lamb

Indirect heat offers a slow and even cooking process that enhances the tenderness and juiciness of roast lamb by allowing heat to penetrate gradually without drying the meat. This method reduces the risk of charring and preserves the lamb's natural flavors and moisture, resulting in a succulent and flavorful roast. Cooking with indirect heat also promotes better control over temperature, ensuring the lamb reaches the ideal doneness consistently.

Flavor Development: Direct Heat vs Indirect Heat

Direct heat cooking sears the surface of roast lamb, creating a caramelized crust through the Maillard reaction that intensifies flavor and adds a smoky aroma. Indirect heat allows slow, even cooking, preserving juiciness and tenderness while infusing subtle, complex flavors as the lamb slowly roasts. Balancing direct heat for crust formation with indirect heat for thorough cooking maximizes flavor development in roast lamb.

Achieving the Perfect Lamb Texture: Technique Matters

Achieving the perfect lamb texture relies heavily on balancing indirect heat, which gently cooks the meat, preserving juiciness and tenderness, with direct heat that sears the exterior, creating a flavorful crust. Indirect heat at lower temperatures allows collagen in the lamb to break down slowly, resulting in a succulent, melt-in-your-mouth roast. Combining these methods ensures the lamb retains moisture inside while developing a rich, caramelized outer layer crucial for an ideal roast.

Temperature Control and Cooking Times

Indirect heat for roast lamb provides consistent temperature control around 300-325degF (150-160degC), allowing slow, even cooking that results in tender, juicy meat with a cooking time of approximately 20 minutes per pound. Direct heat involves higher temperatures of 400-450degF (200-230degC) and faster cooking times, usually 10-15 minutes per pound, but requires careful monitoring to prevent overcooking or charring. Choosing indirect heat minimizes temperature fluctuations, making it ideal for achieving evenly cooked lamb with a desirable pink center.

Best Tools and Equipment for Each Method

Indirect heat roasting of lamb works best with equipment such as a rotisserie, smoker, or covered grill that maintains a consistent temperature without direct flame contact, preserving juiciness and even cooking. Direct heat roasting requires sturdy grill grates, tongs, and reliable meat thermometers to monitor temperature and achieve a flavorful sear with caramelized crust. Using cast iron pans or drip trays enhances heat distribution and reduces flare-ups, optimizing results for both cooking methods.

Choosing the Right Method for Your Lamb Roast

Choosing the right method for roasting lamb depends on the cut and desired texture; direct heat suits smaller, tender cuts for a quick, flavorful crust, while indirect heat is ideal for larger, tougher cuts requiring slow, even cooking to achieve tenderness. Indirect heat allows the lamb to roast at lower temperatures, preserving juiciness and enhancing flavor development through gradual Maillard reactions. Understanding these differences ensures optimal results, balancing cooking time, temperature, and meat quality for a perfect roast lamb.

Indirect heat vs Direct heat for roast lamb Infographic

cookingdif.com

cookingdif.com