Steam injection creates a humid environment in the oven, allowing the bread crust to develop a glossy, crisp outer layer by delaying starch gelatinization and promoting oven spring. Using a Dutch oven traps steam released from the dough itself, mimicking professional steam injection and producing a similarly crisp, well-blistered crust. Both methods enhance crust texture, but steam injection offers more precise humidity control, while the Dutch oven provides a convenient home-baking alternative.

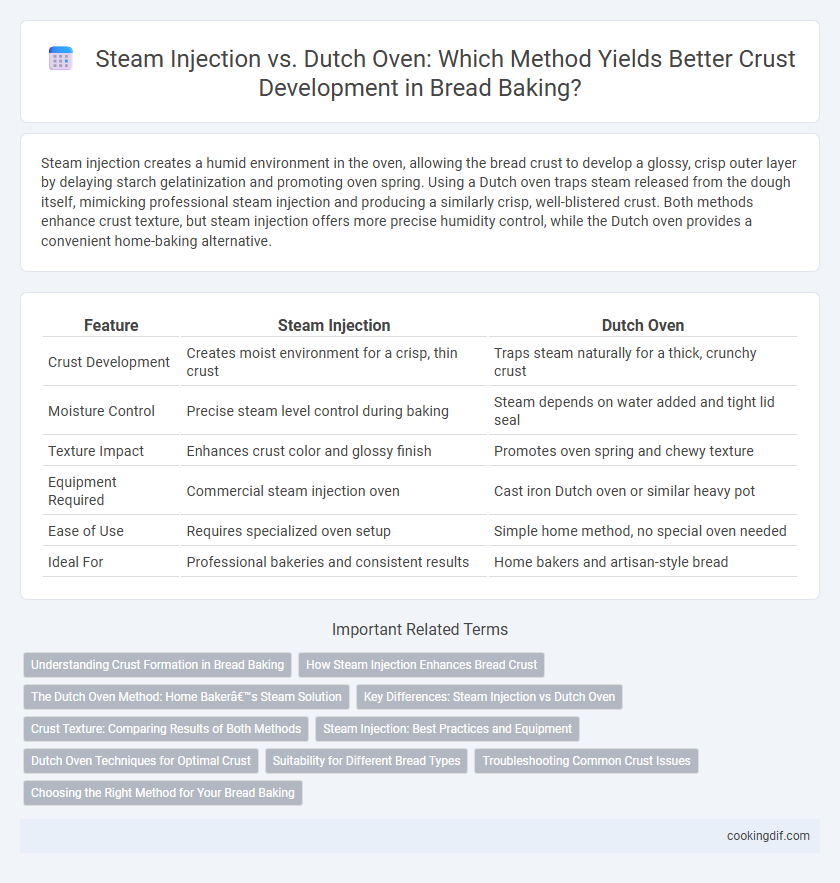

Table of Comparison

| Feature | Steam Injection | Dutch Oven |

|---|---|---|

| Crust Development | Creates moist environment for a crisp, thin crust | Traps steam naturally for a thick, crunchy crust |

| Moisture Control | Precise steam level control during baking | Steam depends on water added and tight lid seal |

| Texture Impact | Enhances crust color and glossy finish | Promotes oven spring and chewy texture |

| Equipment Required | Commercial steam injection oven | Cast iron Dutch oven or similar heavy pot |

| Ease of Use | Requires specialized oven setup | Simple home method, no special oven needed |

| Ideal For | Professional bakeries and consistent results | Home bakers and artisan-style bread |

Understanding Crust Formation in Bread Baking

Steam injection creates a humid environment in the oven that delays crust formation, allowing the bread to expand fully and develop a glossy, thin crust with a tender crumb. The Dutch oven traps steam released by the dough itself in a closed environment, resulting in a similar effect where moisture is retained and a crisp, thick crust forms as the bread bakes. Both methods enhance Maillard reactions and caramelization, key processes responsible for the rich color, texture, and flavor of the crust in artisanal bread baking.

How Steam Injection Enhances Bread Crust

Steam injection enhances bread crust by creating a humid environment inside the oven that delays the setting of the crust, allowing the dough to expand fully and develop a thin, crisp outer layer. The presence of steam facilitates gelatinization of starches on the bread's surface, resulting in a glossy, crackly crust with improved texture. This technique promotes Maillard reaction, intensifying flavor and creating a rich, golden-brown appearance that is difficult to achieve with a Dutch oven alone.

The Dutch Oven Method: Home Baker’s Steam Solution

The Dutch oven method creates an ideal steam environment by trapping moisture released from the dough, resulting in a crisp, well-developed crust without any special equipment. Compared to steam injection ovens, the Dutch oven evenly distributes heat and moisture, promoting optimal crust browning and a glossy finish. Home bakers favor this technique for its simplicity and ability to replicate professional steam conditions, enhancing artisanal bread texture and flavor.

Key Differences: Steam Injection vs Dutch Oven

Steam injection bread ovens release controlled steam directly into the baking chamber, promoting a glossy, crisp crust by delaying starch gelatinization and allowing optimal oven spring. Dutch ovens create a self-contained steamy environment by trapping water vapor from the dough itself and any added moisture, resulting in consistent moisture retention and a thick, crackly crust. Key differences include steam injection offering precise steam control and faster heat recovery, while Dutch ovens are portable and accessible for home bakers without specialized equipment.

Crust Texture: Comparing Results of Both Methods

Steam injection produces a crisp, thin crust by maintaining high humidity during the initial baking phase, which delays crust formation and allows for significant oven spring. In contrast, Dutch oven baking traps steam released from the dough itself, creating a thick, chewy crust with a rustic texture and deep color. Both methods enhance crust texture effectively but differ in achieving either a delicate crunch or a substantial, hearty crust.

Steam Injection: Best Practices and Equipment

Steam injection ovens provide precise control over humidity, promoting superior crust development by enabling optimal gelatinization and caramelization during baking. Best practices include injecting steam at the initial baking phase to create a glossy, crisp crust while preventing premature drying of the dough surface. Essential equipment features include programmable steam injection systems, stainless steel steam chambers, and adjustable steam volume controls to ensure consistent moisture levels for artisanal quality bread crusts.

Dutch Oven Techniques for Optimal Crust

Dutch oven techniques create an optimal crust by trapping steam during the initial baking phase, which enhances crust caramelization and produces a crisp, golden exterior. Preheating the Dutch oven ensures consistent high heat, while removing the lid halfway allows moisture to escape, perfecting crust texture. This method replicates professional steam-injected ovens, making it ideal for artisan bread baking at home.

Suitability for Different Bread Types

Steam injection offers precise humidity control ideal for lean doughs like baguettes and ciabatta, promoting a crisp, thin crust by delaying crust formation during baking. Dutch ovens provide a sealed, moist environment perfect for artisan loaves such as sourdough and rustic boules, yielding a thick, chewy crust with a tender crumb. Both methods enhance crust development but vary in effectiveness based on bread hydration and dough composition.

Troubleshooting Common Crust Issues

Steam injection ovens create a humid environment that promotes a glossy, crisp crust by preventing premature hardening of the dough surface, effectively reducing issues like dull or cracked crusts. Dutch ovens trap natural steam released from the dough, enhancing oven spring and developing a thick, crunchy crust, which helps resolve problems of flat or overly thick crusts. For crust troubleshooting, steam injection is ideal for consistent commercial-quality results, while Dutch ovens offer a simple, cost-effective solution for home bakers aiming to improve crust texture and color.

Choosing the Right Method for Your Bread Baking

Steam injection produces a glossy, crackly crust by introducing moisture early in baking, which enhances oven spring and gelatinizes starches on the bread surface. Dutch ovens trap steam released from the dough, creating a humid environment that mimics professional steam injection effects, resulting in a thick, chewy crust with deep color. Choosing between steam injection and a Dutch oven depends on your oven's capabilities and desired crust characteristics, with steam injection offering precise control and the Dutch oven providing an accessible, effective home-baking solution.

Steam Injection vs Dutch Oven for crust development Infographic

cookingdif.com

cookingdif.com