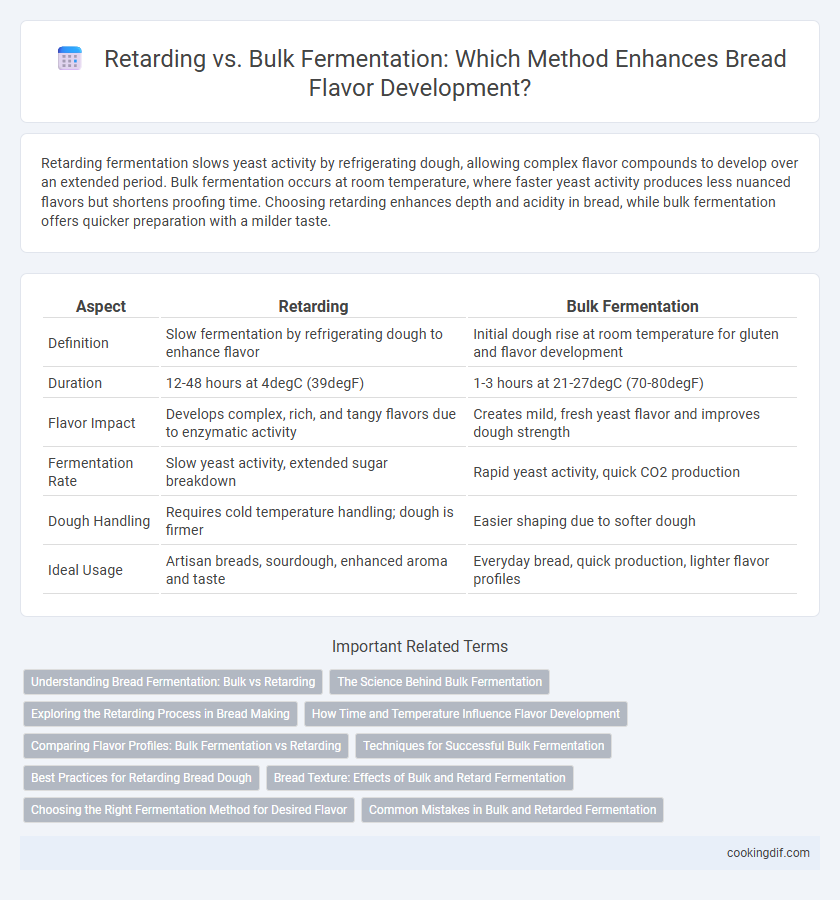

Retarding fermentation slows yeast activity by refrigerating dough, allowing complex flavor compounds to develop over an extended period. Bulk fermentation occurs at room temperature, where faster yeast activity produces less nuanced flavors but shortens proofing time. Choosing retarding enhances depth and acidity in bread, while bulk fermentation offers quicker preparation with a milder taste.

Table of Comparison

| Aspect | Retarding | Bulk Fermentation |

|---|---|---|

| Definition | Slow fermentation by refrigerating dough to enhance flavor | Initial dough rise at room temperature for gluten and flavor development |

| Duration | 12-48 hours at 4degC (39degF) | 1-3 hours at 21-27degC (70-80degF) |

| Flavor Impact | Develops complex, rich, and tangy flavors due to enzymatic activity | Creates mild, fresh yeast flavor and improves dough strength |

| Fermentation Rate | Slow yeast activity, extended sugar breakdown | Rapid yeast activity, quick CO2 production |

| Dough Handling | Requires cold temperature handling; dough is firmer | Easier shaping due to softer dough |

| Ideal Usage | Artisan breads, sourdough, enhanced aroma and taste | Everyday bread, quick production, lighter flavor profiles |

Understanding Bread Fermentation: Bulk vs Retarding

Bulk fermentation allows yeast to actively produce carbon dioxide and organic acids, enhancing dough flavor through prolonged enzymatic activity. Retarding slows fermentation by refrigeration, intensifying flavor complexity as yeast metabolism continues at a reduced rate. Understanding these processes helps bakers control flavor profiles by manipulating fermentation time and temperature.

The Science Behind Bulk Fermentation

Bulk fermentation is a critical phase in bread making where yeast activity produces carbon dioxide and organic acids, contributing to flavor complexity and crumb structure. During this stage, enzymes break down starches into simpler sugars, fueling yeast metabolism and enhancing the bread's aromatic profile through fermentation byproducts like alcohols and esters. Proper temperature control and duration in bulk fermentation optimize gluten development and acid production, resulting in a balanced tang and improved taste depth compared to retarding methods.

Exploring the Retarding Process in Bread Making

Retarding in bread making involves slowing down the fermentation process by refrigerating the dough, which enhances flavor complexity through prolonged enzymatic activity and acid development. This controlled slow fermentation allows yeast and bacteria to produce organic acids and alcohols that improve the dough's aroma, taste, and shelf life. Compared to bulk fermentation at room temperature, retarding intensifies flavor depth and creates a chewier crumb and crisper crust in the finished bread.

How Time and Temperature Influence Flavor Development

Time and temperature during retarding and bulk fermentation critically influence dough flavor development by controlling yeast activity and fermentation byproducts. Retarding fermentation at low temperatures slows yeast metabolism, enhancing acid production and complex flavor compounds over extended periods. Bulk fermentation at warmer temperatures accelerates yeast activity, producing robust flavors quickly but with less depth compared to cold retardation.

Comparing Flavor Profiles: Bulk Fermentation vs Retarding

Bulk fermentation develops a bread's flavor through active yeast activity and organic acid production, resulting in a robust, tangy, and complex taste with a moderately open crumb. Retarding, or cold fermentation, slows yeast metabolism, enhancing enzymatic reactions that generate deeper, more nuanced flavors characterized by subtle sweetness and improved crust caramelization. Comparing the two, bulk fermentation favors a livelier, more pronounced acidity while retarding produces mellow, multi-layered flavor notes with increased shelf life.

Techniques for Successful Bulk Fermentation

Successful bulk fermentation relies on precise temperature control, maintaining an ideal range between 75degF to 82degF to optimize yeast activity and enzyme function. Consistent folding or degassing every 30 to 45 minutes strengthens gluten structure and evenly distributes fermentation gases, enhancing crumb texture and flavor complexity. Monitoring dough elasticity and rise volume helps determine optimal fermentation duration, preventing overproofing and ensuring robust, nuanced flavor development.

Best Practices for Retarding Bread Dough

Retarding bread dough by refrigerating during bulk fermentation slows yeast activity, enhancing flavor complexity and improving crumb texture. Best practices include maintaining a consistent temperature between 38degF to 45degF and extending fermentation for 12 to 24 hours to maximize acidity and aromatic compounds. Avoid rapid temperature fluctuations and ensure airtight coverage to prevent surface drying and off-flavors.

Bread Texture: Effects of Bulk and Retard Fermentation

Bulk fermentation allows yeast activity to develop gluten structure, resulting in a bread crumb with a chewy, open texture and improved volume. Retarding fermentation slows yeast metabolism in the refrigerator, enhancing flavor complexity while promoting a tighter, more uniform crumb ideal for artisanal bread. The balance between bulk and retard fermentation directly influences the bread's texture, with extended retarding producing a denser crust and a moist, tender interior.

Choosing the Right Fermentation Method for Desired Flavor

Retarding fermentation by slowing down yeast activity in the refrigerator enhances complex, tangy flavors through prolonged enzymatic reactions, resulting in a more developed crust and crumb texture in bread. Bulk fermentation at room temperature accelerates yeast growth, producing a milder, sweeter flavor with a softer crumb and less pronounced sourness. Selecting the appropriate fermentation method depends on the desired flavor profile, with retarding preferred for richer, artisan-style breads and bulk fermentation suited to quicker, subtler-tasting loaves.

Common Mistakes in Bulk and Retarded Fermentation

Common mistakes in bulk fermentation include under-proofing or over-proofing the dough, leading to poor flavor development and dense texture. In retarded fermentation, improper temperature control can cause uneven yeast activity, resulting in inconsistent crumb and off-flavors. Neglecting to monitor fermentation times closely often reduces the complex taste profile that slow, cold fermentation is known for.

Retarding vs Bulk Fermentation for flavor development Infographic

cookingdif.com

cookingdif.com