Bulk fermentation allows the dough to develop flavor and structure as yeast ferments sugars, producing gases that cause initial rise. The final proof occurs after shaping, letting the dough expand further to achieve the desired volume and texture before baking. Proper control of both stages ensures optimal crumb development and oven spring in the finished bread.

Table of Comparison

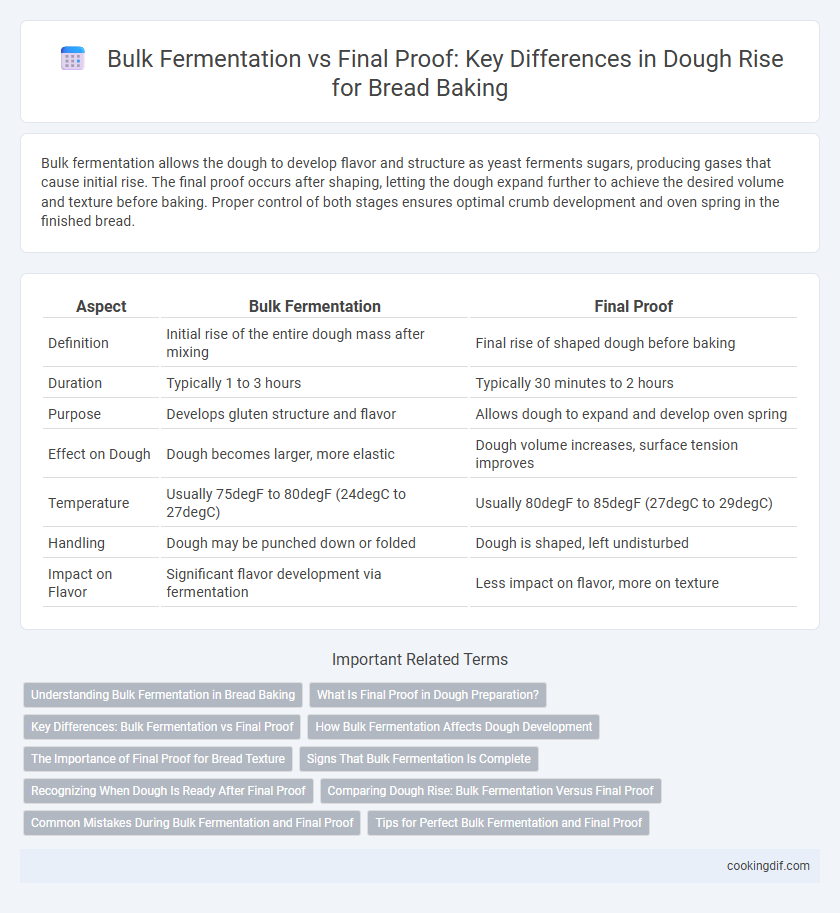

| Aspect | Bulk Fermentation | Final Proof |

|---|---|---|

| Definition | Initial rise of the entire dough mass after mixing | Final rise of shaped dough before baking |

| Duration | Typically 1 to 3 hours | Typically 30 minutes to 2 hours |

| Purpose | Develops gluten structure and flavor | Allows dough to expand and develop oven spring |

| Effect on Dough | Dough becomes larger, more elastic | Dough volume increases, surface tension improves |

| Temperature | Usually 75degF to 80degF (24degC to 27degC) | Usually 80degF to 85degF (27degC to 29degC) |

| Handling | Dough may be punched down or folded | Dough is shaped, left undisturbed |

| Impact on Flavor | Significant flavor development via fermentation | Less impact on flavor, more on texture |

Understanding Bulk Fermentation in Bread Baking

Bulk fermentation is the initial fermenting stage where yeast activity produces carbon dioxide, causing the dough to expand and develop flavor and gluten structure. This phase typically lasts from 1 to 3 hours, depending on dough temperature and yeast concentration, and is crucial for optimal gas retention and dough elasticity. Correctly managing bulk fermentation ensures a well-aerated crumb and enhanced bread texture before shaping and final proofing.

What Is Final Proof in Dough Preparation?

Final proof is the last stage of dough fermentation where the shaped dough rests before baking, allowing yeast activity to produce gas that expands the dough to its optimal volume. This stage enhances gluten development and flavor complexity while ensuring the dough reaches a proper rise for a light and airy crumb. Unlike bulk fermentation, which occurs before shaping, final proof determines the dough's final texture and oven spring.

Key Differences: Bulk Fermentation vs Final Proof

Bulk fermentation is the initial dough rise phase where yeast activity develops gluten structure and flavors, typically lasting several hours at controlled temperatures. Final proof occurs after shaping, allowing the dough to rise again before baking, ensuring optimal volume and crumb texture. Key differences include timing--bulk fermentation happens before shaping, while final proof is post-shaping--and their distinct impacts on dough strength versus dough aeration.

How Bulk Fermentation Affects Dough Development

Bulk fermentation significantly impacts dough development by allowing yeast to metabolize sugars and produce carbon dioxide, which contributes to dough aeration and gluten strengthening. This stage enhances flavor complexity through enzymatic reactions and develops dough structure, essential for achieving an optimal crumb texture. Proper control of bulk fermentation time and temperature directly influences dough elasticity and rise potential during the final proof.

The Importance of Final Proof for Bread Texture

Final proof is crucial for bread texture as it allows the dough to develop optimal gas retention and structure, resulting in a finer crumb and better volume. During this stage, yeast activity slows, and gluten strands relax, enhancing dough elasticity and preventing collapse during baking. Proper final proof ensures a light, airy loaf with a desirable crust and soft interior, distinguishing it from bulk fermentation, which primarily builds dough strength and flavor.

Signs That Bulk Fermentation Is Complete

Bulk fermentation is complete when dough has visibly expanded to approximately double its original size, showing a smooth surface with small, evenly distributed gas bubbles beneath. The dough should feel airy and soft but not overly sticky or slack, retaining some elasticity when gently pressed with a finger--the indentation should slowly spring back but not disappear entirely. These signs indicate that yeast fermentation has produced sufficient carbon dioxide, setting the stage for shaping and the final proof before baking.

Recognizing When Dough Is Ready After Final Proof

Dough is ready after the final proof when it has increased in size by about 50-75% and passes the finger poke test, where a gentle press leaves a slight indentation that slowly springs back. Overproofed dough will collapse or remain indented, indicating lost gas structure, while underproofed dough resists indentation and appears tight. Proper recognition of dough readiness impacts bread volume, crumb texture, and oven spring during baking.

Comparing Dough Rise: Bulk Fermentation Versus Final Proof

Bulk fermentation significantly impacts dough rise by allowing yeast to produce carbon dioxide and develop gluten structure over an extended period, resulting in enhanced flavor and texture. Final proof occurs after shaping, providing a shorter rise that refines the dough's volume and surface tension prior to baking. Comparing dough rise, bulk fermentation contributes to overall maturity and gas retention, while final proof ensures optimal oven spring and crumb consistency.

Common Mistakes During Bulk Fermentation and Final Proof

Common mistakes during bulk fermentation include underestimating fermentation time, resulting in dense bread, and over-fermenting, which causes weakened gluten structure and poor oven spring. During the final proof, common errors are underproofing, leading to tight crumb and insufficient rise, and overproofing, which causes dough collapse and flat loaves. Precise temperature control and timing are critical to avoid these pitfalls and achieve optimal dough rise and texture.

Tips for Perfect Bulk Fermentation and Final Proof

Bulk fermentation requires maintaining dough temperature between 75-78degF (24-26degC) for optimal yeast activity and flavor development. During the final proof, shape the dough gently and proof it until it doubles in size, typically 1 to 2 hours, while preventing over-proofing by monitoring dough strength and gas retention. Using a humid environment and covering the dough with a damp cloth or plastic wrap ensures consistent moisture levels, improving crumb texture and crust quality.

Bulk fermentation vs Final proof for dough rise Infographic

cookingdif.com

cookingdif.com