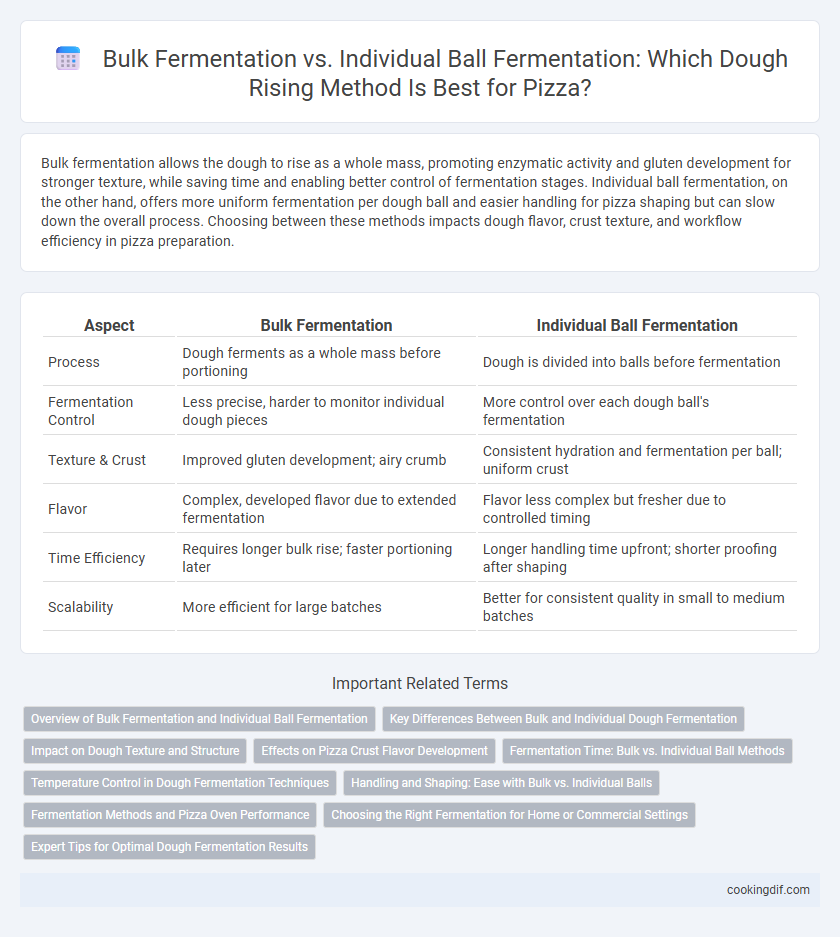

Bulk fermentation allows the dough to rise as a whole mass, promoting enzymatic activity and gluten development for stronger texture, while saving time and enabling better control of fermentation stages. Individual ball fermentation, on the other hand, offers more uniform fermentation per dough ball and easier handling for pizza shaping but can slow down the overall process. Choosing between these methods impacts dough flavor, crust texture, and workflow efficiency in pizza preparation.

Table of Comparison

| Aspect | Bulk Fermentation | Individual Ball Fermentation |

|---|---|---|

| Process | Dough ferments as a whole mass before portioning | Dough is divided into balls before fermentation |

| Fermentation Control | Less precise, harder to monitor individual dough pieces | More control over each dough ball's fermentation |

| Texture & Crust | Improved gluten development; airy crumb | Consistent hydration and fermentation per ball; uniform crust |

| Flavor | Complex, developed flavor due to extended fermentation | Flavor less complex but fresher due to controlled timing |

| Time Efficiency | Requires longer bulk rise; faster portioning later | Longer handling time upfront; shorter proofing after shaping |

| Scalability | More efficient for large batches | Better for consistent quality in small to medium batches |

Overview of Bulk Fermentation and Individual Ball Fermentation

Bulk fermentation involves fermenting the entire dough mass as a single unit, allowing yeast activity to develop flavor and gluten structure uniformly. Individual ball fermentation refers to dividing the dough into smaller, pre-portioned balls before the final rise, promoting consistent dough hydration and easier handling during shaping. Both methods impact dough texture, rise time, and final crust properties in pizza preparation.

Key Differences Between Bulk and Individual Dough Fermentation

Bulk fermentation involves allowing the entire dough mass to rise together, promoting stronger gluten development and enhanced flavor through extended enzyme activity. Individual ball fermentation, by contrast, occurs after dividing the dough, enabling more precise control over fermentation time and shaping, which can result in consistent crust texture and easier handling. Temperature regulation and fermentation environment impact both methods differently, affecting dough extensibility and overall pizza quality.

Impact on Dough Texture and Structure

Bulk fermentation allows yeast activity to develop evenly, resulting in a more consistent crumb structure and improved gluten elasticity in pizza dough. Individual ball fermentation promotes enhanced gas retention within each dough piece, producing a lighter, airier texture with distinct pockets of air. Both fermentation methods influence dough extensibility differently, impacting the final crust chewiness and structural integrity.

Effects on Pizza Crust Flavor Development

Bulk fermentation enhances gluten structure and allows yeast and enzymes to develop complex organic acids and alcohols, resulting in a richer, tangier pizza crust flavor. Individual ball fermentation slows fermentation in each dough ball, preserving more subtle aromatic compounds and humidity, producing a tender yet nuanced crust. Choosing between bulk and individual ball fermentation affects the balance of crust texture and flavor intensity in artisanal pizza making.

Fermentation Time: Bulk vs. Individual Ball Methods

Bulk fermentation significantly reduces overall dough rising time by allowing yeast activity across the entire mass, promoting uniform gas retention and gluten development. Individual ball fermentation requires longer periods for each dough portion to rise separately, as yeast works within limited space, often leading to more controlled gas production and finer texture. Temperature, hydration levels, and yeast concentration critically influence fermentation speed in both methods, impacting final pizza dough consistency and flavor profile.

Temperature Control in Dough Fermentation Techniques

Temperature control during bulk fermentation maintains an even heat distribution, promoting consistent yeast activity and flavor development across the entire dough mass. Individual ball fermentation allows precise temperature regulation for each dough portion, resulting in uniform texture and optimized fermentation for each pizza base. Fine-tuning temperature at these stages significantly influences dough elasticity, rise time, and the final crust quality.

Handling and Shaping: Ease with Bulk vs. Individual Balls

Bulk fermentation allows dough to develop flavor and gluten strength more uniformly, making it easier to handle and shape when divided into individual balls after the rise. Individual ball fermentation requires careful handling during the entire process, but provides better control of dough hydration and final shape consistency. Bulk fermentation is favored for large batches due to simplified handling, while individual ball fermentation suits small-scale, precise pizza dough production.

Fermentation Methods and Pizza Oven Performance

Bulk fermentation promotes consistent gas retention and gluten development across the entire dough batch, enhancing dough strength and elasticity essential for optimal oven spring. Individual ball fermentation allows for greater control over portion size and fermentation time, resulting in uniform rise and crust texture when baked in high-temperature pizza ovens. Proper fermentation methods directly influence oven performance by affecting dough hydration and air retention, which contribute to a well-balanced crust with ideal chewiness and char.

Choosing the Right Fermentation for Home or Commercial Settings

Bulk fermentation accelerates dough rising by allowing the entire batch to ferment together, enhancing gluten development and flavor complexity, ideal for commercial pizzerias managing large volumes efficiently. Individual ball fermentation provides more consistent and controllable results, making it suitable for home bakers who prioritize uniform dough texture and precise portioning. Selecting the appropriate fermentation method depends on production scale, time constraints, and desired dough characteristics, balancing speed and quality in both settings.

Expert Tips for Optimal Dough Fermentation Results

Bulk fermentation enhances dough flavor complexity and gluten strength by allowing yeast activity to develop uniformly before dividing into individual portions. Individual ball fermentation offers more precise control over dough hydration and texture, reducing oxidation and preserving air pockets for a lighter crust. Experts recommend combining both methods--starting with a bulk ferment for flavor development, followed by a short proof in individual balls to fine-tune dough elasticity and gas retention.

Bulk fermentation vs individual ball fermentation for dough rising Infographic

cookingdif.com

cookingdif.com