Hand-layered lasagna offers a textured, artisanal quality, with each noodle and filling precisely positioned to ensure even cooking and balanced flavors in every bite. Assembling in bulk prioritizes efficiency and uniformity, ideal for large-scale production where consistency and speed are essential. Choosing between these methods depends on the desired presentation, cooking time, and production volume.

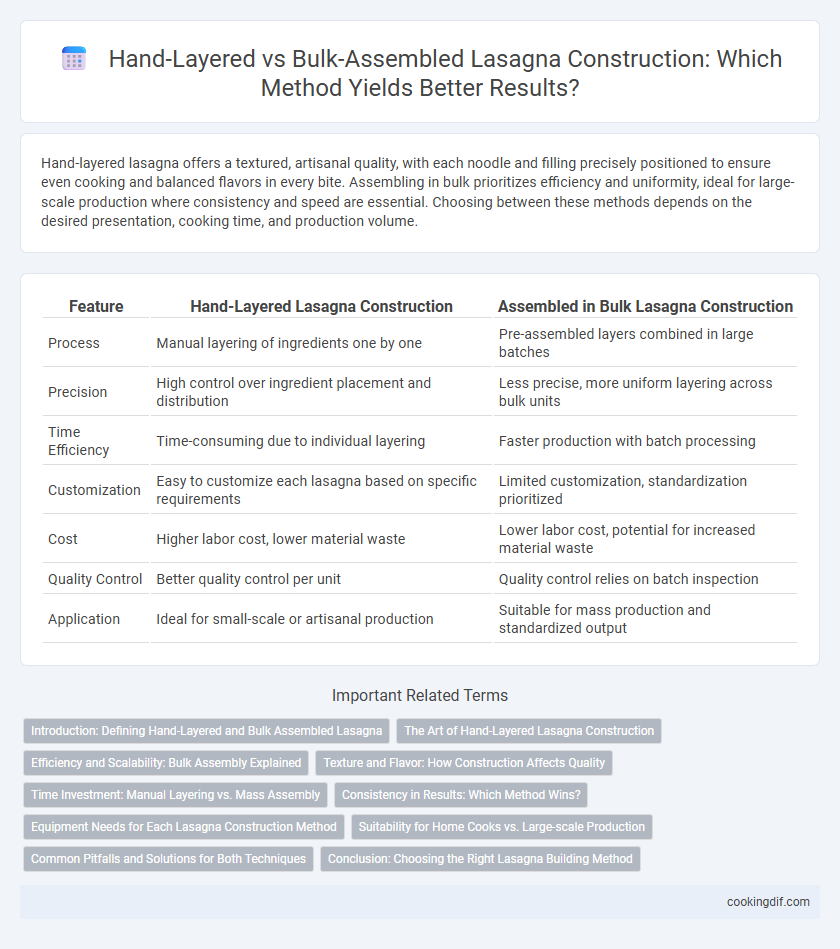

Table of Comparison

| Feature | Hand-Layered Lasagna Construction | Assembled in Bulk Lasagna Construction |

|---|---|---|

| Process | Manual layering of ingredients one by one | Pre-assembled layers combined in large batches |

| Precision | High control over ingredient placement and distribution | Less precise, more uniform layering across bulk units |

| Time Efficiency | Time-consuming due to individual layering | Faster production with batch processing |

| Customization | Easy to customize each lasagna based on specific requirements | Limited customization, standardization prioritized |

| Cost | Higher labor cost, lower material waste | Lower labor cost, potential for increased material waste |

| Quality Control | Better quality control per unit | Quality control relies on batch inspection |

| Application | Ideal for small-scale or artisanal production | Suitable for mass production and standardized output |

Introduction: Defining Hand-Layered and Bulk Assembled Lasagna

Hand-layered lasagna involves placing each noodle, sauce, and cheese layer individually to ensure precise texture and flavor distribution. Bulk assembled lasagna is prepared by mass layering ingredients in large trays for efficiency in volume production. Both methods impact the dish's structural integrity and taste profile, with hand-layering offering greater control over ingredient balance.

The Art of Hand-Layered Lasagna Construction

Hand-layered lasagna involves carefully placing each noodle, sauce, and cheese layer by hand, ensuring precise texture and flavor balance that enhances the overall culinary experience. This method allows for greater control over ingredient distribution, resulting in a more visually appealing and evenly cooked dish. In contrast, bulk assembly often sacrifices this attention to detail, potentially compromising consistency and taste quality.

Efficiency and Scalability: Bulk Assembly Explained

Hand-layered lasagna involves individually placing each pasta sheet and filling, offering precise control over texture and flavor but limiting efficiency due to labor intensity. Bulk assembly leverages pre-prepared components combined in large quantities, significantly enhancing scalability and reducing production time in commercial kitchens. This method enables consistent product quality while optimizing resources, making it ideal for high-volume foodservice operations.

Texture and Flavor: How Construction Affects Quality

Hand-layered lasagna offers distinct texture variations with each layer, enhancing the balance of pasta, sauce, and cheese in every bite, resulting in a richer flavor profile. Assembled in bulk lasagna tends to have more uniform layers, which can lead to a consistent but less complex texture and flavor throughout the dish. The meticulous layering in hand-crafted lasagna allows for better sauce absorption and ingredient integration, ultimately improving overall quality.

Time Investment: Manual Layering vs. Mass Assembly

Hand-layered lasagna requires significant time investment due to the meticulous placement of each pasta sheet, sauce, and filling to achieve an even distribution and authentic texture. Bulk assembly methods drastically reduce preparation time by utilizing pre-portioned ingredients and automated layering techniques, ideal for large-scale production without compromising consistency. Time efficiency in mass assembly supports meeting high demand, while manual layering excels in delivering artisanal quality and precision.

Consistency in Results: Which Method Wins?

Hand-layered lasagna ensures precise ingredient distribution, enhancing texture and flavor consistency in each serving, while bulk assembly may lead to uneven layering and variable taste outcomes across portions. Consistency in results heavily depends on meticulous manual layering, which controls moisture and cooking uniformity better than mass assembly techniques. For restaurants prioritizing consistent quality, hand-layered construction generally outperforms bulk assembly in delivering predictable, high-quality lasagna.

Equipment Needs for Each Lasagna Construction Method

Hand-layered lasagna construction requires minimal, versatile equipment such as large mixing bowls, spatulas, and individual baking trays, allowing precise control over ingredient distribution and layering. In contrast, bulk assembly demands industrial-scale tools including large conveyor belts, automated spreading machines, and high-capacity ovens to handle volume efficiently and ensure uniform consistency. Equipment choice directly influences production speed, portion accuracy, and overall quality in lasagna preparation.

Suitability for Home Cooks vs. Large-scale Production

Hand-layered lasagna offers precise control over ingredient distribution and texture, making it ideal for home cooks seeking customization and freshness. Assembled in bulk lasagnas prioritize efficiency and consistency, suited for large-scale production with standardized portioning and faster preparation times. Home kitchens benefit from hand-layering techniques to tailor flavors, while commercial operations rely on bulk assembly to meet high demand and reduce labor costs.

Common Pitfalls and Solutions for Both Techniques

Hand-layered lasagna allows precise control over ingredient distribution but risks uneven cooking and instability if layers are inconsistent. Bulk assembly speeds preparation, yet can cause soggy textures due to excess moisture and uneven heat penetration. Ensuring even sauce consistency, careful layering, and proper baking temperatures mitigates common issues across both methods.

Conclusion: Choosing the Right Lasagna Building Method

Hand-layered lasagna construction offers precise control over each layer's composition, ensuring optimized soil health and plant growth. Assembled-in-bulk methods prioritize efficiency and can save time but may compromise the fine tuning of ingredient placement. Selecting the right technique depends on balancing labor availability with the desired quality and customization of the garden bed.

Hand-layered vs Assembled in bulk for construction Infographic

cookingdif.com

cookingdif.com