Deglazing enhances flavor extraction in gravy by dissolving browned bits from cookware, creating a richer and more complex taste. Direct mixing blends ingredients without extracting those deep, caramelized flavors, often resulting in a simpler profile. Choosing deglazing over direct mixing significantly boosts the savory depth and aroma of pet gravy.

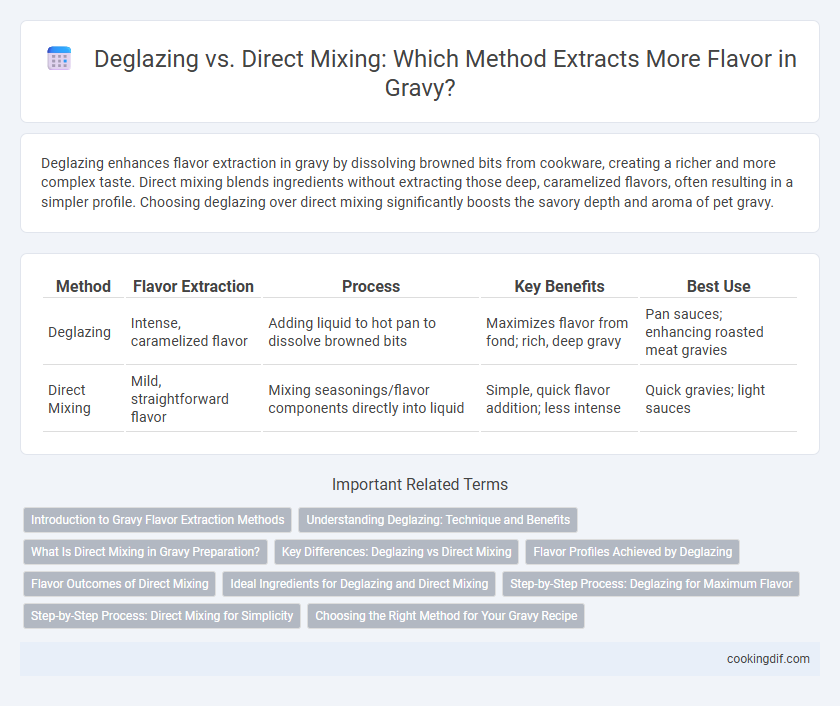

Table of Comparison

| Method | Flavor Extraction | Process | Key Benefits | Best Use |

|---|---|---|---|---|

| Deglazing | Intense, caramelized flavor | Adding liquid to hot pan to dissolve browned bits | Maximizes flavor from fond; rich, deep gravy | Pan sauces; enhancing roasted meat gravies |

| Direct Mixing | Mild, straightforward flavor | Mixing seasonings/flavor components directly into liquid | Simple, quick flavor addition; less intense | Quick gravies; light sauces |

Introduction to Gravy Flavor Extraction Methods

Deglazing enhances gravy flavor by dissolving browned food particles from the pan with liquid, extracting deep, caramelized notes. Direct mixing combines ingredients without pan residue, producing a more straightforward taste profile. Understanding these methods allows cooks to manipulate flavor intensity and complexity in gravy preparation.

Understanding Deglazing: Technique and Benefits

Deglazing involves pouring liquid, typically wine or broth, into a hot pan to dissolve browned food residues, unlocking deep flavors that enhance gravy richness. This technique extracts complex caramelized compounds and prevents burnt tastes, unlike direct mixing which may dilute flavors without integrating the fond. Mastering deglazing ensures gravies achieve a balanced, robust profile by fully capturing the pan's concentrated essence.

What Is Direct Mixing in Gravy Preparation?

Direct mixing in gravy preparation involves combining pan drippings with liquid ingredients without first loosening the browned bits from the pan surface. This method results in a milder flavor profile as it limits the extraction of caramelized compounds that contribute to depth and richness. Comparing direct mixing to deglazing, the latter enhances flavor by dissolving fond with wine, stock, or broth to incorporate concentrated savory elements into the gravy.

Key Differences: Deglazing vs Direct Mixing

Deglazing involves using a liquid, such as wine or broth, to dissolve browned food residues from the pan, enhancing the gravy's depth of flavor through caramelized compounds. Direct mixing combines ingredients without loosening these flavorful bits, often resulting in a less complex taste. The key difference lies in flavor extraction efficiency, with deglazing providing a richer, more intensified gravy by incorporating the pan's fond.

Flavor Profiles Achieved by Deglazing

Deglazing enhances gravy flavor profiles by dissolving browned bits and caramelized residues from the pan, adding a rich, deep umami complexity. The process extracts concentrated savory compounds that direct mixing often misses, resulting in a more robust and layered taste. This technique intensifies the gravy's aroma and mouthfeel, delivering a balanced harmony of sweet, salty, and savory notes.

Flavor Outcomes of Direct Mixing

Direct mixing in gravy preparation preserves the integrity of individual ingredients, resulting in a fresher, more distinct flavor profile compared to deglazing. This method enhances the natural taste of herbs, spices, and base ingredients without the deep caramelized notes produced by deglazing. Flavor outcomes in direct mixing emphasize clarity and brightness, making it ideal for lighter, more delicate gravy varieties.

Ideal Ingredients for Deglazing and Direct Mixing

Ideal ingredients for deglazing include acidic liquids such as wine, vinegar, or citrus juice, which effectively dissolve browned food residue and enhance flavor complexity. Direct mixing works best with creamy or fatty components like butter, cream, or stock, blending smoothly to create a rich, cohesive gravy. Understanding these ingredient roles ensures optimal flavor extraction and texture in your gravy preparation.

Step-by-Step Process: Deglazing for Maximum Flavor

Deglazing involves pouring a liquid such as wine, broth, or vinegar into a hot pan to dissolve browned food particles, creating a rich base for gravy. This process intensifies the flavor by extracting caramelized bits that direct mixing fails to incorporate. Performing deglazing immediately after cooking meat ensures maximum extraction of savory compounds, resulting in a more complex and flavorful gravy.

Step-by-Step Process: Direct Mixing for Simplicity

Direct mixing for flavor extraction involves adding liquid ingredients straight into the pan with cooked meat or vegetables, allowing the fats and browned bits to dissolve and blend seamlessly. This straightforward method skips the need for scraping, gently emulsifying the sauce with minimal effort and reducing overall cooking time. By combining juices, stock, or wine directly, direct mixing enhances depth of flavor while maintaining an uncomplicated preparation process ideal for quick gravies.

Choosing the Right Method for Your Gravy Recipe

Deglazing enhances gravy flavor by dissolving browned food particles and caramelized bits from the pan, intensifying savory depth with wine, broth, or stock. Direct mixing blends pre-cooked ingredients and liquid without the concentrated fond, resulting in a milder, smoother gravy texture. Selecting deglazing is ideal for robust, rich gravies, while direct mixing suits delicate, lightly flavored sauces.

Deglazing vs direct mixing for flavor extraction Infographic

cookingdif.com

cookingdif.com