Steam injection creates a moist oven environment that helps develop a thin, crispy crust with a shiny finish by delaying crust formation and allowing the bread to expand fully. Dutch ovens trap steam released from the dough itself during baking, producing a thick, chewy crust with deep browning and a rustic appearance. Both methods enhance crust texture but differ in moisture control and the resulting crumb structure.

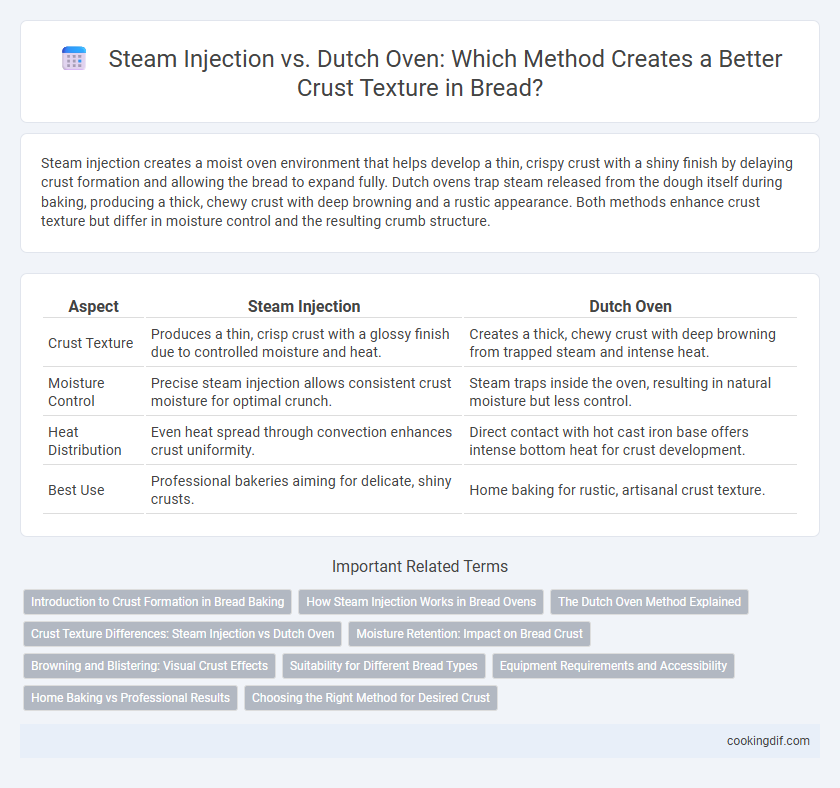

Table of Comparison

| Aspect | Steam Injection | Dutch Oven |

|---|---|---|

| Crust Texture | Produces a thin, crisp crust with a glossy finish due to controlled moisture and heat. | Creates a thick, chewy crust with deep browning from trapped steam and intense heat. |

| Moisture Control | Precise steam injection allows consistent crust moisture for optimal crunch. | Steam traps inside the oven, resulting in natural moisture but less control. |

| Heat Distribution | Even heat spread through convection enhances crust uniformity. | Direct contact with hot cast iron base offers intense bottom heat for crust development. |

| Best Use | Professional bakeries aiming for delicate, shiny crusts. | Home baking for rustic, artisanal crust texture. |

Introduction to Crust Formation in Bread Baking

Steam injection promotes a crisp, thin crust by delaying starch gelatinization and keeping the dough surface moist, which enhances oven spring and caramelization. Dutch ovens create a self-contained steam environment that traps moisture released by the dough, resulting in a thick, chewy crust with a glossy finish. Both methods manipulate moisture retention during baking to optimize crust texture and flavor development.

How Steam Injection Works in Bread Ovens

Steam injection in bread ovens introduces moisture directly into the baking chamber at the start of the baking process, which delays the formation of the crust and allows the bread to expand fully. This moisture creates a glossy, thin, and crackly crust by gelatinizing the starches on the bread's surface and promoting Maillard reaction. Compared to Dutch ovens, steam injection offers more precise control over humidity levels, resulting in consistent crust texture and enhanced oven spring.

The Dutch Oven Method Explained

The Dutch oven method creates a thick, crispy crust by trapping steam released from the dough during baking, which mimics professional steam injection ovens. This enclosed environment promotes even heat distribution and moisture retention, resulting in a golden-brown, crackly exterior. Compared to steam injection, using a Dutch oven is a simple, accessible technique for achieving artisan-quality crust texture at home.

Crust Texture Differences: Steam Injection vs Dutch Oven

Steam injection in bread baking produces a thin, glossy crust with a delicate crunch by trapping moisture early in the baking process, allowing optimal oven spring and crust caramelization. Dutch oven baking creates a thicker, chewier crust due to its enclosed environment that retains more steam and distributes heat evenly, resulting in a crust with greater depth and contrast between crisp exterior and tender interior. Both methods enhance crust texture but differ in moisture retention and heat circulation, impacting the final bread's mouthfeel and visual appeal.

Moisture Retention: Impact on Bread Crust

Steam injection creates a moist oven environment that delays crust formation, allowing the bread to expand fully and develop a thinner, crisper crust with enhanced glossiness. Dutch oven baking traps steam released from the dough itself, promoting moisture retention and resulting in a thicker, chewier crust with a rustic texture. Both methods optimize moisture around the dough during initial baking stages, significantly influencing crust texture and achieving desired moisture levels for artisanal bread.

Browning and Blistering: Visual Crust Effects

Steam injection in ovens promotes intense Browning and creates a glossy, blistered crust by maintaining high humidity during the initial baking phase, which delays crust formation allowing enhanced Maillard reactions. Dutch oven baking traps natural steam released by the dough, resulting in a thick, crisp crust with moderate blistering and rich, caramelized color. Both methods intensify crust texture, but steam injection typically yields more uniform Browning, while Dutch ovens offer a rustic, artisan appearance with distinctive crust blistering.

Suitability for Different Bread Types

Steam injection creates a moist environment ideal for artisan breads like baguettes and sourdough, promoting a crisp, blistered crust. Dutch ovens retain steam naturally, making them perfect for rustic loaves such as boule or country bread that require even heat and consistent humidity. Choosing between steam injection and a Dutch oven depends on the desired crust thickness, texture, and the bread type's baking requirements.

Equipment Requirements and Accessibility

Steam injection ovens require specialized commercial equipment that delivers controlled bursts of steam to create a crisp, shiny crust, making them less accessible for home bakers due to cost and size. Dutch ovens offer an affordable and simple alternative, providing a sealed environment that traps moisture from the dough itself, producing a comparable crust texture without the need for advanced hardware. Home bakers benefit from the Dutch oven's portability and accessibility, while steam injection remains ideal for professional bakeries prioritizing precise crust control.

Home Baking vs Professional Results

Steam injection ovens create a humid environment that promotes a glossy, blistered crust favored in professional baking, while Dutch ovens trap steam from the dough's own moisture, yielding a thick, chewy crust ideal for home bakers. Professional steam injection systems allow precise control over humidity and temperature, resulting in consistent crust texture, whereas Dutch ovens rely on preheating and manual steam retention, offering an accessible yet effective method for artisanal bread crust development. Home bakers seeking professional-quality crust can mimic steam injection effects by using cast iron Dutch ovens to enhance oven spring and crust caramelization without specialized equipment.

Choosing the Right Method for Desired Crust

Steam injection creates a moist environment that promotes a glossy, crisp crust by allowing the dough to expand fully before the crust sets. Dutch ovens trap steam released from the dough itself, producing a thick, crackly crust with artisan-style blisters. Selecting steam injection is ideal for bakery consistency and shine, while a Dutch oven best suits rustic, deeply caramelized crust textures.

Steam Injection vs Dutch Oven for crust texture Infographic

cookingdif.com

cookingdif.com