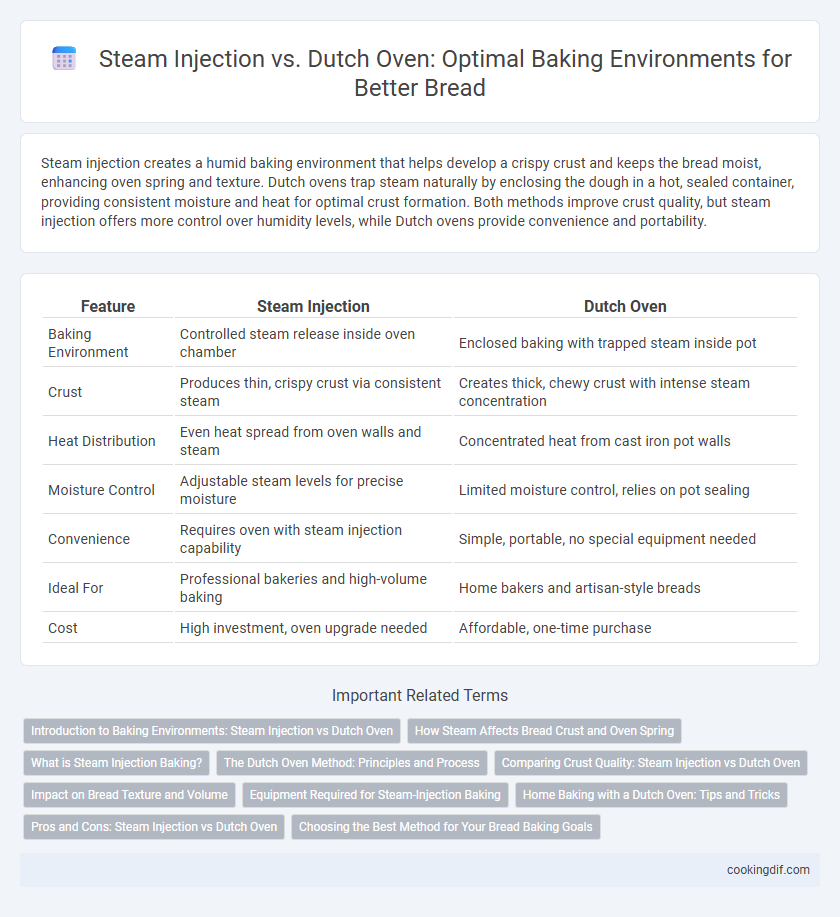

Steam injection creates a humid baking environment that helps develop a crispy crust and keeps the bread moist, enhancing oven spring and texture. Dutch ovens trap steam naturally by enclosing the dough in a hot, sealed container, providing consistent moisture and heat for optimal crust formation. Both methods improve crust quality, but steam injection offers more control over humidity levels, while Dutch ovens provide convenience and portability.

Table of Comparison

| Feature | Steam Injection | Dutch Oven |

|---|---|---|

| Baking Environment | Controlled steam release inside oven chamber | Enclosed baking with trapped steam inside pot |

| Crust | Produces thin, crispy crust via consistent steam | Creates thick, chewy crust with intense steam concentration |

| Heat Distribution | Even heat spread from oven walls and steam | Concentrated heat from cast iron pot walls |

| Moisture Control | Adjustable steam levels for precise moisture | Limited moisture control, relies on pot sealing |

| Convenience | Requires oven with steam injection capability | Simple, portable, no special equipment needed |

| Ideal For | Professional bakeries and high-volume baking | Home bakers and artisan-style breads |

| Cost | High investment, oven upgrade needed | Affordable, one-time purchase |

Introduction to Baking Environments: Steam Injection vs Dutch Oven

Steam injection and Dutch ovens create distinct baking environments that significantly affect bread crust and crumb development. Steam injection ovens introduce controlled moisture during the initial baking phase, promoting a glossy, crisp crust and better oven spring by gelatinizing the dough surface. Dutch ovens trap natural steam from the dough, creating a humid environment that enhances crust texture and volume, making them ideal for artisan-style bread without specialized equipment.

How Steam Affects Bread Crust and Oven Spring

Steam injection during baking creates a humid environment that delays crust formation, allowing maximal oven spring by enabling the dough to expand fully before the crust hardens. The moisture also promotes a glossy, crisp crust by gelatinizing starches on the bread surface. In contrast, a Dutch oven traps natural steam released by the dough, offering a similar effect but with less precise humidity control compared to professional steam injection systems.

What is Steam Injection Baking?

Steam injection baking involves introducing controlled steam into the oven cavity during the initial phase of baking to create a humid environment that promotes crust development and oven spring. This technique enhances the Maillard reaction, resulting in a glossy, crisp crust while maintaining a tender crumb inside the bread. Compared to Dutch oven baking, which traps steam naturally in a confined space, steam injection allows for precise humidity control and is commonly used in professional bakeries for consistent high-volume production.

The Dutch Oven Method: Principles and Process

The Dutch oven method for baking bread creates a sealed, humid environment that mimics professional steam-injected ovens by trapping moisture released from the dough, essential for achieving a crispy crust and well-developed oven spring. Preheating the Dutch oven ensures a consistent, intense heat transfer, while covering it during the initial baking phase retains steam, promoting optimal crust formation and crumb structure. Removing the lid midway allows the crust to brown evenly, producing artisan-quality bread with a tender interior and crackling exterior.

Comparing Crust Quality: Steam Injection vs Dutch Oven

Steam injection ovens create a controlled environment with consistent moisture levels, producing a glossy, thin, and crackly crust ideal for artisan bread. Dutch ovens trap steam naturally by sealing in moisture released during baking, resulting in a thicker, chewier crust with rich browning and caramelization. While both methods enhance crust quality, steam injection offers precision and uniformity, whereas Dutch ovens provide rustic texture and depth in crust development.

Impact on Bread Texture and Volume

Steam injection creates a humid baking environment that promotes a crisp, glossy crust and allows the bread to expand fully, resulting in a higher volume and open crumb structure. Dutch ovens trap steam released from the dough itself, producing similar crust characteristics but often yield slightly denser texture due to limited steam compared to commercial steam injection. The controlled steam in steam injection ovens enhances oven spring and crust development more effectively, significantly impacting texture and loaf size.

Equipment Required for Steam-Injection Baking

Steam injection baking requires specialized ovens equipped with built-in steam generators, ensuring precise control of humidity and temperature for optimal crust development. Unlike Dutch ovens, which are portable and rely on trapping steam inside a closed pot, steam-injection ovens demand professional-grade equipment often found in commercial bakeries. This setup enables consistent steam release during the baking process, improving oven spring and crust texture in artisan bread.

Home Baking with a Dutch Oven: Tips and Tricks

Using a Dutch oven for home baking creates a sealed environment that traps steam released from the dough, promoting a crispy crust and moist crumb without the need for external steam injection. Preheating the Dutch oven ensures even heat distribution and better oven spring, while removing the lid halfway through baking prevents excess moisture retention. Enhancing the bread's texture and flavor at home requires minimal equipment but precise timing to mimic professional steam-injected ovens effectively.

Pros and Cons: Steam Injection vs Dutch Oven

Steam injection ovens provide precise humidity control, resulting in consistently crisp crusts and well-developed oven spring, ideal for commercial and artisan bakers. Dutch ovens excel at retaining heat and moisture within a compact environment, producing rustic loaves with a crunchy crust and tender crumb, but require manual handling and limited batch sizes. Steam injection offers automation and scalability, whereas Dutch ovens prioritize simplicity and traditional baking methods, each with distinct advantages depending on production needs and desired bread characteristics.

Choosing the Best Method for Your Bread Baking Goals

Steam injection creates a humid baking environment by introducing vapor directly into the oven, enhancing crust development and oven spring for artisan-style breads. Dutch ovens trap moisture from the dough, simulating steam effects and producing a crisp crust with improved rise in home baking setups. Selecting between steam injection and Dutch oven methods depends on your baking goals, oven type, and desired crust texture, with steam injection ideal for consistent professional results and Dutch ovens suited for rustic, small-batch loaves.

Steam Injection vs Dutch Oven for baking environment Infographic

cookingdif.com

cookingdif.com