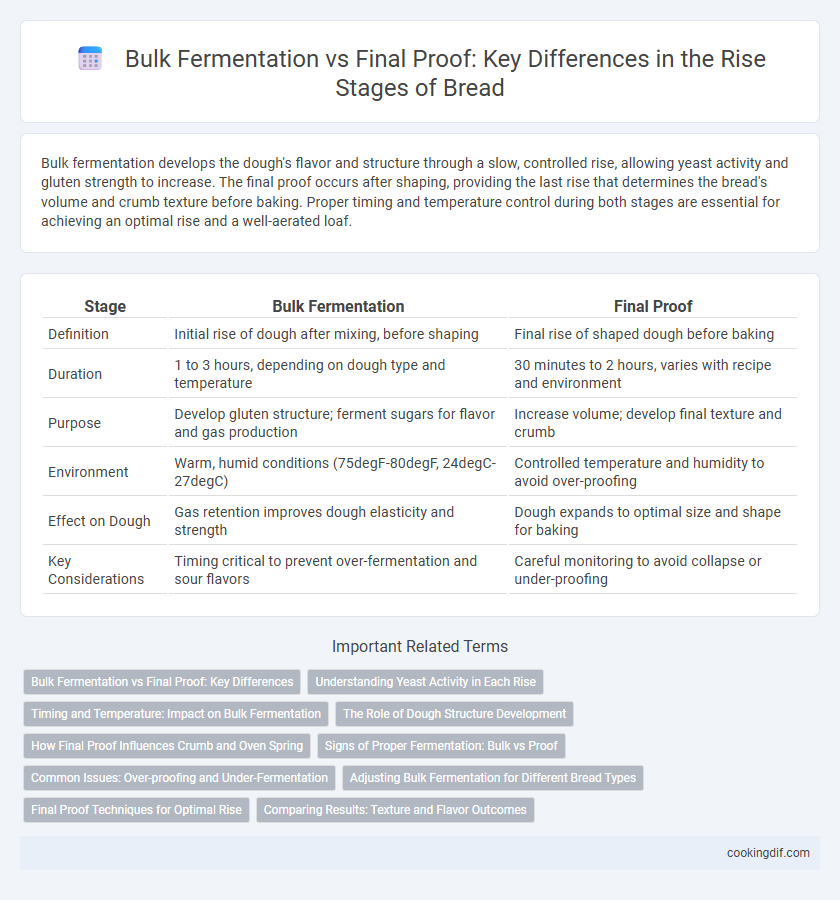

Bulk fermentation develops the dough's flavor and structure through a slow, controlled rise, allowing yeast activity and gluten strength to increase. The final proof occurs after shaping, providing the last rise that determines the bread's volume and crumb texture before baking. Proper timing and temperature control during both stages are essential for achieving an optimal rise and a well-aerated loaf.

Table of Comparison

| Stage | Bulk Fermentation | Final Proof |

|---|---|---|

| Definition | Initial rise of dough after mixing, before shaping | Final rise of shaped dough before baking |

| Duration | 1 to 3 hours, depending on dough type and temperature | 30 minutes to 2 hours, varies with recipe and environment |

| Purpose | Develop gluten structure; ferment sugars for flavor and gas production | Increase volume; develop final texture and crumb |

| Environment | Warm, humid conditions (75degF-80degF, 24degC-27degC) | Controlled temperature and humidity to avoid over-proofing |

| Effect on Dough | Gas retention improves dough elasticity and strength | Dough expands to optimal size and shape for baking |

| Key Considerations | Timing critical to prevent over-fermentation and sour flavors | Careful monitoring to avoid collapse or under-proofing |

Bulk Fermentation vs Final Proof: Key Differences

Bulk fermentation is the initial rise stage where yeast actively produces carbon dioxide, causing the entire dough mass to expand and develop flavor complexity. Final proof occurs after shaping, allowing the dough pieces to rise individually, refining their structure and ensuring optimal oven spring. Key differences include the timing in the baking process, with bulk fermentation focusing on overall dough development and final proof enhancing shape and volume before baking.

Understanding Yeast Activity in Each Rise

During bulk fermentation, yeast actively consumes sugars, producing carbon dioxide and alcohol, which causes the dough to expand and develop flavor and gluten structure. In the final proof, yeast activity slows as the dough reaches its maximum rise, allowing gas bubbles to stabilize without overproofing, ensuring optimal texture. Monitoring yeast activity in each stage is crucial for controlling dough rise and achieving the desired bread crumb and volume.

Timing and Temperature: Impact on Bulk Fermentation

Bulk fermentation, occurring at 75-78degF (24-26degC), typically lasts 1-3 hours depending on dough hydration and yeast activity, allowing yeast to develop flavor and structure by breaking down starches. Temperature during this stage directly influences fermentation speed and gas production, impacting the dough's rise and gluten strength. In contrast, the final proof, conducted at slightly cooler temperatures around 70-75degF (21-24degC) and shorter duration, primarily focuses on dough expansion and fine-tuning texture before baking.

The Role of Dough Structure Development

Bulk fermentation plays a crucial role in developing dough structure by allowing yeast activity to produce gas and enzymes to strengthen the gluten network, enhancing dough elasticity and stability. During this stage, the dough becomes more extensible, which sets the foundation for a well-risen loaf. The final proof further refines dough structure by expanding the gas cells formed earlier, ensuring optimal volume and crumb texture before baking.

How Final Proof Influences Crumb and Oven Spring

Final proof significantly impacts bread crumb texture by allowing yeast activity to create gas bubbles that define the crumb's openness and softness. Properly timed final proof enhances oven spring, which is the rapid expansion in the oven, resulting in a lighter, airier loaf with a crispy crust. Underproofed dough produces a dense crumb and limited oven spring, while overproofed dough may collapse, leading to a flat loaf and poor crumb structure.

Signs of Proper Fermentation: Bulk vs Proof

During bulk fermentation, proper fermentation is indicated by dough doubling in size, developing a smooth surface, and showing visible gas bubbles throughout the mass. Signs of proper final proof include the dough rising further with a light, airy texture, slight doming on the surface, and a gentle spring-back when poked. Monitoring these distinct stages ensures optimal gluten development and yeast activity for the best bread rise.

Common Issues: Over-proofing and Under-Fermentation

Over-proofing during bulk fermentation causes dough to become excessively airy, resulting in a weakened gluten structure and a dense, flat loaf after baking. Under-fermentation at this stage leads to insufficient gas production, producing a tight, dense crumb lacking in flavor development. During the final proof, over-proofing yields collapsed dough and poor oven spring, while under-proofing restricts rise and results in a heavy texture.

Adjusting Bulk Fermentation for Different Bread Types

Bulk fermentation duration varies significantly depending on bread type, with lean doughs typically requiring longer fermentation to develop complex flavors, while enriched doughs need shorter times to prevent overproofing. Adjusting bulk fermentation involves monitoring dough temperature, hydration, and yeast activity to optimize gluten structure and dough rise before shaping. Proper control during bulk fermentation enhances crumb texture and oven spring, setting a critical foundation for the final proof stage.

Final Proof Techniques for Optimal Rise

Final proof techniques critically influence the bread's rise, texture, and crumb structure by allowing yeast activity to develop flavor and gas retention. Employing proper temperature control (around 75-80degF) and humidity levels during final proof prevents over-proofing, ensuring optimal dough expansion without collapse. Using techniques such as bench resting, shaping with tension, and covering dough to retain moisture enhances gluten strength and improves oven spring during baking.

Comparing Results: Texture and Flavor Outcomes

Bulk fermentation enhances gluten development and gas retention, resulting in a chewier texture and more complex, tangy flavors due to prolonged yeast activity. Final proof primarily impacts surface rise and crumb softness, producing a lighter texture with a subtler flavor profile. Balancing bulk fermentation and final proof times is crucial for achieving the desired combination of crust crispness, crumb structure, and flavor depth in artisanal bread.

Bulk fermentation vs Final proof for rise stage Infographic

cookingdif.com

cookingdif.com