Wet-aging beef roast involves sealing the meat in vacuum-packed bags, allowing it to retain moisture and develop a tender texture with a milder flavor. Dry-aging beef roast exposes the meat to controlled air in a refrigerated environment, which enhances the beef's flavor profile by concentrating its taste and creating a firmer texture. Choosing between wet-aging and dry-aging depends on whether you prefer a juicier roast with subtle flavors or a more intense, robust beef experience.

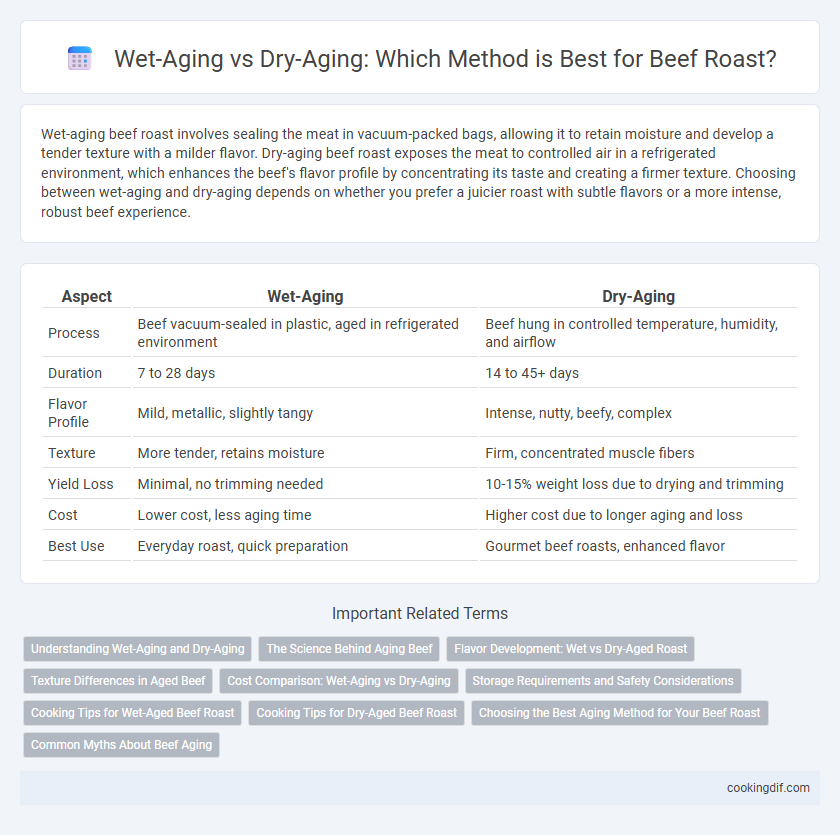

Table of Comparison

| Aspect | Wet-Aging | Dry-Aging |

|---|---|---|

| Process | Beef vacuum-sealed in plastic, aged in refrigerated environment | Beef hung in controlled temperature, humidity, and airflow |

| Duration | 7 to 28 days | 14 to 45+ days |

| Flavor Profile | Mild, metallic, slightly tangy | Intense, nutty, beefy, complex |

| Texture | More tender, retains moisture | Firm, concentrated muscle fibers |

| Yield Loss | Minimal, no trimming needed | 10-15% weight loss due to drying and trimming |

| Cost | Lower cost, less aging time | Higher cost due to longer aging and loss |

| Best Use | Everyday roast, quick preparation | Gourmet beef roasts, enhanced flavor |

Understanding Wet-Aging and Dry-Aging

Wet-aging involves sealing beef roast in vacuum-packed bags to retain moisture and enhance tenderness through enzymatic breakdown, typically lasting 7 to 28 days. Dry-aging exposes the beef to controlled temperature and humidity, concentrating flavor and developing a firmer texture by allowing natural enzymes to break down muscle fibers over 14 to 60 days. Understanding these processes helps optimize beef roast quality by balancing tenderness, flavor intensity, and moisture retention.

The Science Behind Aging Beef

Wet-aging beef roast involves vacuum-sealing the meat to retain moisture and promote enzymatic breakdown, resulting in a tender texture within a shorter period. Dry-aging exposes the beef to controlled air circulation and humidity, causing moisture evaporation and intense flavor concentration through natural enzymatic and microbial processes. Both methods rely on enzymatic activity to break down muscle fibers, but dry-aging enhances flavor development more significantly due to moisture loss and surface mold formation.

Flavor Development: Wet vs Dry-Aged Roast

Wet-aging beef roast enhances flavor by retaining moisture, resulting in a tender, slightly metallic taste due to lactic acid buildup during vacuum-sealed aging. Dry-aging intensifies flavor through controlled dehydration and enzymatic breakdown, creating a richer, nuttier, and more concentrated beef profile with a firmer texture. Flavor development in dry-aged roast is generally preferred by connoisseurs seeking depth and complexity compared to the milder, juicier characteristics of wet-aged beef.

Texture Differences in Aged Beef

Wet-aging beef roast involves sealing the meat in vacuum bags, preserving moisture and resulting in a more tender but slightly softer texture. Dry-aging exposes beef to controlled air and temperature, allowing enzymatic breakdown and moisture evaporation, which intensifies flavor and produces a firmer, chewier texture with a concentrated beefy taste. The textural difference is marked by wet-aged beef's juiciness and softness compared to dry-aged beef's robust, dense bite and complex mouthfeel.

Cost Comparison: Wet-Aging vs Dry-Aging

Wet-aging beef roast is generally more cost-effective due to lower storage requirements and reduced weight loss from moisture evaporation. Dry-aging demands specialized controlled environments, higher energy consumption, and results in trim loss, increasing overall expenses. Consequently, wet-aging offers a more economical option for budget-conscious consumers without significantly compromising flavor.

Storage Requirements and Safety Considerations

Wet-aging beef roast requires vacuum-sealed packaging stored at temperatures between 32degF and 34degF to prevent bacterial growth, ensuring a safe environment through controlled moisture retention. Dry-aging demands precise humidity levels around 80-85% and temperatures near 34degF, with adequate air circulation to avoid spoilage while developing deeper flavor profiles. Both methods rely on strict sanitation protocols and temperature monitoring to maintain safety and quality throughout the aging process.

Cooking Tips for Wet-Aged Beef Roast

Wet-aged beef roast retains more moisture, resulting in a tender and juicy texture ideal for slow roasting at low temperatures between 275degF to 325degF. Using a meat thermometer ensures the internal temperature reaches 135degF for medium-rare doneness, preserving optimal flavor and tenderness. Resting the roast for at least 15 minutes before carving allows juices to redistribute, enhancing succulence and overall eating experience.

Cooking Tips for Dry-Aged Beef Roast

Dry-aged beef roast requires careful cooking at a lower temperature to preserve its rich, concentrated flavor and tender texture. Allow the roast to reach room temperature before cooking and use a meat thermometer to achieve precise doneness, targeting medium-rare at 130-135degF. Rest the roast for at least 20 minutes after cooking to redistribute juices and enhance succulence.

Choosing the Best Aging Method for Your Beef Roast

Wet-aging preserves moisture by storing vacuum-sealed beef in a controlled refrigerated environment, resulting in a tender, juicy roast with a milder flavor. Dry-aging involves hanging beef in a temperature- and humidity-controlled room, intensifying flavor through natural enzymatic breakdown and moisture evaporation, producing a concentration of beefy taste and firmer texture. Selecting the ideal aging method depends on whether you prioritize enhanced tenderness and moisture retention or flavorful richness and a robust roast profile.

Common Myths About Beef Aging

Wet-aging preserves beef in vacuum-sealed packaging, retaining moisture and producing a milder flavor, while dry-aging involves hanging meat in controlled environments, intensifying flavor and tenderizing the roast through natural enzymatic processes. Common myths suggest wet-aged beef lacks flavor or that dry-aging always results in superior tenderness, but scientific evidence shows that flavor preferences are subjective and tenderness depends on specific aging conditions and meat quality. Both methods effectively enhance beef roast, and consumer choice often relies on desired taste profiles and budget considerations rather than aging myths.

Wet-aging vs Dry-aging for beef roast Infographic

cookingdif.com

cookingdif.com