Traditional extruders produce pasta with a smooth, uniform texture due to the use of Teflon-coated dies, whereas bronze dies create a rougher surface that better holds sauce. Bronze die pasta has a slightly coarse texture, enhancing the overall eating experience by allowing sauces to cling more effectively. Choosing between the two affects both the mouthfeel and how well the pasta absorbs flavors during cooking.

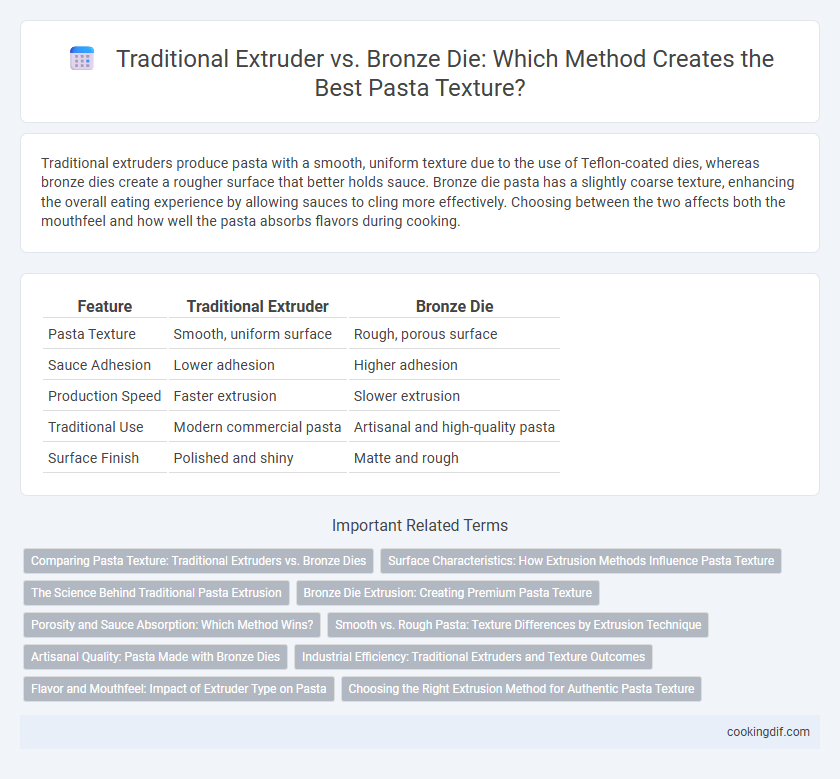

Table of Comparison

| Feature | Traditional Extruder | Bronze Die |

|---|---|---|

| Pasta Texture | Smooth, uniform surface | Rough, porous surface |

| Sauce Adhesion | Lower adhesion | Higher adhesion |

| Production Speed | Faster extrusion | Slower extrusion |

| Traditional Use | Modern commercial pasta | Artisanal and high-quality pasta |

| Surface Finish | Polished and shiny | Matte and rough |

Comparing Pasta Texture: Traditional Extruders vs. Bronze Dies

Traditional extruders produce pasta with a smoother, more uniform texture due to their polished steel dies, which result in less sauce adherence. Bronze dies create a rougher, more porous surface that enhances sauce cling and contributes to a more authentic, artisanal mouthfeel. Comparing pasta texture, bronze die pasta is often preferred for its rustic appearance and superior sauce retention, while traditional extruder pasta appeals with its consistent shape and tenderness.

Surface Characteristics: How Extrusion Methods Influence Pasta Texture

Traditional extruders using bronze dies produce pasta with a rougher, more porous surface, enhancing sauce adherence and creating a rustic texture favored in authentic Italian cuisine. In contrast, Teflon-coated or non-stick dies in modern extruders yield smoother pasta surfaces, resulting in a silkier mouthfeel but reduced sauce absorption. The surface characteristics generated by the extrusion method significantly impact the overall sensory experience and the pasta's ability to retain flavors.

The Science Behind Traditional Pasta Extrusion

Traditional pasta extrusion relies on bronze dies that create a rough, porous surface on the pasta, enhancing sauce adhesion through increased surface area. The bronze die's microscopic grooves produce a unique texture compared to the smoother finish of Teflon-coated extruders, positively influencing the pasta's ability to hold flavor. Scientific analysis shows that this rough texture modifies protein structure and moisture absorption, contributing to better sauce retention and an authentic mouthfeel.

Bronze Die Extrusion: Creating Premium Pasta Texture

Bronze die extrusion imparts a rough, porous surface to pasta, enhancing its ability to hold sauces and delivering authentic texture reminiscent of artisanal pasta. Unlike traditional extruders that use Teflon-coated dies producing smooth surfaces, bronze dies slow the pasta's passage through the mold, resulting in a denser, chewier bite favored by chefs and consumers seeking premium quality. This method aligns with premium pasta production by offering superior sauce adhesion and a rustic, handcrafted appearance.

Porosity and Sauce Absorption: Which Method Wins?

Bronze die pasta creates a rougher surface with higher porosity compared to traditional extruder methods, enhancing sauce absorption significantly. The increased porosity allows sauces to cling better, resulting in a more flavorful bite. Traditional extruder pasta tends to have a smoother texture, which may lead to less effective sauce retention.

Smooth vs. Rough Pasta: Texture Differences by Extrusion Technique

Traditional extruders using bronze dies create pasta with a rougher surface, allowing sauces to cling better and enhancing flavor absorption. In contrast, pasta produced with Teflon-coated smooth dies has a sleeker texture, resulting in a more delicate mouthfeel but less sauce retention. The choice between bronze and smooth dies significantly influences the final pasta texture and culinary experience.

Artisanal Quality: Pasta Made with Bronze Dies

Pasta made using bronze dies features a rougher, more porous texture that allows sauces to cling better, enhancing the overall flavor experience. This artisanal technique, rooted in traditional Italian pasta-making, contrasts with modern extruders that produce smoother surfaces. The durability and material composition of bronze dies contribute significantly to the distinct, authentic texture highly sought after by chefs and food enthusiasts.

Industrial Efficiency: Traditional Extruders and Texture Outcomes

Traditional extruders with Teflon-coated dies enhance industrial efficiency by reducing pasta sticking and facilitating faster production cycles. Bronze dies, preferred for artisanal pasta, impart a rougher texture that improves sauce adhesion but may slow down manufacturing due to increased resistance and wear. Industrial operations prioritize traditional extruders for consistent output and lower maintenance costs, balancing texture quality with high-volume demands.

Flavor and Mouthfeel: Impact of Extruder Type on Pasta

Traditional extruders produce pasta with a smoother surface that results in a tender mouthfeel but may lack the robust texture associated with artisanal pasta. Bronze die extrusion creates a rougher surface, enhancing sauce adhesion and delivering a more al dente bite with intensified flavor absorption. The choice between these methods significantly influences pasta's sensory experience, balancing texture and taste complexity.

Choosing the Right Extrusion Method for Authentic Pasta Texture

Traditional extruders use Teflon-coated dies that produce smooth pasta surfaces, while bronze dies create rougher textures essential for holding sauces better. Opting for bronze die extrusion enhances the pasta's ability to absorb and cling to rich Italian sauces, delivering a more authentic dining experience. Selecting the right extrusion method depends on desired texture, with bronze die pasta preferred by chefs aiming for traditional, rustic qualities.

Traditional extruder vs bronze die for pasta texture Infographic

cookingdif.com

cookingdif.com