Bronze die pasta offers a rougher surface texture that better holds sauces, enhancing flavor absorption and providing a traditional, artisanal quality. Teflon die pasta, with its smooth finish, results in a slicker texture that cooks faster but may not cling to sauces as effectively. Choosing between bronze and teflon dies impacts pasta mouthfeel and sauce compatibility, influencing the overall dining experience.

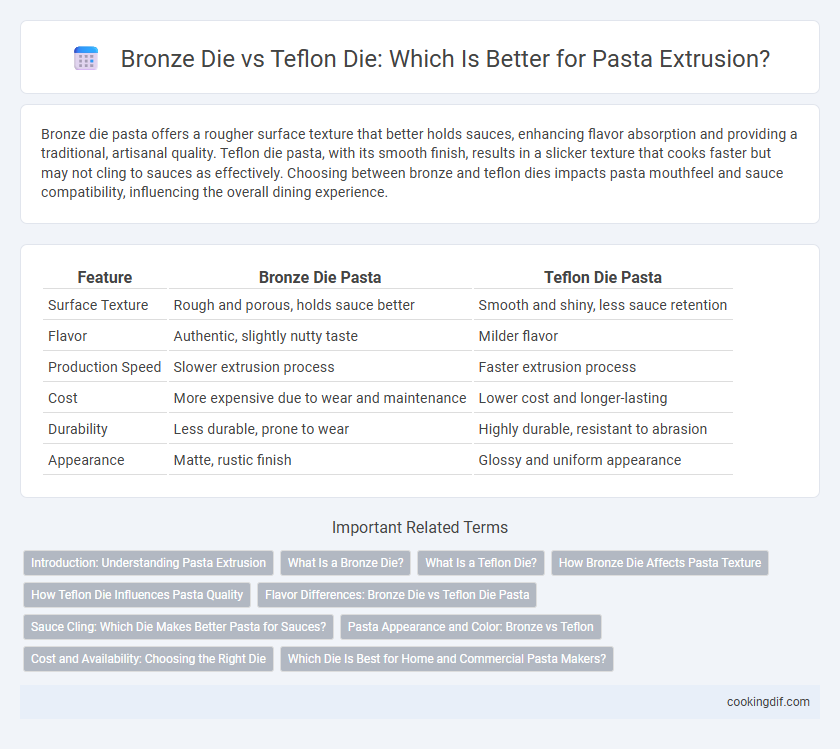

Table of Comparison

| Feature | Bronze Die Pasta | Teflon Die Pasta |

|---|---|---|

| Surface Texture | Rough and porous, holds sauce better | Smooth and shiny, less sauce retention |

| Flavor | Authentic, slightly nutty taste | Milder flavor |

| Production Speed | Slower extrusion process | Faster extrusion process |

| Cost | More expensive due to wear and maintenance | Lower cost and longer-lasting |

| Durability | Less durable, prone to wear | Highly durable, resistant to abrasion |

| Appearance | Matte, rustic finish | Glossy and uniform appearance |

Introduction: Understanding Pasta Extrusion

Bronze die pasta extrusion creates a rougher surface texture that enhances sauce adhesion, resulting in a more flavorful dish, while Teflon die extrusion produces smoother pasta with a shiny appearance. Bronze dies are preferred in artisanal pasta production due to their ability to retain traditional texture and promote authentic sauce absorption. The choice between bronze and Teflon dies significantly impacts the pasta's mouthfeel and overall culinary experience.

What Is a Bronze Die?

A bronze die is a traditional tool used in pasta extrusion, made from bronze to create rough-textured pasta surfaces that help sauce adhere better. Bronze dies produce pasta with a porous, slightly coarse finish, enhancing flavor absorption and improving the overall eating experience. Unlike the smooth finish from Teflon dies, bronze dies contribute to the authentic texture and artisanal quality of premium pasta products.

What Is a Teflon Die?

A Teflon die is a pasta extrusion tool coated with polytetrafluoroethylene (PTFE) that provides a smooth surface, reducing friction during dough extrusion. Unlike bronze dies that impart a rough texture to pasta for better sauce adherence, Teflon dies produce pasta with a sleek, uniform finish prized for delicate shapes. The non-stick properties of Teflon dies enhance production efficiency by minimizing dough residue and easing cleaning processes.

How Bronze Die Affects Pasta Texture

Bronze die pasta extrusion creates a rougher surface texture, allowing sauces to cling better, enhancing flavor absorption. This rough texture results from the die's abrasive nature, which imparts microscopic grooves on the pasta surface. In contrast, Teflon dies produce smoother pasta, offering a different mouthfeel and sauce interaction.

How Teflon Die Influences Pasta Quality

Teflon die in pasta extrusion enhances surface smoothness and reduces sticking, resulting in a more uniform shape and consistent cooking texture. Unlike bronze dies, Teflon dies produce pasta with a less porous surface, which can affect sauce adherence and overall flavor absorption. The non-stick properties of Teflon also contribute to faster production but may yield pasta with a slightly different mouthfeel compared to traditional bronze-extruded pasta.

Flavor Differences: Bronze Die vs Teflon Die Pasta

Bronze die pasta has a rougher texture that allows sauces to cling better, enhancing flavor absorption and creating a more robust taste experience. Teflon die pasta is smoother and less porous, resulting in a cleaner appearance but a less intense sauce adherence. Many chefs prefer bronze die pasta for its traditional taste profile and superior sauce integration.

Sauce Cling: Which Die Makes Better Pasta for Sauces?

Bronze dies create pasta with a rougher surface texture, enhancing sauce adherence and resulting in better flavor integration. In contrast, Teflon dies produce smoother pasta, which tends to repel sauce and diminish overall sauce cling. Pasta extruded through bronze dies is preferred for dishes requiring rich, thick sauces due to its superior sauce retention.

Pasta Appearance and Color: Bronze vs Teflon

Pasta extruded through bronze dies has a rougher texture and a slightly darker, more golden hue, enhancing sauce adherence and visual appeal. In contrast, pasta produced with Teflon dies is smoother, glossier, and typically paler in color, which may result in a less rustic appearance. The choice of die material significantly influences the final pasta's surface quality and color intensity, affecting consumer perception and culinary experience.

Cost and Availability: Choosing the Right Die

Bronze dies for pasta extrusion typically cost more than Teflon dies due to their durable material and traditional manufacturing process, making them less available and often reserved for artisanal pasta production. Teflon dies are more widely available and budget-friendly, offering ease of use and lower initial investment, which benefits large-scale or commercial pasta makers. Considering cost and availability, Teflon dies suit mass production needs, while bronze dies justify their expense with unique texture and quality preferred by specialty pasta producers.

Which Die Is Best for Home and Commercial Pasta Makers?

Bronze dies produce pasta with a rougher texture, allowing sauces to cling better, making them ideal for artisanal quality in both home and commercial pasta making. Teflon dies offer a smoother surface for faster extrusion and easier cleaning, preferred in commercial settings where consistency and speed are essential. Choosing between bronze and teflon dies depends on whether texture and sauce adherence or efficiency and maintenance are prioritized in pasta production.

bronze die vs teflon die for pasta extrusion Infographic

cookingdif.com

cookingdif.com