Bronze-cut pasta dough is extruded through bronze dies, giving the pasta a rougher, porous surface that better holds onto sauces, enhancing flavor and texture. Teflon-cut pasta, created with non-stick Teflon dies, results in a smoother, shinier finish that cooks more quickly but may not capture sauces as effectively. Choosing bronze-cut pasta is ideal for traditional recipes where sauce adherence is crucial, while Teflon-cut pasta suits lighter, delicate preparations.

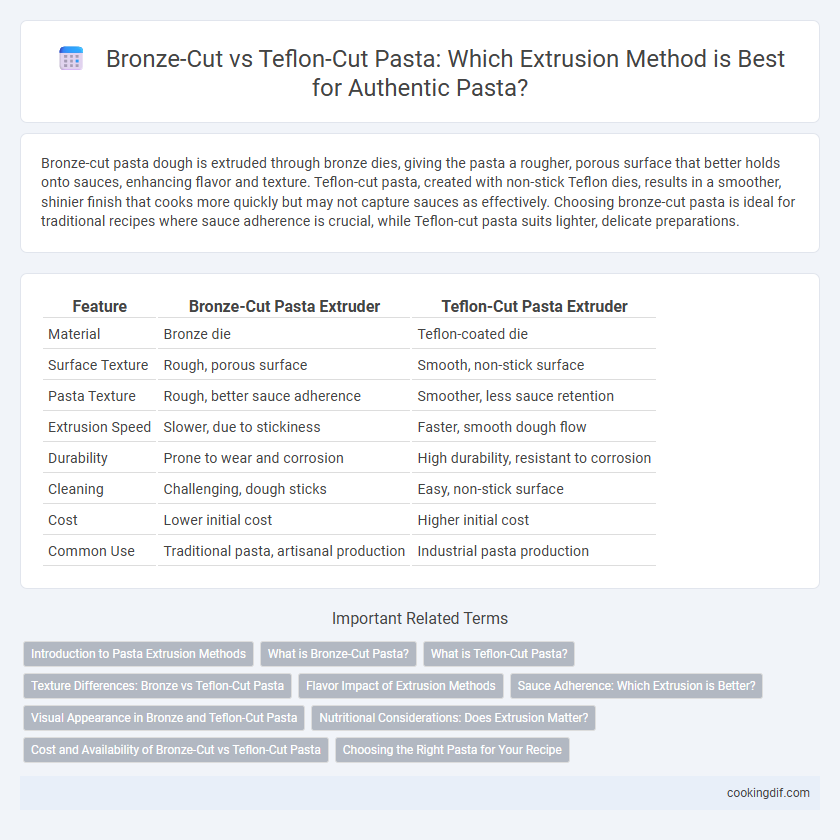

Table of Comparison

| Feature | Bronze-Cut Pasta Extruder | Teflon-Cut Pasta Extruder |

|---|---|---|

| Material | Bronze die | Teflon-coated die |

| Surface Texture | Rough, porous surface | Smooth, non-stick surface |

| Pasta Texture | Rough, better sauce adherence | Smoother, less sauce retention |

| Extrusion Speed | Slower, due to stickiness | Faster, smooth dough flow |

| Durability | Prone to wear and corrosion | High durability, resistant to corrosion |

| Cleaning | Challenging, dough sticks | Easy, non-stick surface |

| Cost | Lower initial cost | Higher initial cost |

| Common Use | Traditional pasta, artisanal production | Industrial pasta production |

Introduction to Pasta Extrusion Methods

Bronze-cut pasta extrusion creates rougher surfaces by pressing dough through bronze dies, enhancing sauce adherence and texture. Teflon-cut extrusion produces smoother pasta with non-stick surfaces, resulting in a glossier appearance but less sauce absorption. Selecting bronze-cut or Teflon-cut methods significantly impacts the pasta's mouthfeel, cooking performance, and culinary pairing.

What is Bronze-Cut Pasta?

Bronze-cut pasta is produced by extruding dough through bronze dies, creating a rough and porous surface that enhances sauce adhesion and texture. This traditional manufacturing method contrasts with Teflon-cut pasta, which uses smooth non-stick dies resulting in a slicker finish. The bronze-cut technique is prized for its ability to hold onto sauces better, offering a more authentic and flavorful pasta experience.

What is Teflon-Cut Pasta?

Teflon-cut pasta refers to pasta shaped using pasta dies coated with Teflon, resulting in a smooth surface texture that reduces sauce adherence. This extrusion method is faster and less abrasive on pasta dough compared to bronze-cut dies, producing pasta with a glossy finish and firmer bite when cooked. Teflon-cut pasta is commonly found in mass-produced varieties due to its efficiency and consistent shape quality.

Texture Differences: Bronze vs Teflon-Cut Pasta

Bronze-cut pasta features a rough, porous surface that better holds sauces, creating a more authentic texture favored in traditional Italian cuisine. Teflon-cut pasta has a smoother finish, resulting in a softer bite and less sauce adherence. The choice between bronze and Teflon extrusion directly influences the pasta's mouthfeel and sauce compatibility.

Flavor Impact of Extrusion Methods

Bronze-cut pasta surfaces create a rough texture that holds sauces better, enhancing flavor absorption and delivering a more authentic, rustic taste experience compared to smoother Teflon-cut pasta. The slightly porous nature of bronze-cut pasta allows for superior sauce clinging, intensifying each bite's flavor profile. Conversely, Teflon-cut pasta produces a sleek, less textured finish that can result in a milder flavor sensation due to reduced sauce adhesion.

Sauce Adherence: Which Extrusion is Better?

Bronze-cut pasta features a rougher surface texture that enhances sauce adherence, making it ideal for thick or chunky sauces. Teflon-cut pasta, with its smooth finish, tends to repel sauce, resulting in less flavor clinging. For recipes where sauce retention is critical, bronze-cut extrusion provides superior performance and a more authentic Italian dining experience.

Visual Appearance in Bronze and Teflon-Cut Pasta

Bronze-cut pasta features a rougher, porous surface that enhances sauce absorption and gives a rustic, artisanal appearance with slightly irregular edges. Teflon-cut pasta produces a smooth, glossy finish with uniform shapes, resulting in a more polished and refined look. The distinct textures influence not only the visual appeal but also the overall dining experience through sauce adherence.

Nutritional Considerations: Does Extrusion Matter?

Bronze-cut pasta features rougher, porous surfaces that enhance sauce adhesion and may improve digestibility by slowing starch gelatinization, while Teflon-cut pasta offers smoother textures with less surface area exposure. Nutritionally, extrusion methods minimally affect macronutrient content but can influence glycemic response due to differences in starch structure and protein interactions during processing. Selection between bronze-cut and Teflon-cut pasta should consider these subtle impacts on digestion and blood sugar regulation rather than substantial nutrient variations.

Cost and Availability of Bronze-Cut vs Teflon-Cut Pasta

Bronze-cut pasta is typically more expensive due to the higher production costs associated with bronze dies, which are less durable and require frequent replacement compared to Teflon-cut dies. Teflon-cut pasta dies are more widely available and cost-effective for mass production, enabling manufacturers to produce pasta at a lower price point. Despite the higher cost, bronze-cut pasta is often sought after for its superior texture and ability to hold sauces better, justifying the premium in gourmet markets.

Choosing the Right Pasta for Your Recipe

Bronze-cut pasta features a rougher texture that better holds sauces, making it ideal for hearty, thick, or chunky recipes like ragu or pesto. Teflon-cut pasta offers a smoother surface, which works well with light, delicate sauces or broths, enhancing subtle flavors without overpowering the dish. Selecting the right pasta extrusion method depends on the sauce's consistency and the desired texture, ensuring optimal flavor absorption and mouthfeel.

Bronze-cut vs Teflon-cut for pasta extruding Infographic

cookingdif.com

cookingdif.com