Bronze-cut pasta features a rougher texture due to the traditional bronze dies used in extrusion, which allows sauces to cling better, enhancing flavor absorption. Teflon-cut pasta, produced with non-stick dies, has a smoother surface that cooks faster but may not hold sauces as effectively. Choosing between bronze-cut and Teflon-cut pasta impacts the overall taste experience and sauce adherence.

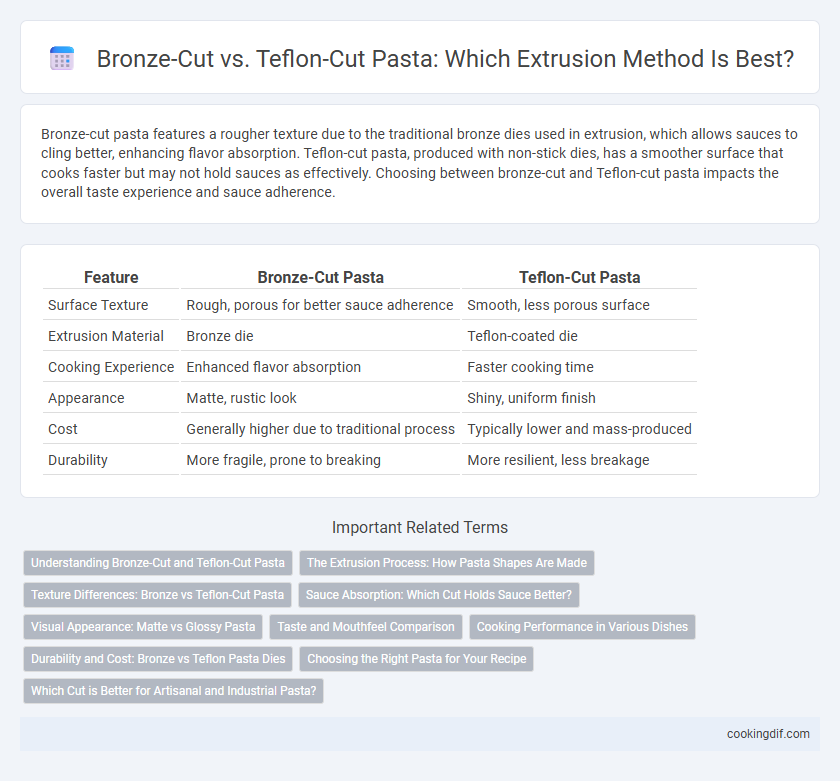

Table of Comparison

| Feature | Bronze-Cut Pasta | Teflon-Cut Pasta |

|---|---|---|

| Surface Texture | Rough, porous for better sauce adherence | Smooth, less porous surface |

| Extrusion Material | Bronze die | Teflon-coated die |

| Cooking Experience | Enhanced flavor absorption | Faster cooking time |

| Appearance | Matte, rustic look | Shiny, uniform finish |

| Cost | Generally higher due to traditional process | Typically lower and mass-produced |

| Durability | More fragile, prone to breaking | More resilient, less breakage |

Understanding Bronze-Cut and Teflon-Cut Pasta

Bronze-cut pasta is extruded through rough bronze dies, creating a porous surface that holds sauce better and enhances texture, making it ideal for traditional Italian dishes. Teflon-cut pasta uses smooth, non-stick Teflon dies, resulting in a sleeker, less porous surface that cooks more evenly and has a milder texture. Understanding these differences helps in selecting pasta types that suit specific recipes and desired mouthfeel.

The Extrusion Process: How Pasta Shapes Are Made

Bronze-cut pasta achieves a rough texture by using bronze dies during extrusion, which helps sauce cling better, enhancing flavor absorption. Teflon-cut pasta, made with non-stick Teflon dies, produces a smoother surface, resulting in a silkier mouthfeel but less sauce adherence. The extrusion process involves forcing dough through these shaped dies, where the choice between bronze or Teflon impacts the pasta's texture and its interaction with sauces.

Texture Differences: Bronze vs Teflon-Cut Pasta

Bronze-cut pasta features a rough, porous texture that allows sauces to cling more effectively, enhancing flavor absorption. Teflon-cut pasta has a smooth, glossy surface resulting in a firmer bite but less sauce adherence. The choice between bronze and Teflon extrusion significantly impacts the pasta's mouthfeel and how it interacts with various sauces.

Sauce Absorption: Which Cut Holds Sauce Better?

Bronze-cut pasta features a rougher, porous texture that enhances sauce adhesion and absorbs flavor more effectively compared to the smooth, non-stick surface of Teflon-cut pasta. This increased surface roughness creates tiny grooves that trap thicker sauces like marinara and ragu, providing a more flavorful bite. Consequently, bronze-cut pasta is preferred for recipes requiring robust sauce retention and improved mouthfeel.

Visual Appearance: Matte vs Glossy Pasta

Bronze-cut pasta exhibits a rough, matte surface due to the porous texture of the bronze dies, enhancing sauce adhesion and providing an artisanal, rustic appearance. Teflon-cut pasta, produced with smooth, non-stick dies, results in a glossy, polished finish that repels sauce more easily, offering a cleaner, uniform look. The choice between bronze-cut and Teflon-cut extrusion significantly impacts the pasta's texture and visual appeal, influencing both culinary presentation and flavor integration.

Taste and Mouthfeel Comparison

Bronze-cut pasta features a rougher texture that enhances sauce adherence, delivering a more authentic, al dente bite and richer mouthfeel favored in traditional Italian cuisine. Teflon-cut pasta, with its smoother surface, offers a softer, silkier texture that cooks faster but may result in a less robust taste experience. The choice between bronze and Teflon extrusion directly influences the pasta's ability to absorb flavors and its tactile sensation during consumption.

Cooking Performance in Various Dishes

Bronze-cut pasta retains a rougher texture that enhances sauce adherence, resulting in a more flavorful eating experience across diverse dishes like ragu or pesto. Teflon-cut pasta offers a smoother surface, cooking faster but often causing sauces to slide off, which may be less desirable for rich, thick sauces. Selecting bronze-cut pasta improves cooking performance by maximizing sauce absorption and texture retention in complex recipes.

Durability and Cost: Bronze vs Teflon Pasta Dies

Bronze-cut pasta dies offer superior durability, maintaining their rough texture longer for authentic sauce adherence, but they come with higher initial costs and require more frequent maintenance due to corrosion risk. Teflon-cut dies are more cost-effective and resistant to wear and corrosion, resulting in lower long-term maintenance expenses, but they produce smoother pasta surfaces that may affect sauce retention. Producers must balance the premium durability and texture benefits of bronze dies against the economical and maintenance advantages of Teflon dies when selecting extrusion methods.

Choosing the Right Pasta for Your Recipe

Bronze-cut pasta features a rough, porous texture that clings better to sauces, making it ideal for hearty, robust dishes. Teflon-cut pasta has a smoother surface, resulting in a softer bite preferred in lighter recipes and delicate sauces. Selecting between bronze-cut and Teflon-cut pasta depends on the desired sauce adherence and texture to complement the specific flavor profile of your recipe.

Which Cut is Better for Artisanal and Industrial Pasta?

Bronze-cut extrusion produces rougher pasta surfaces that retain sauces better, making it ideal for artisanal pasta focused on texture and flavor enhancement. Teflon-cut extrusion results in smoother pasta with faster production rates, preferred in industrial pasta manufacturing for consistency and efficiency. For artisanal quality, bronze-cut pasta is superior, while Teflon-cut suits large-scale industrial pasta production.

bronze-cut vs Teflon-cut for extrusion Infographic

cookingdif.com

cookingdif.com