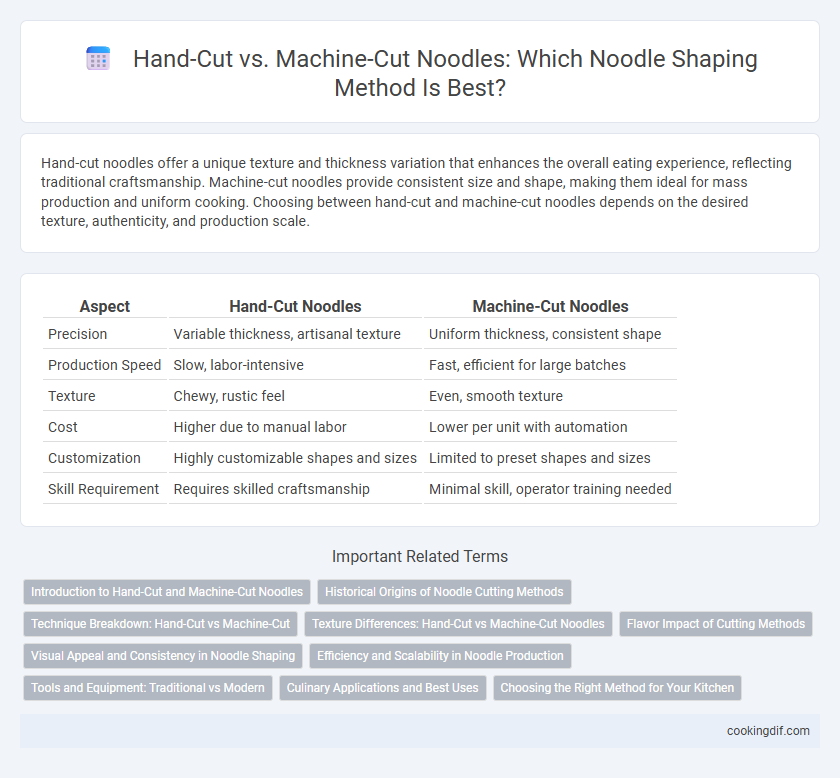

Hand-cut noodles offer a unique texture and thickness variation that enhances the overall eating experience, reflecting traditional craftsmanship. Machine-cut noodles provide consistent size and shape, making them ideal for mass production and uniform cooking. Choosing between hand-cut and machine-cut noodles depends on the desired texture, authenticity, and production scale.

Table of Comparison

| Aspect | Hand-Cut Noodles | Machine-Cut Noodles |

|---|---|---|

| Precision | Variable thickness, artisanal texture | Uniform thickness, consistent shape |

| Production Speed | Slow, labor-intensive | Fast, efficient for large batches |

| Texture | Chewy, rustic feel | Even, smooth texture |

| Cost | Higher due to manual labor | Lower per unit with automation |

| Customization | Highly customizable shapes and sizes | Limited to preset shapes and sizes |

| Skill Requirement | Requires skilled craftsmanship | Minimal skill, operator training needed |

Introduction to Hand-Cut and Machine-Cut Noodles

Hand-cut noodles are crafted using traditional techniques where dough is manually sliced into uneven, rustic strips that enhance texture and absorb sauces effectively. Machine-cut noodles offer uniform thickness and consistency, streamlining production for large-scale manufacturing and ensuring reproducible quality. Both methods impact noodle shape and cooking performance, influencing dining experience and regional culinary preferences.

Historical Origins of Noodle Cutting Methods

Hand-cut noodle shaping traces back to ancient China, where skilled artisans used knives to create noodles with varied textures and thicknesses. Machine-cut noodles emerged during the Industrial Revolution, enabling mass production and consistent shapes, revolutionizing noodle manufacturing worldwide. The transition from hand-cut to machine-cut reflects technological advancements and cultural shifts in noodle consumption practices.

Technique Breakdown: Hand-Cut vs Machine-Cut

Hand-cut noodles feature uneven edges and varied thickness, enhancing sauce absorption and creating a textured mouthfeel, prized in artisanal and traditional cuisines. Machine-cut noodles deliver uniform thickness and precise shapes, enabling consistent cooking times and streamlined mass production in commercial kitchens. Each technique influences noodle texture and flavor differently, with hand-cut favoring rustic authenticity and machine-cut emphasizing efficiency and consistency.

Texture Differences: Hand-Cut vs Machine-Cut Noodles

Hand-cut noodles possess a unique texture characterized by irregular thickness and a rustic chewiness, resulting from the manual slicing process that preserves the dough's natural variations. Machine-cut noodles offer uniform thickness and consistent texture, creating a smooth and predictable bite ideal for industrial-scale production. The choice between hand-cut and machine-cut impacts mouthfeel significantly, influencing the overall eating experience based on texture preferences.

Flavor Impact of Cutting Methods

Hand-cut noodles often retain more texture and variations in thickness, which enhances sauce absorption and creates a richer, more flavorful bite. Machine-cut noodles provide uniformity and consistency but may lack the subtle texture differences that influence mouthfeel and the overall taste experience. The physical interaction during hand-cutting can also slightly alter the noodle's surface, contributing to a nuanced flavor profile compared to the smooth, even edges of machine-cut noodles.

Visual Appeal and Consistency in Noodle Shaping

Hand-cut noodles offer a rustic, artisanal appearance with slight variations in thickness and shape, enhancing visual appeal through unique textures. Machine-cut noodles provide uniformity and precision, ensuring consistent size and shape for even cooking and professional presentation. Consistent noodle shaping by machines supports mass production efficiency while hand-cut methods emphasize traditional craftsmanship and aesthetic diversity.

Efficiency and Scalability in Noodle Production

Hand-cut noodles offer artisanal texture and customization but are limited by slower production speeds and labor intensity, making them less efficient for large-scale operations. Machine-cut noodles significantly enhance production efficiency and scalability by automating shaping processes and enabling consistent noodle size and quality at high volumes. Industrial noodle manufacturers primarily rely on machine-cut methods to meet increasing market demand while maintaining cost-effectiveness and production consistency.

Tools and Equipment: Traditional vs Modern

Hand-cut noodles rely on simple, traditional tools such as sharp knives and wooden cutting boards to create uneven, artisanal textures prized in regional cuisines. In contrast, machine-cut noodles use modern equipment like rotary cutters and automated dough sheeters, enabling precise thickness and uniform shapes that enhance large-scale production efficiency. The choice between hand-cut and machine-cut methods significantly influences noodle texture, cooking time, and overall culinary experience.

Culinary Applications and Best Uses

Hand-cut noodles offer irregular thickness and texture, enhancing sauce absorption and ideal for rustic dishes like beef noodle soup or stir-fries. Machine-cut noodles provide uniform thickness and consistent cooking times, making them suitable for high-volume restaurants and precise recipes such as ramen or chilled noodle salads. Choosing between hand-cut and machine-cut depends on desired texture, dish complexity, and production scale in culinary applications.

Choosing the Right Method for Your Kitchen

Hand-cut noodles offer artisanal texture and irregular shapes that enhance sauce adherence, making them ideal for traditional dishes requiring a rustic feel. Machine-cut noodles provide uniformity, efficiency, and scalability, perfect for high-volume kitchens prioritizing consistency. Selecting between hand-cut and machine-cut depends on your kitchen's volume demands, desired noodle texture, and preparation style.

Hand-cut vs machine-cut for noodle shaping Infographic

cookingdif.com

cookingdif.com