Hand-layered lasagna offers a personalized touch, with each layer carefully arranged to balance flavors and textures, resulting in a rich, artisanal dish. Assembly line preparation enhances efficiency and consistency, ideal for large-scale production where uniformity and speed are priorities. Choosing between the two methods depends on whether quality craftsmanship or volume output is the primary goal.

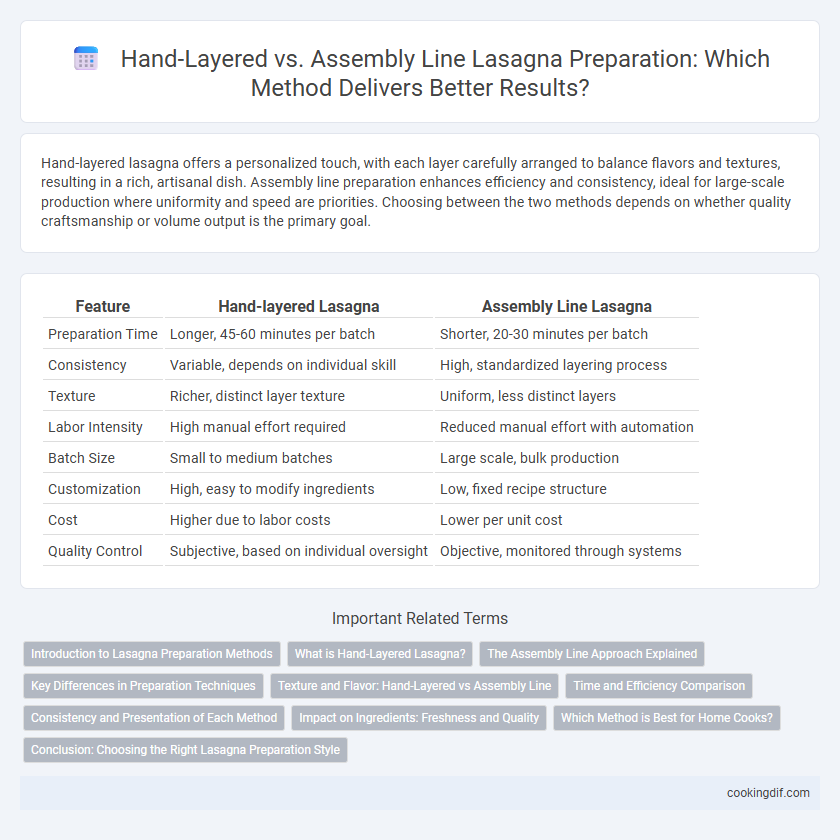

Table of Comparison

| Feature | Hand-layered Lasagna | Assembly Line Lasagna |

|---|---|---|

| Preparation Time | Longer, 45-60 minutes per batch | Shorter, 20-30 minutes per batch |

| Consistency | Variable, depends on individual skill | High, standardized layering process |

| Texture | Richer, distinct layer texture | Uniform, less distinct layers |

| Labor Intensity | High manual effort required | Reduced manual effort with automation |

| Batch Size | Small to medium batches | Large scale, bulk production |

| Customization | High, easy to modify ingredients | Low, fixed recipe structure |

| Cost | Higher due to labor costs | Lower per unit cost |

| Quality Control | Subjective, based on individual oversight | Objective, monitored through systems |

Introduction to Lasagna Preparation Methods

Hand-layered lasagna involves meticulously stacking fresh pasta sheets, rich meat sauce, creamy bechamel, and cheese, offering a traditional, textured experience. Assembly line preparation streamlines the process by dividing tasks such as sauce spreading, layering, and topping among multiple workers, enhancing efficiency in commercial kitchens. Both methods impact the final texture and flavor, with hand-layering emphasizing artisanal quality and assembly lines prioritizing volume and speed.

What is Hand-Layered Lasagna?

Hand-layered lasagna involves carefully placing each pasta sheet, sauce, cheese, and filling in distinct, deliberate layers, ensuring balanced texture and flavor in every bite. This traditional method enhances the depth of flavor by allowing ingredients to meld naturally during baking, resulting in a homemade taste and artisanal quality. Unlike assembly line production, hand-layered preparation emphasizes craftsmanship and customization, often yielding a richer, more satisfying lasagna experience.

The Assembly Line Approach Explained

The assembly line approach to lasagna preparation streamlines the process by dividing tasks into specific stations, allowing for consistent layering of ingredients such as pasta sheets, meat sauce, bechamel, and cheese. This method enhances efficiency in commercial kitchens, reducing preparation time and ensuring uniform quality across multiple portions. By systematizing each step, assembly line production maintains high output while minimizing errors commonly associated with hand-layered techniques.

Key Differences in Preparation Techniques

Hand-layered lasagna involves placing each ingredient individually, allowing for precise control over texture and ingredient distribution, resulting in a more artisanal, visually appealing dish. Assembly line preparation uses a streamlined process where components are stacked rapidly in large quantities, optimizing efficiency and consistency for commercial production. The key difference lies in customization and detail versus speed and volume, affecting the finished lasagna's flavor complexity and presentation.

Texture and Flavor: Hand-Layered vs Assembly Line

Hand-layered lasagna offers a superior texture and richer flavor due to the careful placement of varied ingredients, allowing sauces and cheeses to meld naturally. Assembly line preparation can lead to uniform but less nuanced layers, often resulting in a flatter texture and muted taste profile. Artisanal hand layering maximizes ingredient interaction, enhancing overall sensory experience in every bite.

Time and Efficiency Comparison

Hand-layered lasagna preparation offers a traditional approach with meticulous attention to ingredient placement, often resulting in longer preparation times averaging 30 to 45 minutes per pan. Assembly line methods streamline the process by dividing tasks into specialized steps, significantly reducing preparation time to approximately 10 to 15 minutes per pan while enhancing consistency and throughput. Efficiency in assembly line production supports large-scale cooking environments by minimizing labor intensity and optimizing ingredient usage, making it ideal for commercial kitchens and catering services.

Consistency and Presentation of Each Method

Hand-layered lasagna offers unique texture variations and a rustic appearance, but consistency can vary between portions due to manual spreading. Assembly line preparation ensures uniform layer thickness and precise ingredient distribution, resulting in consistent flavor and a polished, professional presentation. Restaurants prioritizing efficiency and repeatability favor assembly lines, while artisanal kitchens may prefer hand-layering to highlight homemade craftsmanship.

Impact on Ingredients: Freshness and Quality

Hand-layered lasagna allows for precise control over ingredient quality and freshness, ensuring each layer maintains optimal texture and flavor. Assembly line preparation may speed up production but can compromise the freshness of ingredients due to batch processing and extended holding times. Prioritizing hand-layering enhances the overall taste experience by preserving ingredient integrity and minimizing degradation.

Which Method is Best for Home Cooks?

Hand-layered lasagna offers home cooks greater control over ingredient distribution, allowing for personalized textures and flavors in each slice. Assembly line preparation speeds up the process, making it ideal for larger batches but may sacrifice the artisanal quality that hand-layering provides. For home cooks prioritizing freshness and customization, hand-layered methods are often the best choice.

Conclusion: Choosing the Right Lasagna Preparation Style

Hand-layered lasagna offers a personalized texture and flavor profile, emphasizing artisanal craftsmanship and ingredient control. Assembly line preparation maximizes efficiency and consistency, ideal for large-scale production while maintaining quality standards. Selecting the right preparation style depends on balancing the need for customization with volume demands and production capacity.

Hand-layered vs Assembly Line for preparation Infographic

cookingdif.com

cookingdif.com