Steam injection in an oven creates a moist environment that enhances oven spring by keeping the bread crust pliable during the initial baking phase, allowing maximum expansion. Using a Dutch oven traps steam released from the dough itself, providing a similar effect but with more consistent localized humidity and heat retention. Both methods improve crust development and rise, but steam injection offers precise control, while the Dutch oven is favored for artisanal, home baking convenience.

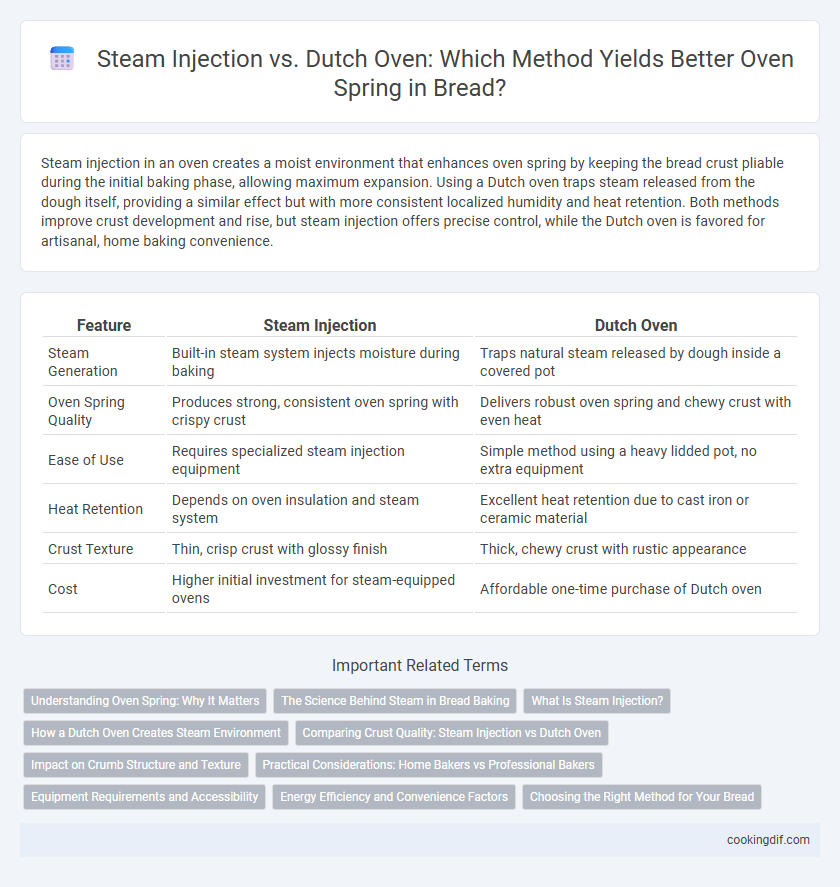

Table of Comparison

| Feature | Steam Injection | Dutch Oven |

|---|---|---|

| Steam Generation | Built-in steam system injects moisture during baking | Traps natural steam released by dough inside a covered pot |

| Oven Spring Quality | Produces strong, consistent oven spring with crispy crust | Delivers robust oven spring and chewy crust with even heat |

| Ease of Use | Requires specialized steam injection equipment | Simple method using a heavy lidded pot, no extra equipment |

| Heat Retention | Depends on oven insulation and steam system | Excellent heat retention due to cast iron or ceramic material |

| Crust Texture | Thin, crisp crust with glossy finish | Thick, chewy crust with rustic appearance |

| Cost | Higher initial investment for steam-equipped ovens | Affordable one-time purchase of Dutch oven |

Understanding Oven Spring: Why It Matters

Oven spring refers to the rapid rise of bread dough during the first few minutes of baking, crucial for achieving a light, airy crumb and an appealing crust. Steam injection creates a moist environment that delays crust formation, allowing the dough to expand more fully and enhances the oven spring. In contrast, a Dutch oven traps steam released from the dough itself, providing controlled humidity that supports oven spring while developing a well-structured crust.

The Science Behind Steam in Bread Baking

Steam injection in professional ovens creates a humid environment that delays crust formation, allowing maximum dough expansion and superior oven spring by keeping the outer gluten layer moist and extensible. Dutch ovens trap moisture released by the dough itself, generating steam in a closed environment that promotes similar crust elasticity and volume increase, though with typically less precise steam control than commercial steam injection. The presence of steam influences starch gelatinization and Maillard reactions, resulting in a glossy, thin crust while enhancing gas retention during the critical first minutes of baking.

What Is Steam Injection?

Steam injection is a baking technique where water vapor is introduced into the oven during the initial baking phase to enhance crust development and improve oven spring in bread. This method creates a humid environment that delays crust formation, allowing the dough to expand fully, resulting in a lighter, airier loaf. Compared to Dutch oven baking, which traps steam naturally within a closed container, steam injection provides more controlled and consistent moisture levels throughout the baking process.

How a Dutch Oven Creates Steam Environment

A Dutch oven creates a steam environment by trapping moisture released from the dough during baking, which condenses on the lid and continuously drenches the bread. This sealed, humid atmosphere prevents the crust from hardening too quickly, allowing the dough to expand fully and achieve optimal oven spring. The intense, natural steam inside a Dutch oven replicates professional steam injection ovens, enhancing crust texture and volume without the need for external moisture sources.

Comparing Crust Quality: Steam Injection vs Dutch Oven

Steam injection creates a crisp, shiny crust by maintaining high humidity during the initial baking phase, resulting in better oven spring and a thin, crackly surface. A Dutch oven traps natural steam from the dough, producing a thick, chewy crust with a slightly matte finish and a rustic appearance. Comparing crust quality, steam injection offers uniform crust development and enhanced coloration, while the Dutch oven provides a more artisanal texture with deeper caramelization.

Impact on Crumb Structure and Texture

Steam injection in ovens enhances oven spring by keeping the dough surface moist, allowing for better expansion and a crisp crust, which results in an open, airy crumb with a tender texture. Dutch ovens create a micro-steam environment by trapping moisture released from the dough itself, producing a similar oven spring but often yielding a denser crumb with a chewier texture. The controlled steam environment of a Dutch oven tends to produce a more uniform crust and softer interior compared to the intense, external steam injection that promotes a lighter, more open crumb structure.

Practical Considerations: Home Bakers vs Professional Bakers

Steam injection ovens offer precise humidity control, ideal for professional bakers who require consistent oven spring and crust development in high-volume baking. Home bakers often prefer Dutch ovens due to their affordability, ease of use, and effective steam retention from enclosed baking, which enhances oven spring without specialized equipment. Dutch ovens provide a practical solution for artisanal bread baking at home, while steam injection remains the preferred method in commercial bakeries for optimal performance and scalability.

Equipment Requirements and Accessibility

Steam injection ovens require specialized equipment to introduce moisture during baking, often found in commercial or professional setups, which can limit accessibility for home bakers. Dutch ovens provide a more accessible alternative by trapping steam naturally, requiring only a heavy, lidded pot that is widely available and easy to use in conventional home ovens. This makes Dutch ovens a practical choice for achieving significant oven spring without the need for advanced steam injection systems.

Energy Efficiency and Convenience Factors

Steam injection ovens enhance oven spring by creating a moist environment that improves crust formation and bread volume while using controlled heat release for energy efficiency. Dutch ovens trap steam naturally within a sealed, preheated pot, allowing for excellent oven spring with minimal energy loss due to their insulated design. Convenience favors Dutch ovens for home bakers because they require no specialized equipment, whereas steam injection ovens demand specific oven features and maintenance.

Choosing the Right Method for Your Bread

Steam injection creates a humid environment that promotes optimal oven spring by keeping the crust soft longer, allowing the bread to expand fully during baking. Dutch ovens trap moisture released from the dough, providing a natural steam effect ideal for home bakers seeking artisan-style crust and texture. Selecting between steam injection and a Dutch oven depends on the baking setup and desired crust characteristics, with steam injection suited for professional ovens and Dutch ovens perfect for home kitchens.

Steam injection vs Dutch oven for oven spring Infographic

cookingdif.com

cookingdif.com