Bench rest and bulk fermentation are two critical stages in bread making that influence dough development and flavor. Bulk fermentation allows the dough to rise as a whole, promoting yeast activity and gluten formation, while bench rest occurs after dividing and shaping, giving the dough time to relax for easier handling. Properly timing these stages ensures optimal texture, crumb structure, and overall bread quality.

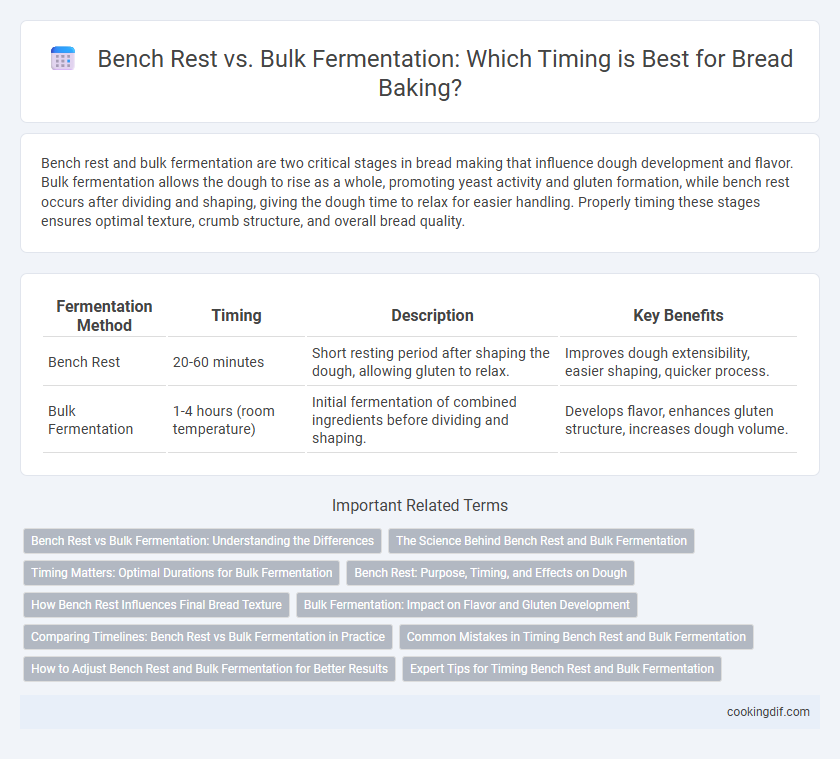

Table of Comparison

| Fermentation Method | Timing | Description | Key Benefits |

|---|---|---|---|

| Bench Rest | 20-60 minutes | Short resting period after shaping the dough, allowing gluten to relax. | Improves dough extensibility, easier shaping, quicker process. |

| Bulk Fermentation | 1-4 hours (room temperature) | Initial fermentation of combined ingredients before dividing and shaping. | Develops flavor, enhances gluten structure, increases dough volume. |

Bench Rest vs Bulk Fermentation: Understanding the Differences

Bench rest involves a short resting period after dough mixing, typically lasting 20 to 30 minutes, allowing gluten strands to relax for easier shaping. Bulk fermentation, on the other hand, is a longer fermentation phase that can last from 1 to 4 hours or more, during which yeast activity produces gas and flavor development throughout the entire dough mass. Understanding the timing differences between bench rest and bulk fermentation is crucial for optimizing bread texture, crumb structure, and overall flavor complexity.

The Science Behind Bench Rest and Bulk Fermentation

Bench rest allows gluten to relax and yeast activity to resume briefly after shaping, improving dough extensibility for better oven spring. Bulk fermentation involves fermenting the entire dough mass before shaping, during which yeast produces carbon dioxide, organic acids, and enzymes that develop flavor and dough structure. Understanding the biochemical processes during these stages helps bakers optimize timing to balance gluten development, gas retention, and flavor complexity in bread.

Timing Matters: Optimal Durations for Bulk Fermentation

Bulk fermentation typically lasts between 3 to 5 hours at room temperature, allowing yeast to develop complex flavors and improve dough structure, whereas bench rest is a shorter period, around 20 to 30 minutes, aimed at relaxing gluten before shaping. Proper timing during bulk fermentation is crucial for optimal dough rise and flavor enhancement, as under-fermentation leads to dense bread and over-fermentation causes collapse or sourness. Monitoring dough elasticity and volume increase during bulk fermentation ensures balanced fermentation, resulting in better crumb texture and taste.

Bench Rest: Purpose, Timing, and Effects on Dough

Bench rest, also known as the intermediate proofing phase, allows the dough to relax after shaping, typically lasting 20 to 40 minutes. This process enhances gluten development and improves dough extensibility, resulting in better oven spring and crumb texture. Unlike bulk fermentation which focuses on yeast activity and fermentation, bench rest primarily targets dough handling properties and shaping quality.

How Bench Rest Influences Final Bread Texture

Bench rest plays a crucial role in developing dough gluten structure and hydration, directly impacting the final bread texture by promoting better gas retention and a tender crumb. During this stage, dough temperature and time ensure optimal yeast activity, resulting in a more even crumb with enhanced chewiness and elasticity. Properly timed bench rest prevents over-fermentation, maintaining dough strength and producing bread with improved volume and a desirable crust.

Bulk Fermentation: Impact on Flavor and Gluten Development

Bulk fermentation plays a crucial role in flavor development and gluten structure by allowing yeast activity to create organic acids and enzymes that enhance taste complexity. During bulk fermentation, gluten strands strengthen and align, improving dough elasticity and crumb texture in the final bread. Proper timing of bulk fermentation, typically ranging from 1 to 4 hours depending on temperature and hydration, directly influences the bread's aroma and mouthfeel.

Comparing Timelines: Bench Rest vs Bulk Fermentation in Practice

Bench rest typically lasts 15 to 30 minutes and allows the dough to relax and gluten to develop between shaping and final proofing, while bulk fermentation extends from 1 to 4 hours depending on temperature and yeast activity, promoting flavor development and gas retention. Bulk fermentation requires constant monitoring to avoid over-fermentation, whereas bench rest provides a controlled pause for dough handling. Efficient bread-making demands balancing these timelines to optimize texture, crumb structure, and flavor complexity.

Common Mistakes in Timing Bench Rest and Bulk Fermentation

Timing errors in bench rest and bulk fermentation often result in underproofed or overproofed dough, impairing texture and flavor development. Common mistakes include rushing bulk fermentation, which prevents proper gluten formation, and extending bench rest too long, causing dough collapse and loss of oven spring. Accurate timing and monitoring of dough elasticity and volume are crucial to optimize yeast activity and achieve consistent bread quality.

How to Adjust Bench Rest and Bulk Fermentation for Better Results

Adjust bench rest by monitoring dough temperature, typically aiming for 20-22degC to control yeast activity and improve gluten development. Bulk fermentation timing depends on ambient temperature and dough hydration, often lasting 1-3 hours for optimal flavor and crumb structure. Adjust by conducting shorter bench rests after a longer bulk fermentation to enhance dough extensibility and final loaf volume.

Expert Tips for Timing Bench Rest and Bulk Fermentation

Bench rest typically lasts 20 to 30 minutes, allowing the dough to relax and become easier to shape, while bulk fermentation ranges from 1 to 4 hours depending on the yeast activity and ambient temperature. Expert tips emphasize monitoring dough elasticity and gas retention during bulk fermentation to prevent over-proofing and maintain crumb structure. Timing adjustments based on flour type, hydration, and room conditions optimize fermentation outcomes and enhance bread texture and flavor.

Bench rest vs bulk fermentation for timing Infographic

cookingdif.com

cookingdif.com