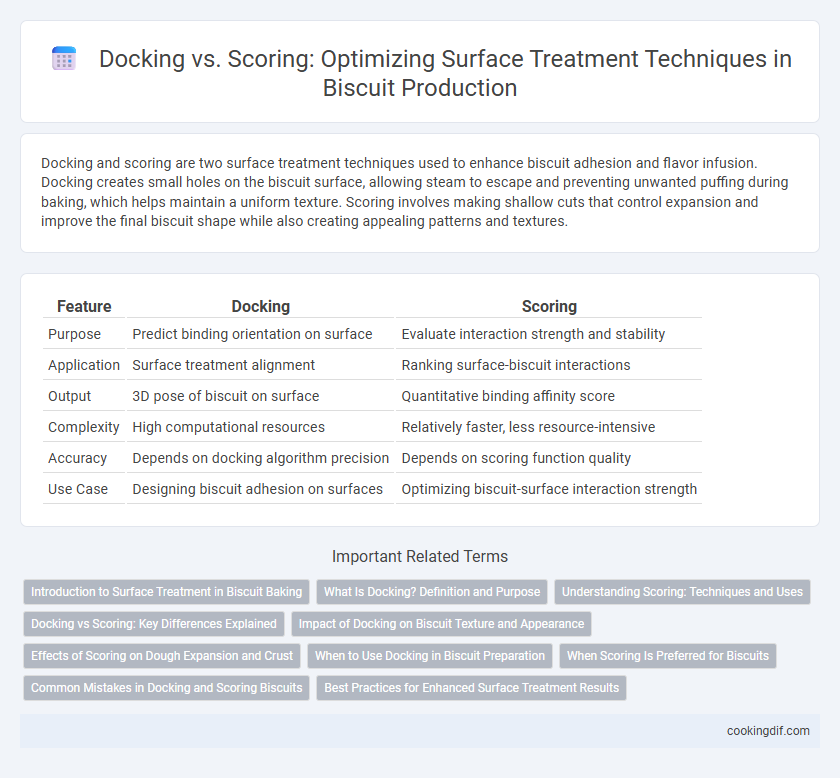

Docking and scoring are two surface treatment techniques used to enhance biscuit adhesion and flavor infusion. Docking creates small holes on the biscuit surface, allowing steam to escape and preventing unwanted puffing during baking, which helps maintain a uniform texture. Scoring involves making shallow cuts that control expansion and improve the final biscuit shape while also creating appealing patterns and textures.

Table of Comparison

| Feature | Docking | Scoring |

|---|---|---|

| Purpose | Predict binding orientation on surface | Evaluate interaction strength and stability |

| Application | Surface treatment alignment | Ranking surface-biscuit interactions |

| Output | 3D pose of biscuit on surface | Quantitative binding affinity score |

| Complexity | High computational resources | Relatively faster, less resource-intensive |

| Accuracy | Depends on docking algorithm precision | Depends on scoring function quality |

| Use Case | Designing biscuit adhesion on surfaces | Optimizing biscuit-surface interaction strength |

Introduction to Surface Treatment in Biscuit Baking

Surface treatment in biscuit baking plays a critical role in enhancing texture and appearance, with docking and scoring being two fundamental techniques. Docking involves piercing the dough to release steam and prevent excessive rising, ensuring a uniform and crisp finished product. Scoring, on the other hand, creates controlled fissures on the dough surface, contributing to aesthetic patterns and aiding in consistent baking by directing expansion.

What Is Docking? Definition and Purpose

Docking in surface treatment refers to the precise alignment and attachment of biscuit components to ensure optimal adhesion and structural integrity. Its primary purpose is to create a consistent and reliable surface interface, improving the bonding strength between biscuit layers or coatings. This technique enhances the overall durability and quality of the final biscuit product by minimizing defects and surface irregularities.

Understanding Scoring: Techniques and Uses

Scoring involves creating precise, controlled lines on biscuit surfaces to enhance adhesion and improve finish durability during surface treatment. Techniques include using specialized blades or rollers to produce consistent grooves that facilitate paint or coating bonding. This method is widely applied in both artisanal and industrial biscuit production to optimize surface texture and ensure even application of treatments.

Docking vs Scoring: Key Differences Explained

Docking involves joining two pieces of wood end-to-end using interlocking cuts to create a strong, precise bond, while scoring refers to making shallow cuts or grooves on the surface to improve adhesive grip or flexibility in surface treatment. Docking provides structural integrity and alignment vital for biscuit joints, whereas scoring primarily enhances surface texture for better glue adhesion. Understanding these differences ensures optimal biscuit joint performance and surface durability in woodworking projects.

Impact of Docking on Biscuit Texture and Appearance

Docking significantly influences biscuit texture by promoting even heat distribution, which prevents excessive puffing and ensures a consistent crumb structure. Proper docking patterns reduce surface blistering and cracking, resulting in a smoother, more uniform appearance. This technique enhances the overall sensory quality of biscuits, contributing to improved consumer appeal.

Effects of Scoring on Dough Expansion and Crust

Scoring on biscuit dough controls gas expansion during baking, allowing for uniform rise and preventing random cracking on the crust. This method influences the texture by directing steam release and enhancing crust crispness, which improves overall appearance and mouthfeel. Proper scoring depth and pattern optimize dough expansion and crust formation, resulting in consistent biscuit quality.

When to Use Docking in Biscuit Preparation

Docking is essential in biscuit preparation when preventing excessive rising and ensuring even cooking, as it creates small perforations that allow steam to escape. This technique is particularly useful for thin or flaky biscuits where maintaining a uniform texture and preventing bubbling is critical. Use docking whenever surface tension could compromise the biscuit's structural integrity during baking.

When Scoring Is Preferred for Biscuits

Scoring is preferred for biscuits when precise portion control and clean break lines are essential, enhancing the consumer's convenience and presentation quality. This technique creates intentional, shallow indentations that facilitate easy snapping without crumbling, maintaining the biscuit's structural integrity and texture. Scoring is particularly beneficial for high-quality, delicate biscuits where controlled portions improve packaging efficiency and reduce product waste.

Common Mistakes in Docking and Scoring Biscuits

Common mistakes in docking and scoring biscuits include inaccurate alignment, which compromises the joint's strength and leads to gaps or misfits. Insufficient depth control during docking reduces the surface area for adhesive bonding, weakening the overall joint durability. Overlooking proper scoring techniques can cause uneven biscuit expansion, resulting in poor adhesion and structural instability.

Best Practices for Enhanced Surface Treatment Results

Docking and scoring are critical methods for surface treatment, with docking ensuring precise alignment and secure attachment while scoring promotes improved adhesion by creating microabrasions. Best practices prioritize using docking techniques for delicate surfaces to prevent damage and scoring on durable materials to enhance surface roughness for coating adherence. Optimizing parameters such as pressure, angle, and pattern during these processes leads to enhanced surface treatment results and prolonged material performance.

Docking vs Scoring for surface treatment Infographic

cookingdif.com

cookingdif.com