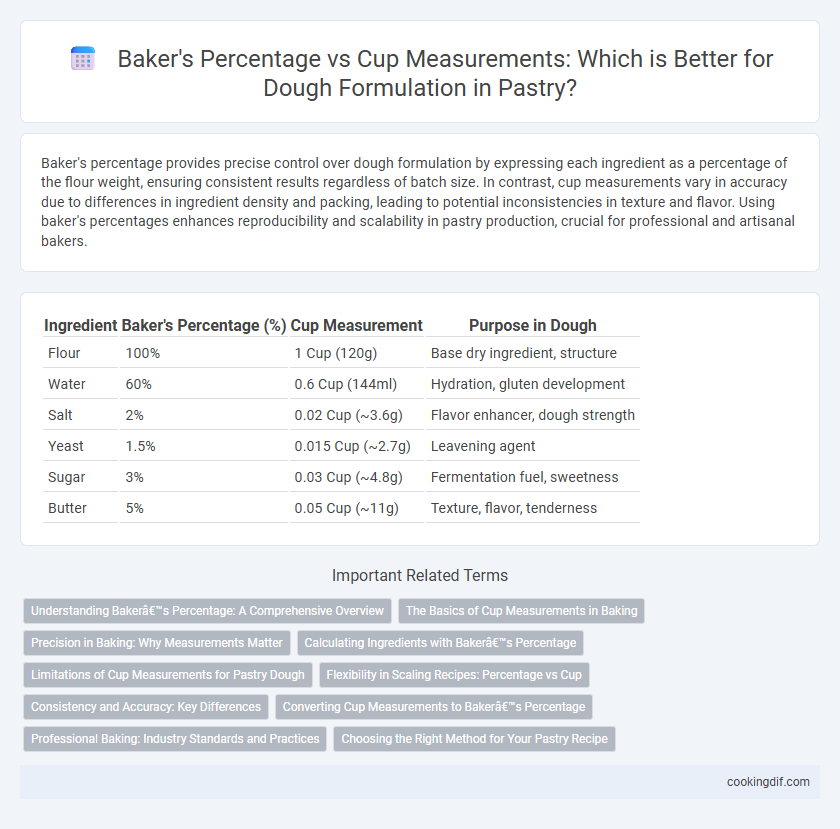

Baker's percentage provides precise control over dough formulation by expressing each ingredient as a percentage of the flour weight, ensuring consistent results regardless of batch size. In contrast, cup measurements vary in accuracy due to differences in ingredient density and packing, leading to potential inconsistencies in texture and flavor. Using baker's percentages enhances reproducibility and scalability in pastry production, crucial for professional and artisanal bakers.

Table of Comparison

| Ingredient | Baker's Percentage (%) | Cup Measurement | Purpose in Dough |

|---|---|---|---|

| Flour | 100% | 1 Cup (120g) | Base dry ingredient, structure |

| Water | 60% | 0.6 Cup (144ml) | Hydration, gluten development |

| Salt | 2% | 0.02 Cup (~3.6g) | Flavor enhancer, dough strength |

| Yeast | 1.5% | 0.015 Cup (~2.7g) | Leavening agent |

| Sugar | 3% | 0.03 Cup (~4.8g) | Fermentation fuel, sweetness |

| Butter | 5% | 0.05 Cup (~11g) | Texture, flavor, tenderness |

Understanding Baker’s Percentage: A Comprehensive Overview

Baker's percentage expresses ingredient quantities relative to the flour weight, enhancing precision in dough formulation compared to traditional cup measurements. Each ingredient's weight is calculated as a percentage of the total flour weight, allowing easy scaling and consistent results across different batch sizes. This method improves accuracy in pastry recipes by eliminating volume inconsistencies inherent in cup measurements, ensuring optimal texture and flavor development.

The Basics of Cup Measurements in Baking

Cup measurements in baking quantify ingredients by volume, essential for home bakers who rely on straightforward tools rather than scales. Unlike the precision of baker's percentage, cup measurements can vary due to ingredient density and packing methods, impacting dough consistency and final texture. Understanding these variations helps bakers adjust recipes effectively to achieve desired pastry quality.

Precision in Baking: Why Measurements Matter

Baker's Percentage provides precise control over dough formulation by expressing each ingredient as a percentage of the flour weight, ensuring consistent results across batches. Cup measurements lack this accuracy due to variations in ingredient density and packing, leading to inconsistent dough texture and rise. Precision in baking demands Baker's Percentage to optimize ingredient ratios and achieve predictable, high-quality pastries.

Calculating Ingredients with Baker’s Percentage

Baker's percentage calculates each ingredient as a percentage of the flour weight, providing precise and scalable dough formulations compared to inconsistent cup measurements. This method enhances consistency in pastry production by standardizing ingredient ratios, such as water at 60%, sugar at 5%, and yeast at 1.5%, relative to flour at 100%. Using baker's percentage allows bakers to easily adjust batch sizes while maintaining dough characteristics critical for texture and rise.

Limitations of Cup Measurements for Pastry Dough

Cup measurements lack precision in pastry dough formulation due to variability in ingredient density and compaction, leading to inconsistent dough hydration and texture. Baker's percentage provides a standardized framework by expressing ingredient ratios relative to flour weight, ensuring reproducible results across batches. Reliance on volume measurements can result in uneven pastry quality, emphasizing the necessity of weight-based methods for professional baking accuracy.

Flexibility in Scaling Recipes: Percentage vs Cup

Baker's percentage offers precise control by expressing ingredient ratios relative to flour weight, allowing seamless scalability from small batches to large production without altering dough consistency. Cup measurements, while convenient for home baking, lack exact proportional relationships, leading to inconsistencies when scaling recipes up or down. Utilizing percentages enhances recipe accuracy and repeatability crucial for professional pastry dough formulation.

Consistency and Accuracy: Key Differences

Baker's percentage provides precise consistency by expressing each ingredient as a ratio of flour weight, enabling accurate replication and scaling of dough formulations. Cup measurements vary based on ingredient density and packing, often causing fluctuations in dough texture and performance. Using baker's percentage ensures dough accuracy and predictability, essential for professional and large-scale baking operations.

Converting Cup Measurements to Baker’s Percentage

Converting cup measurements to baker's percentage involves expressing each ingredient's weight as a percentage of the flour weight, which is standardized at 100%. Accurate conversion requires weighing ingredients in grams rather than relying on volume, as cup measurements vary by density and packing. Using baker's percentage ensures precise scaling and consistency in dough formulation for pastries.

Professional Baking: Industry Standards and Practices

Baker's percentage is a critical industry standard in professional baking, providing precise and scalable formulations by expressing each ingredient as a ratio of flour weight, enabling consistency across batch sizes. Unlike cup measurements, which vary by ingredient density and are less accurate, baker's percentage ensures exact hydration levels and ingredient balance essential for dough quality and texture. This system supports efficient recipe scaling, quality control, and reproducibility in commercial baking operations.

Choosing the Right Method for Your Pastry Recipe

Baker's percentage offers precise control over ingredient ratios by expressing each component as a percentage of the total flour weight, ensuring consistent dough hydration and texture. Cup measurements provide convenience and speed but can lead to variability due to differences in ingredient density and packing. For professional or complex pastry recipes, baker's percentage is preferred to maintain accuracy and reproducibility, while cup measurements suit casual baking where exact precision is less critical.

Baker’s Percentage vs Cup Measurements for dough formulation Infographic

cookingdif.com

cookingdif.com