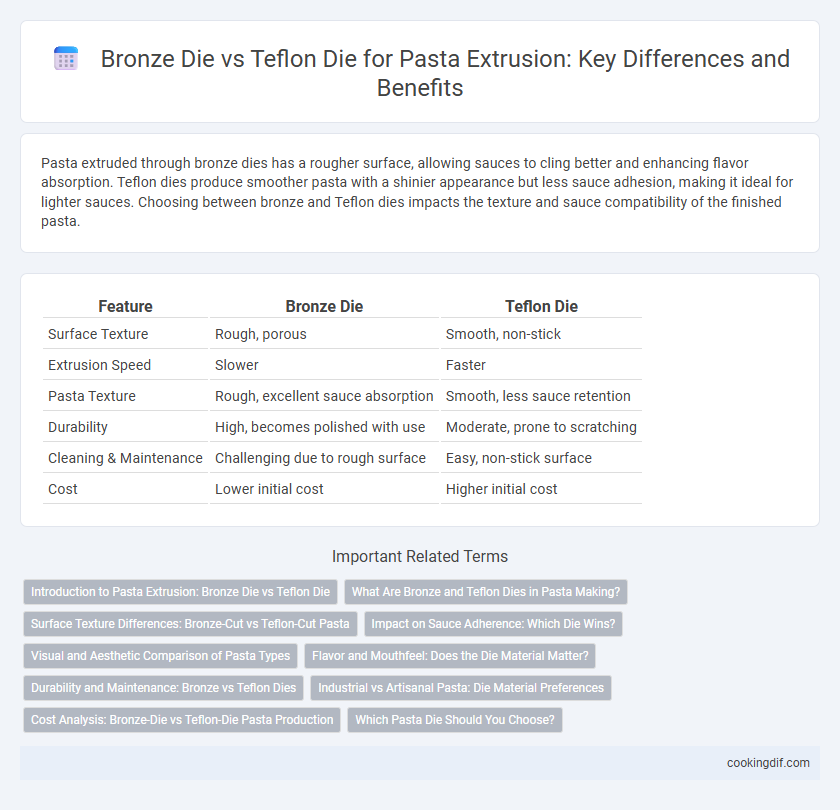

Pasta extruded through bronze dies has a rougher surface, allowing sauces to cling better and enhancing flavor absorption. Teflon dies produce smoother pasta with a shinier appearance but less sauce adhesion, making it ideal for lighter sauces. Choosing between bronze and Teflon dies impacts the texture and sauce compatibility of the finished pasta.

Table of Comparison

| Feature | Bronze Die | Teflon Die |

|---|---|---|

| Surface Texture | Rough, porous | Smooth, non-stick |

| Extrusion Speed | Slower | Faster |

| Pasta Texture | Rough, excellent sauce absorption | Smooth, less sauce retention |

| Durability | High, becomes polished with use | Moderate, prone to scratching |

| Cleaning & Maintenance | Challenging due to rough surface | Easy, non-stick surface |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Pasta Extrusion: Bronze Die vs Teflon Die

Pasta extrusion involves shaping dough through dies that impact texture and surface quality, with bronze dies producing a rougher surface ideal for holding sauces. Teflon dies create smoother pasta surfaces, resulting in a sleek appearance but less sauce adhesion. The choice between bronze and Teflon dies directly influences pasta texture, cooking behavior, and sauce compatibility.

What Are Bronze and Teflon Dies in Pasta Making?

Bronze and Teflon dies are essential tools in pasta extrusion, shaping dough into various pasta forms with distinct textures. Bronze dies, made from porous bronze, create rougher surfaces that hold sauces better and contribute to a traditional, artisanal texture. Teflon dies offer smoother surfaces, producing pasta with a silky finish and a more uniform shape, favored for consistent cooking and sleek presentation.

Surface Texture Differences: Bronze-Cut vs Teflon-Cut Pasta

Bronze die pasta features a rough, porous surface that better captures sauces, enhancing flavor absorption and providing a traditional al dente bite. In contrast, Teflon die pasta has a smooth, glossy finish that offers a slick texture but less sauce adherence, often resulting in a softer mouthfeel. The choice between bronze-cut and Teflon-cut pasta significantly impacts sauce retention and overall dining experience, influencing regional pasta preferences and cooking outcomes.

Impact on Sauce Adherence: Which Die Wins?

Bronze die pasta features a rough, porous surface that enhances sauce adherence by allowing sauces to cling better, creating a more flavorful eating experience. Teflon die pasta, with its smooth and glossy finish, tends to repel sauce, resulting in a less coated dish that may feel less rich. For dishes where sauce adherence is crucial, bronze die pasta consistently outperforms Teflon die pasta in delivering robust flavor and texture.

Visual and Aesthetic Comparison of Pasta Types

Bronze die extrusion creates pasta with a rougher surface texture that better holds sauces, giving it a traditional, artisan appearance favored in high-quality Italian cuisine. Teflon die extrusion produces pasta with a smoother, shinier finish, which looks more uniform and polished but may be perceived as less authentic. The porous surface of bronze die pasta enhances sauce adherence and visual appeal, making it preferred for rustic pasta dishes.

Flavor and Mouthfeel: Does the Die Material Matter?

Bronze die pasta features a rougher surface that enhances sauce adhesion and creates a more robust mouthfeel, contributing to a richer flavor experience. Teflon die pasta, with its smooth texture, results in a silky bite but may hold less sauce, subtly affecting flavor intensity. The choice of die material significantly influences the tactile feel and sauce retention, thereby impacting overall pasta taste.

Durability and Maintenance: Bronze vs Teflon Dies

Bronze dies offer superior durability due to their hardness and resistance to wear, making them ideal for long-term pasta extrusion. Teflon dies require less maintenance because their non-stick surface reduces dough buildup, but they tend to wear out faster under continuous use. Choosing between bronze and Teflon dies depends on balancing longevity with ease of cleaning in pasta production.

Industrial vs Artisanal Pasta: Die Material Preferences

Industrial pasta production favors Teflon dies for their non-stick properties and faster extrusion rates, optimizing high-volume output and uniform shapes. Artisanal pasta makers prefer bronze dies, which create a rougher surface texture that enhances sauce adhesion and delivers a more traditional, handcrafted appeal. The choice between bronze and Teflon dies directly impacts pasta texture, appearance, and market positioning in industrial versus artisanal settings.

Cost Analysis: Bronze-Die vs Teflon-Die Pasta Production

Bronze-die pasta typically incurs higher production costs due to increased wear and slower extrusion speeds, resulting in more frequent die replacements and higher energy consumption. Teflon-die pasta offers cost advantages with reduced maintenance requirements and faster extrusion rates, enhancing overall manufacturing efficiency. However, bronze-die pasta often commands premium pricing due to its superior texture and surface roughness, balancing its higher production expenses.

Which Pasta Die Should You Choose?

Bronze dies create pasta with a rougher texture that holds sauce better, making them ideal for traditional Italian dishes, while Teflon dies produce smoother pasta that cooks faster and is easier to clean. Bronze dies are preferred by artisanal pasta makers for their ability to absorb sauces more effectively, enhancing flavor and authenticity. Selecting between bronze and Teflon dies depends on whether texture and sauce adherence or ease of production and maintenance are more important to your pasta-making process.

Bronze die vs Teflon die for extrusion Infographic

cookingdif.com

cookingdif.com