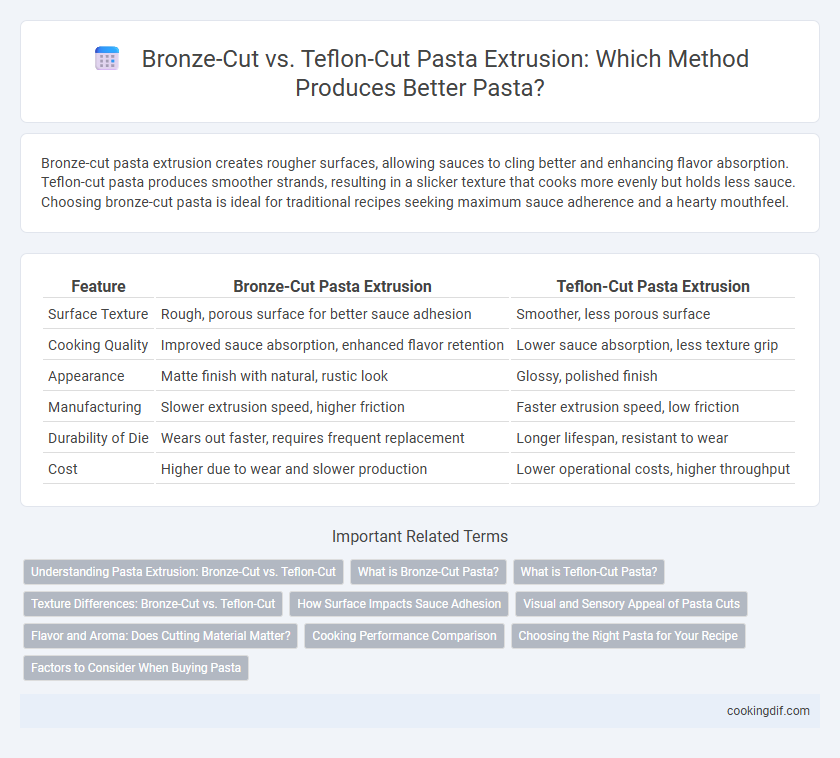

Bronze-cut pasta extrusion creates rougher surfaces, allowing sauces to cling better and enhancing flavor absorption. Teflon-cut pasta produces smoother strands, resulting in a slicker texture that cooks more evenly but holds less sauce. Choosing bronze-cut pasta is ideal for traditional recipes seeking maximum sauce adherence and a hearty mouthfeel.

Table of Comparison

| Feature | Bronze-Cut Pasta Extrusion | Teflon-Cut Pasta Extrusion |

|---|---|---|

| Surface Texture | Rough, porous surface for better sauce adhesion | Smoother, less porous surface |

| Cooking Quality | Improved sauce absorption, enhanced flavor retention | Lower sauce absorption, less texture grip |

| Appearance | Matte finish with natural, rustic look | Glossy, polished finish |

| Manufacturing | Slower extrusion speed, higher friction | Faster extrusion speed, low friction |

| Durability of Die | Wears out faster, requires frequent replacement | Longer lifespan, resistant to wear |

| Cost | Higher due to wear and slower production | Lower operational costs, higher throughput |

Understanding Pasta Extrusion: Bronze-Cut vs. Teflon-Cut

Bronze-cut pasta features a rough, porous surface created by extruding dough through bronze dies, enhancing sauce adhesion and delivering traditional texture. Teflon-cut pasta employs smooth, non-stick Teflon-coated dies, producing a sleek finish that reduces sticking during cooking but offers less sauce retention. Choosing between bronze-cut and Teflon-cut affects the pasta's mouthfeel and ability to hold sauces, influencing culinary applications and taste experience.

What is Bronze-Cut Pasta?

Bronze-cut pasta is produced using bronze dies that create a rough, porous surface, allowing sauce to cling better for enhanced flavor absorption. This traditional extrusion method contrasts with Teflon-cut techniques, which yield smoother pasta with less texture. The durability of bronze-cut pasta often results in a more authentic al dente texture, preferred in artisanal and high-quality pasta products.

What is Teflon-Cut Pasta?

Teflon-cut pasta refers to pasta shapes produced using Teflon-coated dies during the extrusion process, resulting in smoother surfaces compared to bronze-cut pasta. This smooth texture helps pasta cook more evenly and prevents sauces from clinging as effectively, offering a different mouthfeel and experience. The non-stick properties of Teflon dies also contribute to increased production efficiency and easier maintenance in pasta manufacturing.

Texture Differences: Bronze-Cut vs. Teflon-Cut

Bronze-cut pasta is produced using bronze dies that create a rough and porous surface, allowing sauces to adhere better and enhancing the overall texture of the dish. Teflon-cut pasta, made with non-stick Teflon dies, results in a smoother, more uniform surface that offers a silkier mouthfeel but may cause sauces to slide off more easily. The choice between bronze-cut and Teflon-cut pasta significantly impacts sauce retention and the tactile experience, with bronze-cut preferred for traditional, rustic pasta textures.

How Surface Impacts Sauce Adhesion

Bronze-cut pasta features a rough, porous surface created by traditional bronze dies, which enhances sauce adhesion by allowing the sauce to cling more effectively to the pasta. Teflon-cut pasta, produced with smooth, non-stick Teflon dies, has a sleek texture that causes sauces to slide off more easily, resulting in a less intense flavor experience. Choosing bronze-cut pasta is ideal for thicker, chunkier sauces, as its texture captures and holds the sauce better, maximizing taste and mouthfeel.

Visual and Sensory Appeal of Pasta Cuts

Bronze-cut pasta features a rougher texture due to its use of bronze dies, allowing sauces to cling better and enhancing the overall flavor experience. Teflon-cut pasta, by contrast, has a smoother surface that results in a shinier appearance but less sauce adherence, which can lead to a milder sensory profile. The distinct roughness of bronze-cut pasta not only improves sauce retention but also adds a more authentic, artisanal visual appeal favored in traditional Italian cooking.

Flavor and Aroma: Does Cutting Material Matter?

Bronze-cut pasta extruders create a rougher surface that enhances sauce adhesion and intensifies pasta's flavor and aroma, resulting in a more authentic and robust taste experience. Teflon-cut extrusion produces a smoother finish, which can lead to a milder flavor profile as sauces tend to slide off more easily, diminishing the overall sensory impact. The porous texture from bronze-cut pasta significantly influences the absorption of aromatic compounds, making it a preferred choice for maximizing flavor and aroma retention.

Cooking Performance Comparison

Bronze-cut pasta features a rougher surface texture that enhances sauce adhesion and delivers a chewier bite, while Teflon-cut pasta is smoother and cooks more quickly but may cause sauces to slide off. The porous nature of bronze-cut pasta absorbs water more evenly during cooking, resulting in better al dente texture and reduced stickiness compared to Teflon-cut varieties. Chefs often prefer bronze-cut pasta for robust sauces and traditional recipes due to its superior ability to retain flavors and provide a satisfying mouthfeel.

Choosing the Right Pasta for Your Recipe

Bronze-cut pasta features a rough texture that better holds sauces, making it ideal for hearty or chunky dishes where sauce adherence is key. Teflon-cut pasta, with its smooth surface, offers a sleek appearance and is better suited for light, delicate sauces or salads. Selecting bronze-cut pasta enhances flavor absorption and texture, while teflon-cut works well for recipes prioritizing shape and presentation.

Factors to Consider When Buying Pasta

Bronze-cut pasta offers a rough texture that enhances sauce adhesion, while Teflon-cut pasta provides a smoother surface and faster production. When buying pasta, consider the desired texture, cooking time, and sauce pairing to match the pasta type. Traditional bronze-cut varieties are favored for artisanal quality and richer flavor absorption, whereas Teflon-cut pasta suits mass production and consistent shape.

Bronze-cut vs Teflon-cut for pasta extrusion Infographic

cookingdif.com

cookingdif.com