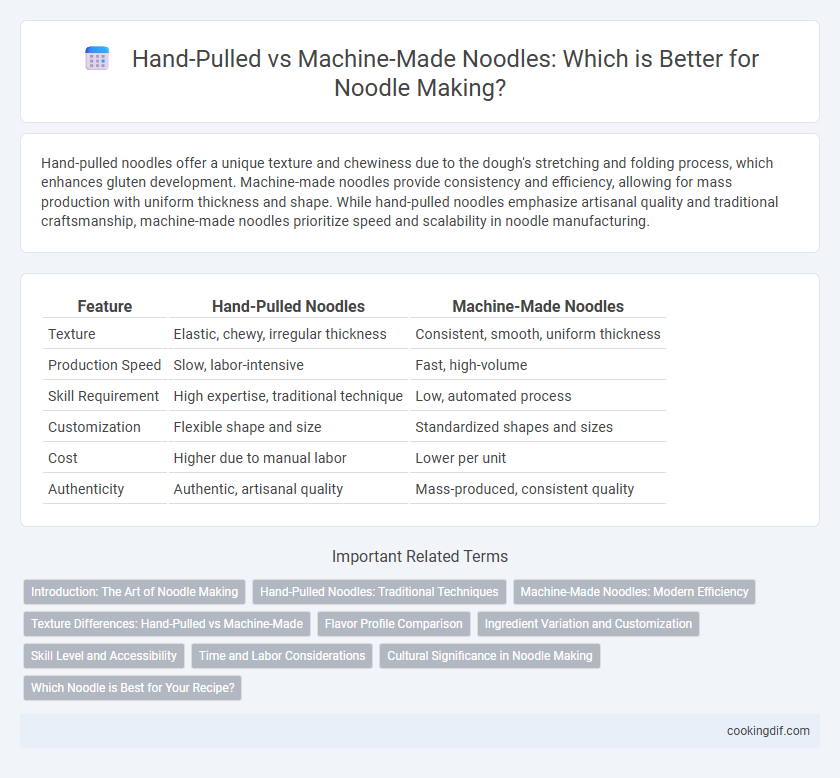

Hand-pulled noodles offer a unique texture and chewiness due to the dough's stretching and folding process, which enhances gluten development. Machine-made noodles provide consistency and efficiency, allowing for mass production with uniform thickness and shape. While hand-pulled noodles emphasize artisanal quality and traditional craftsmanship, machine-made noodles prioritize speed and scalability in noodle manufacturing.

Table of Comparison

| Feature | Hand-Pulled Noodles | Machine-Made Noodles |

|---|---|---|

| Texture | Elastic, chewy, irregular thickness | Consistent, smooth, uniform thickness |

| Production Speed | Slow, labor-intensive | Fast, high-volume |

| Skill Requirement | High expertise, traditional technique | Low, automated process |

| Customization | Flexible shape and size | Standardized shapes and sizes |

| Cost | Higher due to manual labor | Lower per unit |

| Authenticity | Authentic, artisanal quality | Mass-produced, consistent quality |

Introduction: The Art of Noodle Making

Hand-pulled noodles showcase traditional craftsmanship through skilled manipulation of dough, resulting in unique texture and elasticity that machines often cannot replicate. Machine-made noodles provide consistent shape and quicker production, catering to large-scale commercial demands with uniform quality. Both methods highlight distinct aspects of noodle-making art, balancing heritage with efficiency.

Hand-Pulled Noodles: Traditional Techniques

Hand-pulled noodles utilize traditional techniques that involve repeatedly stretching and folding dough by hand to achieve a distinctive chewy texture and uniform thickness. This artisanal process preserves the dough's elasticity and enhances the noodle's flavor compared to machine-made varieties. Mastery of hand-pulling requires skill and precise control, making these noodles a prized culinary staple in Chinese cuisine.

Machine-Made Noodles: Modern Efficiency

Machine-made noodles leverage automated technology to produce consistent texture and uniform thickness at high speeds, enhancing overall efficiency in large-scale noodle production. Advanced machinery incorporates precise dough kneading and cutting mechanisms, reducing human error and increasing output volume. This modern process supports scalability and meets rising consumer demand with reliable quality control.

Texture Differences: Hand-Pulled vs Machine-Made

Hand-pulled noodles exhibit an irregular, chewy texture due to the variable tension and stretching during manual preparation, enhancing bite and elasticity. Machine-made noodles typically have a uniform, smoother texture resulting from consistent extrusion and cutting processes, which may lack the nuanced chewiness found in hand-pulled varieties. The distinct texture differences between hand-pulled and machine-made noodles significantly impact mouthfeel and culinary authenticity in traditional Asian dishes.

Flavor Profile Comparison

Hand-pulled noodles offer a distinctive chewy texture and rich, slightly irregular surface that enhances sauce absorption and intensifies flavor complexity. Machine-made noodles provide uniform thickness and a consistent bite, often resulting in a more neutral flavor profile that highlights accompanying ingredients. The artisanal stretching of hand-pulled noodles generally contributes to a deeper, more satisfying taste experience compared to the mechanical precision of machine production.

Ingredient Variation and Customization

Hand-pulled noodles allow for greater ingredient variation and customization by enabling chefs to incorporate diverse flours and additives like spinach powder or turmeric directly into the dough, resulting in unique textures and flavors. Machine-made noodles typically use standardized dough recipes with limited ingredient flexibility to ensure consistent production efficiency and uniform texture. The artisanal nature of hand-pulling supports personalized noodle thickness and chewiness, enhancing culinary innovation compared to the uniformity of machine processing.

Skill Level and Accessibility

Hand-pulled noodles require significant skill and years of practice to achieve the perfect texture and thickness, making them less accessible to beginners. Machine-made noodles, by contrast, offer consistent results with minimal expertise and are widely available for commercial and home use. This accessibility makes machine production ideal for large-scale manufacturing and everyday cooking.

Time and Labor Considerations

Hand-pulled noodles require extensive manual skill and significantly more time, often taking several minutes to stretch and fold each batch, which increases labor intensity and limits production capacity. Machine-made noodles drastically reduce preparation time by automating dough kneading and shaping, allowing mass production with minimal human intervention. The efficiency of machines supports higher output and consistency, making them ideal for commercial environments where time and labor costs are critical factors.

Cultural Significance in Noodle Making

Hand-pulled noodles embody centuries of cultural heritage and artisanal skill, reflecting traditional methods passed down through generations in Chinese cuisine. Machine-made noodles offer efficiency and consistency, catering to modern demands but often lack the nuanced texture and cultural authenticity found in hand-pulled variants. The cultural significance of hand-pulled noodles lies in the craftsmanship and ritual that celebrate regional identity and culinary artistry.

Which Noodle is Best for Your Recipe?

Hand-pulled noodles offer a chewy texture and irregular thickness, ideal for absorbing rich, hearty sauces in traditional Asian dishes. Machine-made noodles provide uniformity and consistency, perfect for quick cooking and recipes requiring precise portion control. Choosing between hand-pulled and machine-made noodles depends on the desired texture and authenticity of your recipe, with hand-pulled favored for artisanal dishes and machine-made suited for convenience and mass production.

Hand-pulled vs Machine-made for noodle making Infographic

cookingdif.com

cookingdif.com