Steam injection creates a moist oven environment that enhances crust development by promoting oven spring and producing a glossy, crisp exterior. Dutch ovens trap steam released from the dough itself, mimicking professional steam injection ovens and yielding a similarly well-developed crust. Both methods improve crust texture, but steam injection offers more control over humidity levels for consistent results.

Table of Comparison

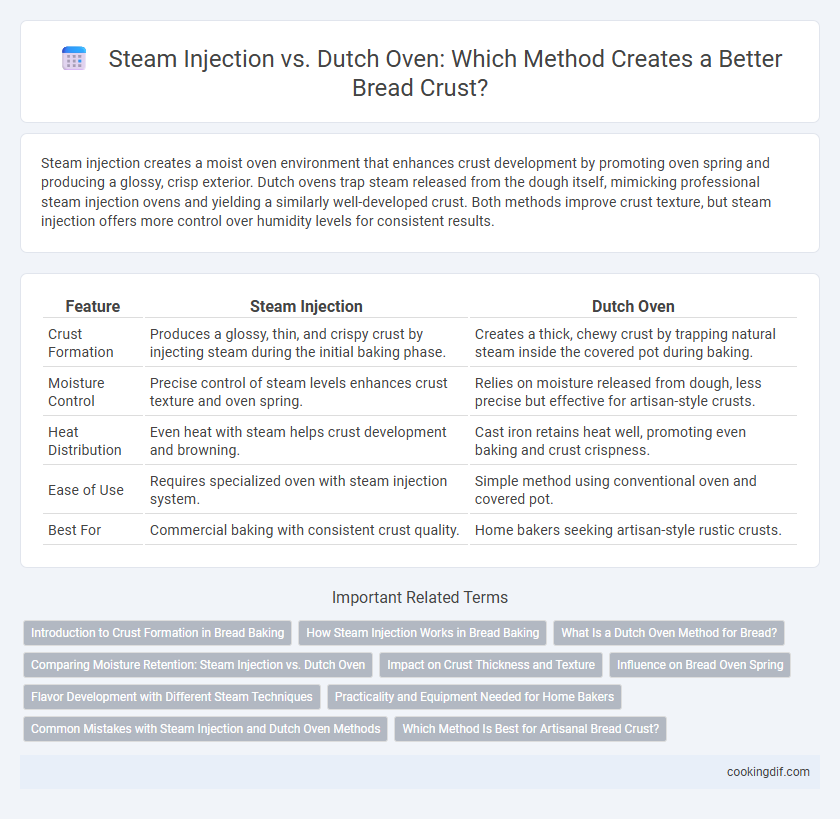

| Feature | Steam Injection | Dutch Oven |

|---|---|---|

| Crust Formation | Produces a glossy, thin, and crispy crust by injecting steam during the initial baking phase. | Creates a thick, chewy crust by trapping natural steam inside the covered pot during baking. |

| Moisture Control | Precise control of steam levels enhances crust texture and oven spring. | Relies on moisture released from dough, less precise but effective for artisan-style crusts. |

| Heat Distribution | Even heat with steam helps crust development and browning. | Cast iron retains heat well, promoting even baking and crust crispness. |

| Ease of Use | Requires specialized oven with steam injection system. | Simple method using conventional oven and covered pot. |

| Best For | Commercial baking with consistent crust quality. | Home bakers seeking artisan-style rustic crusts. |

Introduction to Crust Formation in Bread Baking

Steam injection introduces moisture during the initial baking phase, promoting a glossy, thin, and crisp crust by delaying starch gelatinization and enhancing oven spring. Dutch oven baking traps steam released by the dough itself, creating a humid environment that similarly aids crust development while simplifying the process for home bakers. Both methods optimize crust texture by controlling moisture and heat exposure crucial to Maillard reaction and caramelization.

How Steam Injection Works in Bread Baking

Steam injection in bread baking introduces moisture directly into the oven environment at the start of the baking process, delaying crust formation and allowing the dough to expand fully. This controlled humidity helps gelatinize the starches on the bread's surface, creating a glossy, thin, and crisp crust. Unlike a Dutch oven that traps steam released from the dough itself, steam injection systems can precisely regulate humidity levels for consistent crust development in commercial baking.

What Is a Dutch Oven Method for Bread?

The Dutch oven method for bread baking involves placing the dough inside a preheated, heavy, lidded pot which traps steam released during baking, promoting optimal crust formation and oven spring. This technique mimics the steam injection process in professional ovens by creating a humid environment that keeps the crust moist initially, allowing it to expand before hardening into a crisp, golden outer layer. The sealed environment of a Dutch oven enhances heat distribution and moisture retention, resulting in artisanal-style loaf crusts with rich texture and color.

Comparing Moisture Retention: Steam Injection vs. Dutch Oven

Steam injection in professional ovens enhances crust formation by delivering precise humidity levels during baking, resulting in a crisp, shiny crust and optimal oven spring due to better moisture retention on the dough's surface. Dutch ovens trap steam released by the dough itself within a closed environment, creating a humid microclimate that encourages gelatinization of the crust and prevents premature drying, though with less control over humidity compared to steam injection systems. While steam injection offers consistent moisture regulation for uniform crust texture, the Dutch oven method provides a cost-effective alternative with sufficient moisture retention for artisan-style breads.

Impact on Crust Thickness and Texture

Steam injection during baking produces a thinner, crisper crust by creating a humid environment that delays crust formation, allowing greater oven spring and a glossy finish. In contrast, baking bread in a Dutch oven traps steam naturally, resulting in a thicker, chewier crust with a rustic texture due to the sealed, moist heat environment. The choice between steam injection and Dutch oven methods significantly impacts the crust's thickness and texture, influencing bread type and desired final qualities.

Influence on Bread Oven Spring

Steam injection enhances crust formation by maintaining surface moisture, promoting a glossy, crispy exterior and maximizing oven spring through improved dough expansion. Dutch ovens trap natural steam released from the dough, creating a humid environment that supports crust development and oven spring but with less controlled moisture compared to professional steam injection. Bread baked with steam injection typically shows greater volume and a lighter crumb due to superior oven spring dynamics.

Flavor Development with Different Steam Techniques

Steam injection ovens create a humid environment that enhances crust formation by promoting Maillard reactions and caramelization, resulting in a deeply flavored, glossy crust. Dutch ovens trap steam released from the dough itself, producing a similar but subtler effect that encourages a chewy, artisan-style crust with complex textured flavors. Variations in steam duration and intensity directly influence the crust's thickness, crunch, and flavor profile, making oven choice and steam control critical for flavor development in artisanal bread.

Practicality and Equipment Needed for Home Bakers

Steam injection ovens require specialized equipment to release moisture during the initial baking phase, which can be costly and complex for home bakers. Dutch ovens, on the other hand, are affordable, widely available, and create a self-contained steam environment by trapping moisture from the dough, resulting in a crisp crust. For practicality, Dutch ovens offer a convenient, low-tech method to achieve bakery-quality crust without the need for professional steam injection systems.

Common Mistakes with Steam Injection and Dutch Oven Methods

Common mistakes with steam injection include adding excessive moisture, which can lead to a soggy crust, and timing the steam release improperly, inhibiting proper oven spring. When using a Dutch oven, failing to preheat it thoroughly or removing the lid too early can cause uneven crust texture and insufficient caramelization. Both methods require precise control over moisture and temperature to achieve a crisp, well-developed crust.

Which Method Is Best for Artisanal Bread Crust?

Steam injection in professional ovens creates a humid environment that promotes a shiny, crackly crust by delaying crust formation and allowing the bread to expand fully. Dutch ovens trap moisture released from the dough during baking, creating a steam effect that yields a thick, chewy crust with rustic blistering. For artisanal bread crust, choosing between steam injection and a Dutch oven depends on access to professional equipment and the desired crust texture--steam injection offers precision, while Dutch ovens provide home baker convenience with excellent crust results.

Steam injection vs Dutch oven for crust formation Infographic

cookingdif.com

cookingdif.com