Oil-blanching enhances noodle texture by coating strands with a thin layer of oil, preventing clumping and adding a subtle richness to the flavor profile. Dry-roasting, on the other hand, imparts a toasty aroma and crispy finish while reducing moisture content for extended shelf life. Both methods influence noodle mouthfeel and preservation, with oil-blanching favoring softness and dry-roasting promoting crunchiness.

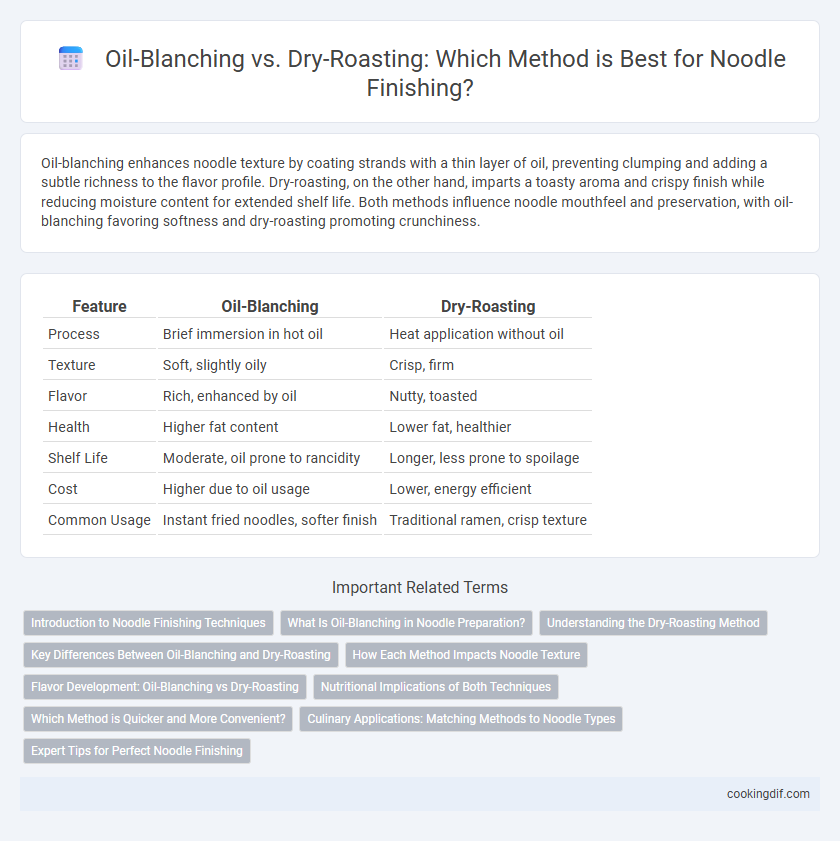

Table of Comparison

| Feature | Oil-Blanching | Dry-Roasting |

|---|---|---|

| Process | Brief immersion in hot oil | Heat application without oil |

| Texture | Soft, slightly oily | Crisp, firm |

| Flavor | Rich, enhanced by oil | Nutty, toasted |

| Health | Higher fat content | Lower fat, healthier |

| Shelf Life | Moderate, oil prone to rancidity | Longer, less prone to spoilage |

| Cost | Higher due to oil usage | Lower, energy efficient |

| Common Usage | Instant fried noodles, softer finish | Traditional ramen, crisp texture |

Introduction to Noodle Finishing Techniques

Oil-blanching enhances noodle texture by evenly coating strands with oil, preventing stickiness and improving mouthfeel. Dry-roasting, a traditional method, imparts a toasted aroma and firmer texture, extending shelf-life through moisture reduction. Both techniques are integral to optimizing noodle quality, catering to diverse culinary preferences.

What Is Oil-Blanching in Noodle Preparation?

Oil-blanching in noodle preparation involves briefly immersing noodles in hot oil to enhance texture and flavor by sealing surface starches and preventing clumping. This technique creates a slightly crispy exterior while maintaining a soft interior, improving overall mouthfeel and shelf stability. Compared to dry-roasting, oil-blanching imparts a richer taste and a glossy appearance to the finished noodles.

Understanding the Dry-Roasting Method

Dry-roasting noodles involves heating them in a dry pan without oil, which enhances their texture by creating a crisp outer layer while preserving the noodle's natural flavor. This method reduces grease content, making the noodles lighter and healthier compared to oil-blanched variants. Dry-roasting also improves shelf life by minimizing moisture retention, preventing sogginess during storage and cooking.

Key Differences Between Oil-Blanching and Dry-Roasting

Oil-blanching involves briefly submerging noodles in hot oil, resulting in enhanced moisture retention, improved texture, and a glossy appearance, while dry-roasting exposes noodles to hot air or a dry surface, promoting crispiness and a roasted flavor without added fat. Oil-blanched noodles typically exhibit higher caloric content and a softer bite, contrasting with the lighter, crunchier outcome of dry-roasted noodles. The choice between methods impacts shelf life, with oil-blanched noodles being more prone to oxidation and rancidity compared to the longer-lasting dry-roasted variety.

How Each Method Impacts Noodle Texture

Oil-blanching imparts a smoother, more elastic texture to noodles by coating them in a thin layer of oil, which reduces surface stickiness and enhances moisture retention. Dry-roasting produces a firmer, chewier texture by causing slight dehydration and surface browning, resulting in a more distinct bite. The choice between oil-blanching and dry-roasting directly affects the noodle's mouthfeel and cooking performance, influencing consumer preference based on texture requirements.

Flavor Development: Oil-Blanching vs Dry-Roasting

Oil-blanching enhances noodle flavor by imparting a rich, savory taste due to the absorption of fats, promoting Maillard reactions that deepen complexity and improve mouthfeel. In contrast, dry-roasting develops a nutty, toasted aroma through direct heat exposure, intensifying surface browning without additional fat incorporation, which results in a crisper texture. Selecting oil-blanching or dry-roasting techniques directly impacts the sensory profile, with oil-blanching favoring richness and moisture retention while dry-roasting emphasizes aromatic crispness and dryness.

Nutritional Implications of Both Techniques

Oil-blanching preserves moisture and enhances flavor in noodles while increasing fat content and calorie density, impacting their nutritional profile. Dry-roasting reduces moisture, resulting in a lower fat content and potentially higher antioxidant levels due to Maillard reactions. Choosing between these techniques influences the balance of calories, fat, and bioactive compounds in the final noodle product.

Which Method is Quicker and More Convenient?

Oil-blanching finishes noodles faster by simultaneously cooking and flavoring while preventing stickiness, requiring less time than dry-roasting which involves longer heating and constant stirring to avoid burning. The convenience of oil-blanching stems from its one-step process and reduced monitoring, making it ideal for high-volume production. Dry-roasting offers enhanced texture and aroma but demands more attention and time, making oil-blanching the quicker, more convenient method for noodle finishing.

Culinary Applications: Matching Methods to Noodle Types

Oil-blanching enhances the texture and flavor of fresh or egg noodles by providing a smooth, glossy finish and preventing stickiness during cooking. Dry-roasting suits sturdier, dried wheat noodles, imparting a nutty aroma and a firmer bite ideal for stir-fry dishes. Selecting the finishing technique based on noodle type optimizes taste and mouthfeel in various culinary applications.

Expert Tips for Perfect Noodle Finishing

Oil-blanching enhances noodle texture by locking in moisture and providing a glossy finish that prevents sticking, making it ideal for dishes requiring a smooth, elastic bite. Dry-roasting intensifies flavor through Maillard reactions, creating a slightly crisp exterior while reducing oil content, suitable for healthier recipes or stir-fry applications. Experts recommend selecting oil-blanching for tender, chewy noodles and dry-roasting when a firmer, toasted finish is desired, adjusting heat and time precisely to avoid overcooking.

Oil-blanching vs dry-roasting for noodle finishing Infographic

cookingdif.com

cookingdif.com