Hand-folded dumplings offer a unique texture and artisanal charm, showcasing skilled craftsmanship with each pleat carefully formed by hand. Mold-pressed dumplings provide consistent shapes and uniform cooking times, ideal for mass production or quick preparation without sacrificing quality. Choosing between hand-folded and mold-pressed depends on the desired authenticity and efficiency in dumpling making.

Table of Comparison

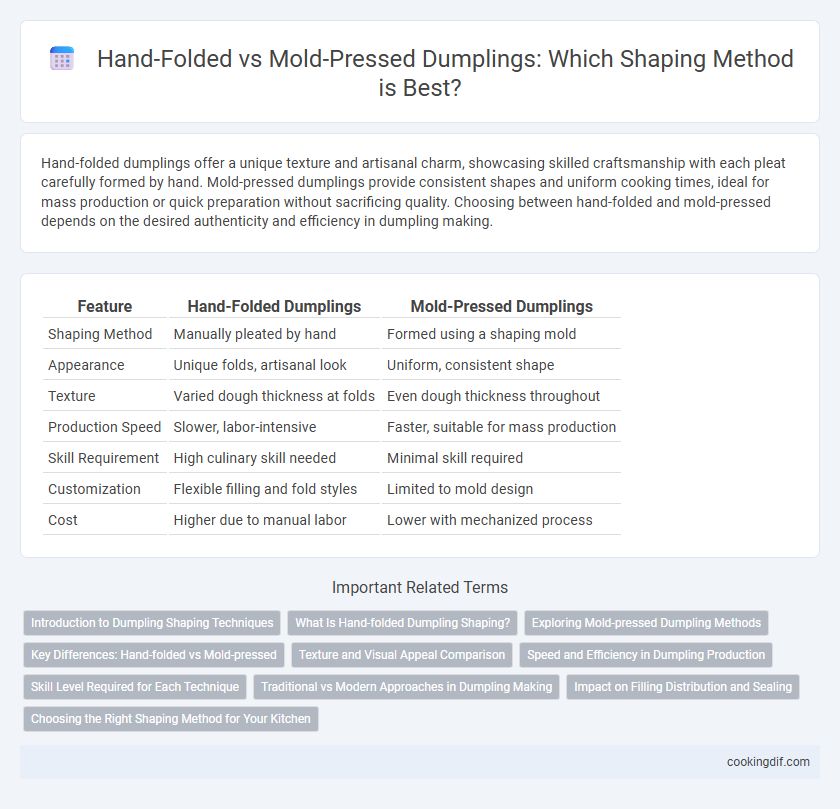

| Feature | Hand-Folded Dumplings | Mold-Pressed Dumplings |

|---|---|---|

| Shaping Method | Manually pleated by hand | Formed using a shaping mold |

| Appearance | Unique folds, artisanal look | Uniform, consistent shape |

| Texture | Varied dough thickness at folds | Even dough thickness throughout |

| Production Speed | Slower, labor-intensive | Faster, suitable for mass production |

| Skill Requirement | High culinary skill needed | Minimal skill required |

| Customization | Flexible filling and fold styles | Limited to mold design |

| Cost | Higher due to manual labor | Lower with mechanized process |

Introduction to Dumpling Shaping Techniques

Hand-folded dumplings are crafted by carefully pleating the dough by hand, resulting in unique textures and a traditional aesthetic. Mold-pressed dumplings utilize specialized tools to create uniform shapes quickly, ensuring consistency in size and cooking. Each shaping technique impacts the dumpling's texture, cooking time, and visual appeal, making the choice important for desired culinary outcomes.

What Is Hand-folded Dumpling Shaping?

Hand-folded dumpling shaping involves manually pleating the dough around the filling, creating intricate folds that ensure a secure seal and distinctive texture. This traditional technique allows for greater control over thickness and aesthetic variations, resulting in a dumpling that cooks evenly and holds its juices better. Skilled artisans often use hand-folding to produce signature shapes that enhance presentation and taste, distinguishing them from uniform mold-pressed dumplings.

Exploring Mold-pressed Dumpling Methods

Mold-pressed dumpling methods utilize specialized tools to achieve uniform shapes and consistent thickness, enhancing cooking precision and presentation quality. These molds reduce preparation time compared to hand-folded techniques, making them ideal for mass production in commercial kitchens. The precise shaping also improves filling distribution, resulting in evenly cooked dumplings with optimal texture and flavor retention.

Key Differences: Hand-folded vs Mold-pressed

Hand-folded dumplings showcase artisanal craftsmanship with each pleat carefully pinched, resulting in unique texture and shape that enhances flavor absorption during cooking. Mold-pressed dumplings offer uniformity and speed, ideal for mass production while ensuring consistent size and shape for even cooking. The key difference lies in the balance between traditional, detailed handwork and efficient, standardized molding techniques.

Texture and Visual Appeal Comparison

Hand-folded dumplings offer a unique texture characterized by delicate, layered pleats that create a tender bite and artisan visual appeal, emphasizing craftsmanship. Mold-pressed dumplings provide uniform shape and consistent thickness, resulting in a smooth, even texture and a polished, symmetrical appearance ideal for mass production. The choice between the two methods impacts both sensory experience and aesthetic presentation, with hand-folded styles favored for tradition and mold-pressed for efficiency.

Speed and Efficiency in Dumpling Production

Hand-folded dumplings offer intricate shapes and texture but require skilled labor and significantly more time per piece, impacting overall production speed. Mold-pressed dumplings dramatically increase efficiency by automating uniform shaping, enabling higher output rates and consistency essential for large-scale manufacturing. Balancing quality and speed, many commercial producers favor mold-pressed techniques to optimize throughput without compromising product standard.

Skill Level Required for Each Technique

Hand-folded dumplings demand high dexterity and precision, as each pleat requires careful manipulation to ensure a uniform shape and even cooking. Mold-pressed dumplings streamline the shaping process, making them accessible to beginners with minimal training, as the press provides consistent size and sealing with less manual skill. Both techniques impact texture and presentation, but hand-folded requires significant practice to perfect, while mold-pressed prioritizes efficiency and consistency.

Traditional vs Modern Approaches in Dumpling Making

Hand-folded dumplings showcase traditional craftsmanship with intricate pleats that enhance texture and flavor absorption, reflecting regional culinary heritage. Mold-pressed dumplings, favored in modern kitchens, offer consistent shapes and faster production, meeting high demand with uniform results. Both methods impact the eating experience, with hand-folding emphasizing artisanal quality while mold-pressing streamlines efficiency.

Impact on Filling Distribution and Sealing

Hand-folded dumplings create uneven filling distribution due to varied pleat tension, which can result in bursts or leaks during cooking. Mold-pressed dumplings ensure uniform filling spread and a consistent seal, reducing the risk of rupture and preserving the dumpling's shape. Proper sealing in mold-pressed dumplings enhances cooking stability and prevents filling from escaping, improving overall texture and flavor retention.

Choosing the Right Shaping Method for Your Kitchen

Hand-folded dumplings offer artisanal texture and unique shapes, enhancing flavor absorption and presentation, ideal for kitchens valuing craftsmanship. Mold-pressed dumplings provide uniformity and faster production, suitable for high-volume cooking environments requiring consistency. Selecting the right shaping method depends on your kitchen's focus on quality versus efficiency and available labor resources.

Hand-folded vs Mold-pressed for shaping Infographic

cookingdif.com

cookingdif.com